The world of manufacturing is continuously evolving. Among the latest advancements is servo press technology in stamping presses. This technology is reshaping how manufacturers approach metal stamping, offering greater precision and efficiency. In this article, we will delve into the intricacies of servo press technology and its significant impact on the stamping industry.

What is Servo Press Technology?

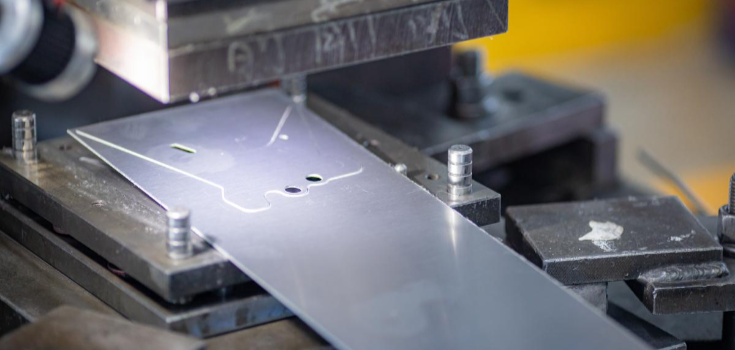

Servo press technology refers to a type of press that uses a servo motor to control the movement and force of the press. Unlike traditional mechanical presses, which rely on fixed mechanical linkages, servo presses offer variable control over speed and force. This flexibility allows for superior precision and efficiency during the stamping process.

The Evolution of Stamping Presses

Stamping presses have been around for decades, primarily using mechanical or hydraulic systems. However, with the advent of servo press technology, the industry has witnessed a significant transformation. Servo presses bring a host of benefits, including increased accuracy, energy efficiency, and reduced noise levels.

Advantages of Servo Presses

Servo presses offer several advantages over traditional press systems. Key benefits include:

- Precision: The ability to control movement and force with high accuracy.

- Energy Efficiency: Servo motors consume less energy than hydraulic systems.

- Flexibility: Easily adjust press parameters for different applications.

- Reduced Noise: Quieter operation compared to mechanical presses.

Applications of Servo Press Technology in Stamping Presses

Servo press technology is widely used in various industries, including automotive, aerospace, and electronics. It is particularly beneficial where high precision and consistency are required, such as in the production of intricate metal components.

Automotive Industry

In the automotive industry, servo press technology is pivotal in producing parts with tight tolerances. This capability is critical for ensuring the safety and performance of vehicles. Learn more about quality control in stamping production.

Aerospace Industry

The aerospace sector demands high precision and reliability. Servo presses provide the necessary accuracy to manufacture components that meet stringent industry standards.

Comparing Servo and Traditional Presses

While both servo and traditional presses have their place in manufacturing, the choice between them depends on specific production needs. Servo presses offer greater control and flexibility, making them suitable for complex applications. On the other hand, traditional presses may be more cost-effective for simpler tasks.

Cost Considerations

Initially, servo presses may require a higher investment. However, their operational benefits, such as reduced energy consumption and increased production speed, often result in cost savings over time.

Future Trends in Servo Press Technology

The future of servo press technology in stamping presses looks promising. As technology advances, we can expect further improvements in speed, precision, and energy efficiency. Additionally, the integration of IoT and AI could lead to smart presses that optimize production processes autonomously.

Innovations on the Horizon

Manufacturers are continually seeking ways to enhance productivity. Innovations like real-time monitoring and adaptive control systems are set to revolutionize how servo presses operate.

Conclusion

Servo press technology is a game-changer in the stamping industry. It offers unparalleled precision, efficiency, and flexibility, making it an ideal choice for modern manufacturing. As the technology continues to evolve, its impact on the industry will only grow.

FAQs

What is the primary advantage of servo press technology?

Servo press technology offers superior precision and flexibility, allowing manufacturers to produce high-quality components with consistent accuracy.

How does servo press technology contribute to energy efficiency?

Servo presses use energy only when needed, unlike traditional systems that consume energy continuously. This results in significant energy savings.

Are servo presses suitable for all types of manufacturing?

While servo presses excel in applications requiring high precision, they may not be cost-effective for simpler tasks where traditional presses suffice.

For more information on metal stamping, visit National Material and IQS Directory.

This article contains affiliate links. We may earn a commission at no extra cost to you.