In the world of industrial manufacturing, the importance of stamping die alignment cannot be overstated. Proper alignment ensures that the stamping process is efficient, precise, and cost-effective. This article delves into why stamping die alignment is crucial for manufacturers, highlighting its impact on productivity, cost savings, and product quality.

Why is Stamping Die Alignment Crucial?

Stamping dies are integral components in the manufacturing process, used to shape and cut materials into desired forms. When these dies are not properly aligned, several issues can arise, including increased wear and tear, production delays, and product defects. Thus, understanding the importance of stamping die alignment is vital for maintaining operational efficiency.

The Role of Precision in Manufacturing

Precision is a cornerstone of manufacturing success. Properly aligned dies ensure that each stamped piece is uniform, meeting the exact specifications required by clients. This uniformity is critical in industries where precision is paramount, such as automotive and electronics manufacturing.

Impact on Product Quality

The quality of stamped products can suffer significantly when die alignment is off. Misalignment can lead to burrs, rough edges, and other defects that compromise the integrity of the final product. Therefore, maintaining proper die alignment is essential for ensuring high-quality outcomes.

Reducing Waste and Costs

Proper die alignment minimizes material waste, as the raw materials are used more efficiently. This reduction in waste translates to lower production costs, making the manufacturing process more sustainable and economically viable.

Enhancing Production Efficiency

Aligned stamping dies contribute to smoother production runs, reducing the likelihood of machine downtime. Downtime can be costly, leading to delays and lost revenue. By ensuring that dies are properly aligned, manufacturers can maintain a steady production pace, enhancing overall efficiency.

Role in Reducing Downtime

One of the biggest challenges in manufacturing is minimizing downtime. Misaligned dies can cause machines to malfunction, leading to unexpected stoppages. Tools like reducing downtime strategies can help address these issues.

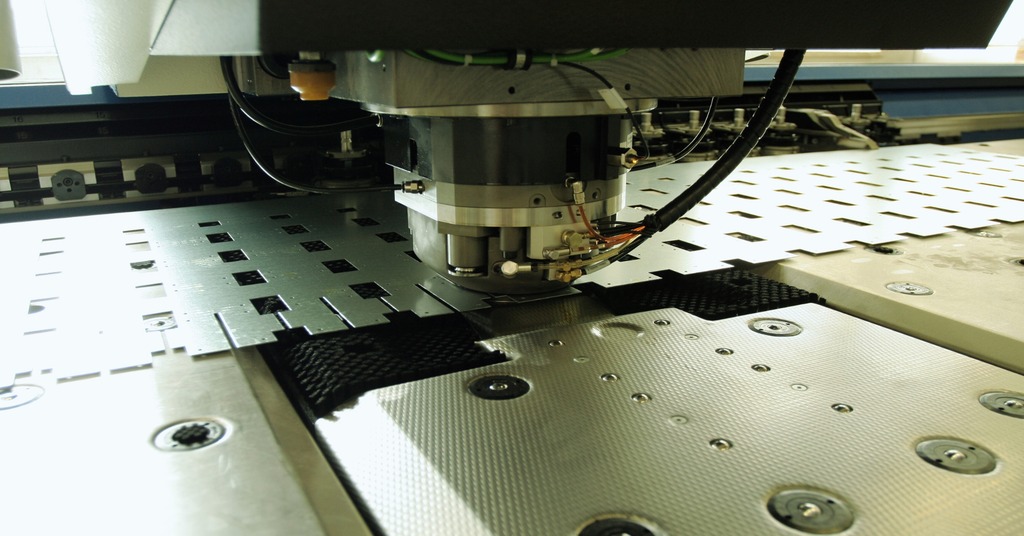

Technological Advancements in Die Alignment

Modern technology has introduced new tools and techniques for improving die alignment. Laser alignment tools and automated systems can significantly enhance precision and accuracy, reducing the margin for error in the alignment process.

Laser Alignment Tools

Laser tools provide real-time feedback on die alignment, allowing operators to make immediate adjustments. This technology not only improves accuracy but also reduces the time required to achieve proper alignment.

Automated Alignment Systems

Automated systems use sensors and computer algorithms to align dies with high precision. These systems can adjust for deviations in real-time, ensuring continuous alignment during production.

Training and Skill Development

Investing in employee training is crucial for maintaining proper die alignment. Skilled operators are better equipped to identify alignment issues and make necessary adjustments, preventing costly production errors.

Importance of Skilled Operators

Operators with expertise in die alignment can detect subtle misalignments that might go unnoticed. Their skills are invaluable in maintaining the efficiency and quality of the stamping process.

Case Study: Successful Alignment Strategies

Several manufacturers have reported significant improvements in productivity and quality after implementing advanced die alignment strategies. These case studies highlight the tangible benefits of focusing on alignment as a key component of the manufacturing process.

Real-World Example

A leading automotive manufacturer implemented laser alignment tools and saw a 20% reduction in production defects. This improvement not only enhanced product quality but also boosted customer satisfaction.

Challenges and Solutions in Die Alignment

While the importance of die alignment is clear, achieving it consistently can be challenging. Manufacturers often face obstacles such as equipment wear and operator errors. However, solutions such as regular maintenance and ongoing training can mitigate these challenges.

Overcoming Equipment Wear

Regular maintenance and timely replacement of worn-out components are essential for maintaining die alignment. Scheduled maintenance ensures that equipment operates at peak efficiency.

Addressing Operator Errors

Continuous training and the use of automated systems can significantly reduce operator errors, ensuring that dies remain aligned throughout the production process.

Future Trends in Die Alignment

As technology continues to evolve, new trends in die alignment are emerging. These trends promise to further enhance precision and efficiency in manufacturing.

Smart Manufacturing Technologies

Smart technologies, such as the Internet of Things (IoT), are being integrated into manufacturing processes to provide real-time data on die alignment. This information can be used to make proactive adjustments and maintain optimal alignment.

Predictive Maintenance

Predictive maintenance technologies use data analytics to foresee potential alignment issues before they occur, allowing for preemptive action. This approach helps minimize downtime and maintain production quality.

Conclusion

The importance of stamping die alignment in industrial manufacturing cannot be overstated. It plays a crucial role in ensuring product quality, reducing costs, and enhancing production efficiency. By embracing advanced technologies and investing in skilled operators, manufacturers can achieve optimal die alignment and gain a competitive edge in the industry.

FAQs

Why is die alignment important in stamping?

Proper die alignment is essential for ensuring precision, quality, and efficiency in the stamping process. It prevents defects and minimizes material waste.

How can technology improve die alignment?

Technological advancements like laser tools and automated systems enhance die alignment by providing real-time feedback and precise adjustments.

What are the challenges in maintaining die alignment?

Challenges include equipment wear and operator errors, which can be addressed through regular maintenance and training initiatives.

This article contains affiliate links. We may earn a commission at no extra cost to you.