In the rapidly evolving landscape of industrial manufacturing, smart sensors in stamping presses are becoming increasingly pivotal. These advanced technologies are not just transforming the way manufacturers operate but are also setting new standards in efficiency and precision. With the advent of smart sensors, stamping presses are now equipped to deliver unparalleled performance, ensuring that the production process is both seamless and highly efficient.

The integration of smart sensors within stamping presses is a testament to the incredible advancements in industrial technology. These sensors play a crucial role in monitoring and optimizing the entire stamping process, leading to reduced downtime and enhanced product quality. As industries continue to adopt these technologies, the future of manufacturing looks brighter and more promising than ever.

Understanding Stamping Presses

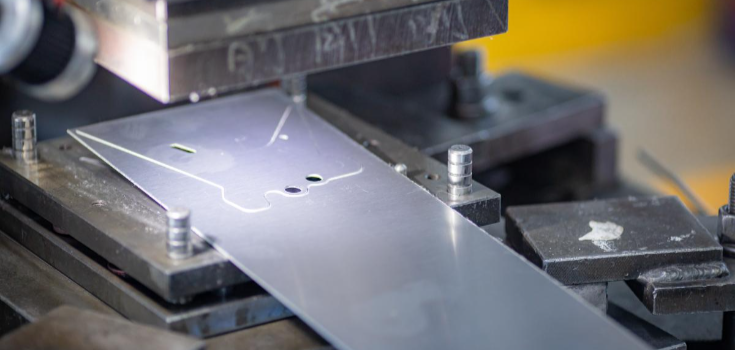

Stamping presses are a cornerstone in the manufacturing sector, utilized for shaping and cutting materials into desired forms. These presses are essential for producing a wide range of products, from automotive components to household appliances. The efficiency and precision of stamping presses are critical to the overall quality of the manufactured products. For a deeper understanding of metal stamping, you can explore this comprehensive guide.

The Role of Smart Sensors

Smart sensors are instrumental in enhancing the functionality of stamping presses. These sensors provide real-time data, allowing operators to monitor the pressing process closely. This data-driven approach helps in identifying any anomalies in the process, thereby preventing potential malfunctions and ensuring a smooth operation.

Types of Smart Sensors Used

There are various types of smart sensors that can be integrated into stamping presses, including pressure sensors, temperature sensors, and proximity sensors. Each type plays a unique role in monitoring different aspects of the press operation. Pressure sensors, for instance, monitor the force applied during the stamping process, while temperature sensors ensure that the machinery operates within optimal temperature ranges.

Advantages of Smart Sensors

The implementation of smart sensors in stamping presses offers numerous advantages. These include improved accuracy, enhanced safety, and increased operational efficiency. By providing real-time feedback, smart sensors enable operators to make informed decisions, leading to reduced material waste and lower production costs.

Impact on Industrial Manufacturing

The introduction of smart sensors has significantly impacted industrial manufacturing. They have revolutionized the way manufacturers approach production, promoting a shift towards more sustainable and efficient practices. With the ability to monitor processes in real-time, manufacturers can now ensure the highest levels of quality control.

Efficiency and Cost Reduction

One of the most significant benefits of integrating smart sensors into stamping presses is the potential for cost reduction. By minimizing downtime and reducing waste, manufacturers can achieve substantial savings. Additionally, the enhanced precision offered by smart sensors leads to fewer defects, further contributing to cost efficiency.

Enhancing Product Quality

Product quality is a top priority for manufacturers, and smart sensors play a crucial role in maintaining high standards. By providing continuous feedback, these sensors ensure that every product meets the required specifications, leading to higher customer satisfaction and brand loyalty.

The Future of Stamping Presses

As technology continues to advance, the future of stamping presses looks promising. The integration of more sophisticated smart sensors is expected to further enhance the capabilities of these presses. Manufacturers are likely to see even greater improvements in efficiency, precision, and overall performance.

Emerging Trends

Several emerging trends are shaping the future of stamping presses. These include the adoption of IoT (Internet of Things) technologies, which enable seamless communication between different machinery components. Additionally, advancements in AI (Artificial Intelligence) are expected to further optimize the stamping process, making it more efficient and reliable.

Challenges and Opportunities

While the integration of smart sensors presents numerous opportunities, it also comes with its set of challenges. Manufacturers must invest in training their workforce to effectively utilize these technologies. Additionally, the initial cost of integrating smart sensors can be high, but the long-term benefits often outweigh these costs.

Conclusion

The advent of smart sensors in stamping presses marks a significant milestone in the field of industrial manufacturing. These technologies are not only enhancing the efficiency and precision of manufacturing processes but are also paving the way for a more sustainable and cost-effective future. As industries continue to embrace these advancements, the potential for growth and innovation is immense.

FAQs

What are the main benefits of using smart sensors in stamping presses?

Smart sensors offer numerous benefits, including improved accuracy, enhanced safety, and increased operational efficiency. They provide real-time feedback, enabling operators to make informed decisions that reduce material waste and production costs.

How do smart sensors improve product quality?

By providing continuous feedback, smart sensors ensure that every product meets the required specifications, leading to higher customer satisfaction and brand loyalty.

What challenges do manufacturers face when integrating smart sensors?

Manufacturers face challenges such as the initial cost of integration and the need for workforce training. However, the long-term benefits often outweigh these challenges, making smart sensors a worthwhile investment.

For more insights into the world of metalworking and innovative practices, visit Metal Mosaic Garden Projects and explore the different projects that utilize modern technologies in metal art.

This article contains affiliate links. We may earn a commission at no extra cost to you.