In the ever-evolving world of industrial manufacturing, the need for efficient and cost-effective solutions is paramount. One such solution gaining traction is the retrofitting of stamping presses. This process not only enhances the lifespan of existing machinery but also significantly boosts productivity. For industrial manufacturers, understanding the intricacies of retrofitting can lead to substantial gains in both performance and profitability.

Understanding Stamping Presses

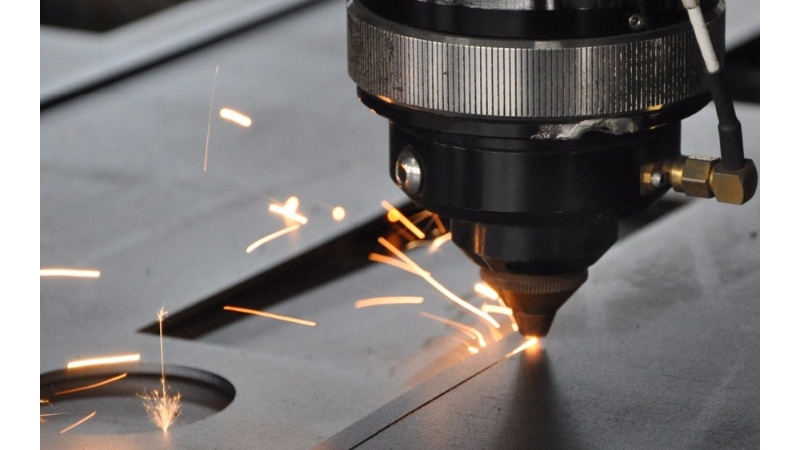

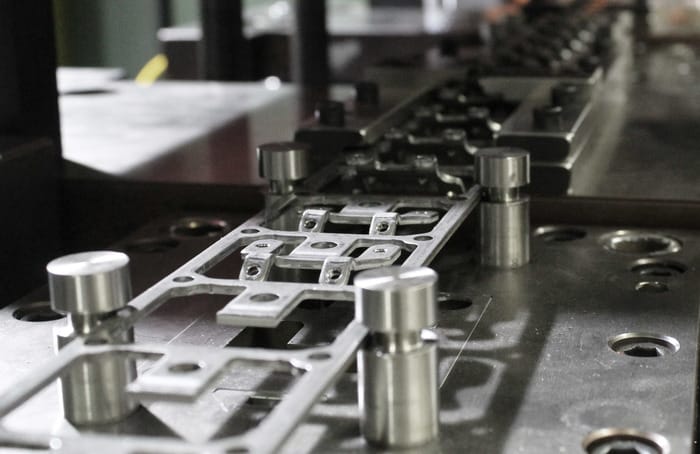

Before diving into the benefits of retrofitting, it’s crucial to understand what stamping presses are. These machines are vital in the manufacturing sector, used to shape or cut metal sheets into specific forms. They’re foundational in producing components for automobiles, electronics, and more.

Components of a Stamping Press

A typical stamping press comprises several key components: the frame, bed, ram, and bolster plate. Each plays a vital role in ensuring the machine operates efficiently. Over time, these components can wear out, leading to decreased performance.

Why Consider Retrofitting?

Retrofitting offers a cost-effective alternative to purchasing new machinery. By upgrading existing equipment, manufacturers can enjoy the benefits of modern technology without the hefty price tag. Additionally, retrofitting can lead to improved safety features, enhanced precision, and increased output.

Cost Savings

Investing in new stamping presses can be a significant financial burden. However, by opting for retrofitting, companies can save up to 50% of the cost compared to buying new equipment. This approach allows businesses to allocate resources more efficiently, ensuring funds are available for other critical areas.

Improved Performance

Modernizing older machines can lead to enhanced performance. With advancements in technology, retrofitted presses can achieve greater precision, faster cycle times, and reduced downtime. This not only boosts productivity but also ensures the production of high-quality components consistently.

Steps in Retrofitting Stamping Presses

Assessment and Planning

The first step in the retrofitting process is a thorough assessment of the existing machinery. This involves evaluating the condition of the press, identifying areas for improvement, and developing a detailed retrofitting plan. Manufacturers can seek guidance from experts to ensure the plan aligns with their specific needs.

Implementation

Once the plan is in place, the next phase involves the actual retrofitting. This can include replacing worn-out components, integrating new technology, and optimizing the machine’s operational parameters. It’s essential to work with experienced technicians to ensure a seamless transition.

Testing and Validation

After retrofitting, rigorous testing is conducted to validate the machine’s performance. This ensures that all upgrades function as intended and that the press meets industry standards. Regular maintenance checks are also crucial to prolong the machine’s lifespan and maintain optimal performance.

Benefits of Retrofitting

Extended Machine Lifespan

One of the primary benefits of retrofitting is the extended lifespan of the machinery. By addressing wear and tear issues and integrating modern components, manufacturers can ensure their presses remain operational for years to come.

Environmental Impact

By choosing to retrofit rather than replace, companies contribute to environmental sustainability. Retrofitting reduces waste and the demand for new resources, aligning with global efforts to minimize industrial carbon footprints.

Challenges in Retrofitting

Technical Expertise

While retrofitting offers numerous benefits, it also presents challenges. One of the main hurdles is the need for technical expertise. Ensuring that the retrofitting process is executed correctly requires skilled technicians familiar with both old and new technologies.

Downtime

During the retrofitting process, machines may need to be taken offline. This can lead to temporary production halts. However, with proper planning and scheduling, downtime can be minimized, ensuring minimal disruption to operations.

Key Considerations

Choosing the Right Partner

When considering retrofitting, selecting the right partner is crucial. Manufacturers should seek companies with a proven track record in retrofitting stamping presses. This ensures that the process is executed efficiently and effectively.

Future-Proofing

Another essential consideration is future-proofing. By integrating scalable solutions and anticipating future technological advancements, manufacturers can ensure their machinery remains relevant and competitive in the long run.

Case Studies

Automotive Industry

In the automotive sector, retrofitting has led to significant improvements in production efficiency. Companies have reported reduced cycle times and enhanced component quality, leading to increased customer satisfaction.

Consumer Electronics

For manufacturers in the consumer electronics industry, retrofitting has enabled the production of more precise components. This has resulted in products that are not only more efficient but also more reliable, enhancing the brand’s reputation.

Conclusion

In conclusion, retrofitting stamping presses offers a viable solution for manufacturers looking to enhance efficiency and reduce costs. By understanding the process and its benefits, companies can make informed decisions that align with their operational goals. As the manufacturing landscape continues to evolve, embracing retrofitting can position businesses for long-term success.

For more insights on enhancing productivity in stamping press operations, you can visit Productivity Improvement.

Frequently Asked Questions

What is the primary benefit of retrofitting stamping presses?

The primary benefit is cost savings. Retrofitting can enhance machine performance at a fraction of the cost of purchasing new equipment.

How long does the retrofitting process take?

The duration varies depending on the complexity of the retrofitting. However, with proper planning, downtime can be minimized.

Is retrofitting suitable for all stamping presses?

While retrofitting offers numerous benefits, it’s essential to assess each machine’s condition to determine its suitability for retrofitting.

This article contains affiliate links. We may earn a commission at no extra cost to you.