In the rapidly evolving world of industrial manufacturing, ensuring the safety of workers and the quality of products is paramount. One of the key areas where safety cannot be compromised is in the operation of stamping machines. Understanding and implementing safety standards for stamping machines is crucial for maintaining a safe and efficient workplace. This article delves into the various aspects of these standards and their importance.

Understanding Stamping Machines

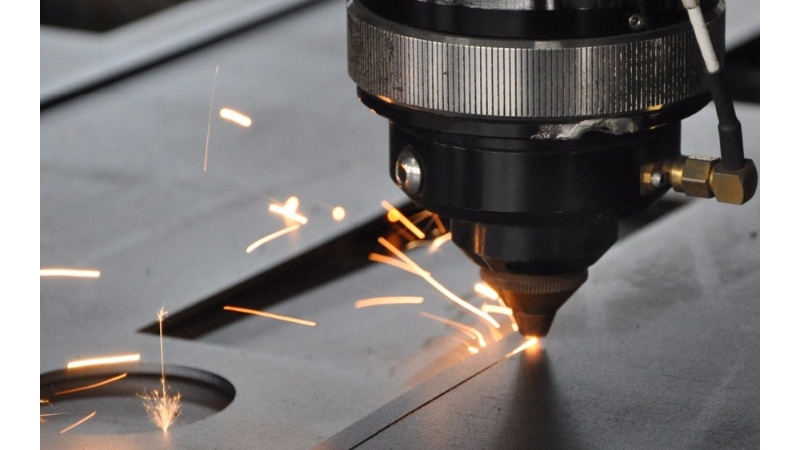

Stamping machines are vital in the manufacturing industry. They shape or cut metal into specific forms using a die. These machines are used in various industries, from automotive to electronics, to create parts and components critical to the final product. However, due to their powerful nature, they pose significant safety risks if not properly managed.

The Importance of Safety Standards

Implementing safety standards for stamping machines is essential to prevent accidents and ensure the wellbeing of workers. These standards provide guidelines and best practices for operating stamping machines safely. They cover everything from machine maintenance to operator training, ensuring that every aspect of the machine’s operation is conducted safely.

Key Components of Safety Standards

Machine Maintenance

Regular maintenance of stamping machines is crucial. This includes checking for wear and tear, ensuring all parts are functioning correctly, and replacing any faulty components. By keeping machines in top condition, the risk of malfunctions and accidents is significantly reduced.

Operator Training

Proper training for machine operators is a fundamental aspect of safety standards for stamping machines. Operators should be well-versed in the machine’s operations, safety features, and emergency procedures. Continuous training programs can help keep operators informed about the latest safety protocols.

Safety Features

Stamping machines should be equipped with essential safety features such as emergency stop buttons, safety guards, and sensors. These features are designed to prevent accidents and protect operators from potential hazards.

Industry Regulations and Compliance

Adhering to industry regulations and standards set by organizations such as OSHA (Occupational Safety and Health Administration) is mandatory. These regulations are designed to enforce safety measures and protect workers in the manufacturing industry. Companies must ensure compliance to avoid penalties and ensure a safe working environment.

Benefits of Compliance

Compliance with safety standards not only ensures the safety of workers but also increases productivity and efficiency. A safe workplace reduces downtime caused by accidents and machine malfunctions. Additionally, it enhances the company’s reputation and fosters a positive work culture.

Challenges in Implementing Safety Standards

While the benefits of implementing safety standards for stamping machines are clear, there are challenges that companies may face. These include the cost of upgrading machines, training programs, and ensuring ongoing compliance. However, these challenges are outweighed by the long-term benefits of a safe and efficient workplace.

Overcoming Challenges

To overcome these challenges, companies can seek assistance from industry experts and consultants. They can provide valuable insights and strategies for implementing safety standards effectively. Additionally, investing in modern technologies and automation can enhance safety and productivity.

Case Studies and Success Stories

Several companies have successfully implemented safety standards for stamping machines and reaped the benefits. For instance, a leading automotive manufacturer reduced workplace accidents by 50% after introducing comprehensive safety protocols and training programs. These success stories highlight the importance and effectiveness of safety standards.

Future Trends in Stamping Machine Safety

The future of stamping machine safety is promising, with advancements in technology and automation playing a significant role. Smart machines equipped with advanced sensors and AI can detect potential hazards and prevent accidents before they occur. These innovations are set to revolutionize the industry and further enhance workplace safety.

Conclusion

In conclusion, understanding and implementing safety standards for stamping machines is crucial for ensuring a safe and productive workplace. By prioritizing safety, companies can protect their workers, enhance productivity, and maintain a positive reputation. As technology continues to evolve, the future of stamping machine safety looks bright, promising a safer and more efficient manufacturing industry.

FAQs

- What are the key safety features of stamping machines? Key safety features include emergency stop buttons, safety guards, and sensors designed to prevent accidents and protect operators.

- Why is operator training important? Operator training is essential to ensure that machine operators are well-versed in the machine’s operations, safety features, and emergency procedures, reducing the risk of accidents.

- How can companies overcome the challenges of implementing safety standards? Companies can seek assistance from industry experts and consultants, invest in modern technologies, and provide continuous training to effectively implement safety standards.

For more information on stamping machine safety and related topics, you can visit Aranda Tooling and Operator Training.

This article contains affiliate links. We may earn a commission at no extra cost to you.