In the realm of industrial manufacturing, the quest to enhance productivity while minimizing waste is a never-ending journey. One of the critical areas where manufacturers can make a significant impact is in reducing scrap in metal stamping. Scrap not only increases production costs but also affects the sustainability of manufacturing processes. Therefore, finding strategies to minimize scrap is of paramount importance.

In this article, we will delve into the various techniques and strategies that can be employed to effectively reduce scrap in metal stamping. By understanding and implementing these approaches, manufacturers can achieve higher efficiency and sustainability in their operations.

Understanding Metal Stamping

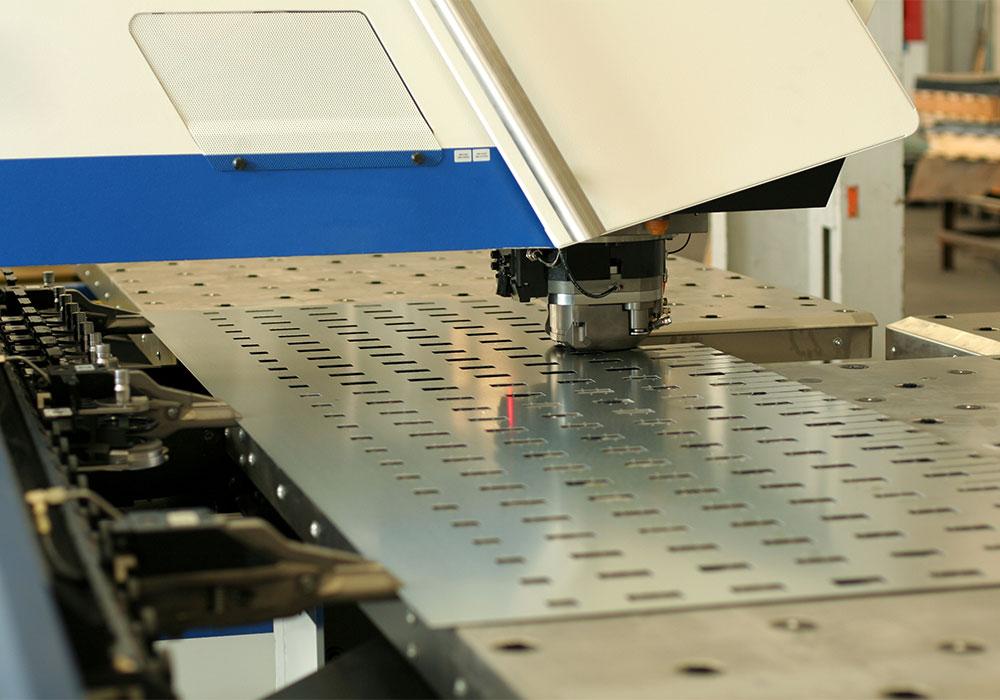

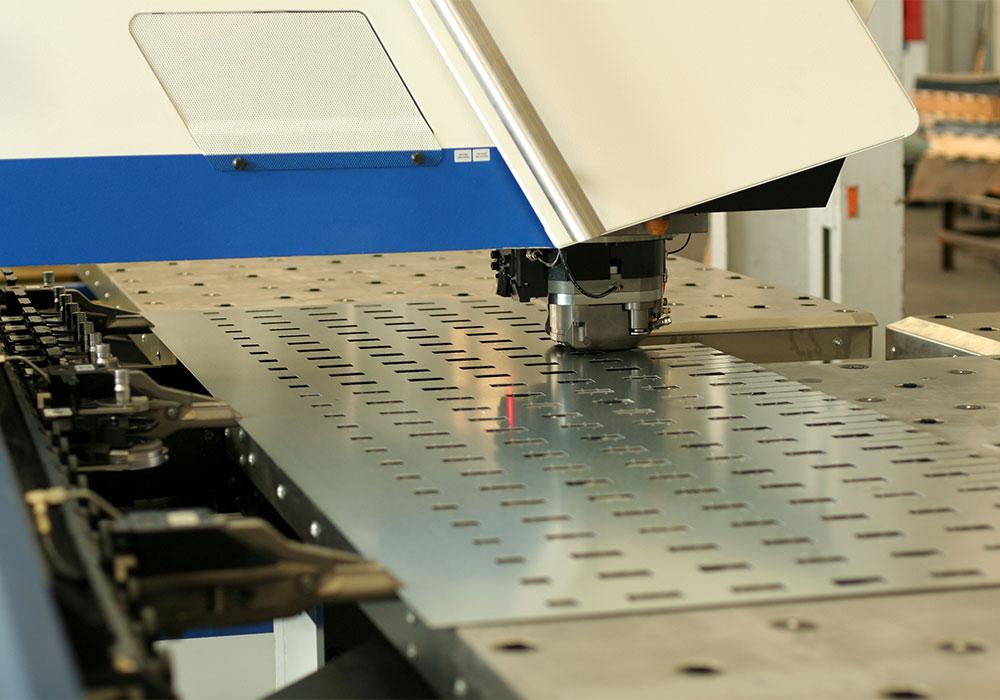

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. This process involves a range of techniques such as punching, bending, and coining to achieve the desired form. Metal stamping is widely used in industries such as automotive, electronics, and appliances due to its ability to produce high volumes of parts consistently.

The Importance of Scrap Reduction

Scrap generated during the metal stamping process can have significant financial and environmental repercussions. It leads to increased material costs, waste disposal expenses, and a larger carbon footprint. Therefore, reducing scrap is not only economically beneficial but also aligns with sustainable manufacturing practices.

Common Causes of Scrap in Metal Stamping

Understanding the root causes of scrap is crucial in devising effective reduction strategies. Some common causes include:

- Material Defects: Poor-quality materials can lead to defects and increased scrap rates.

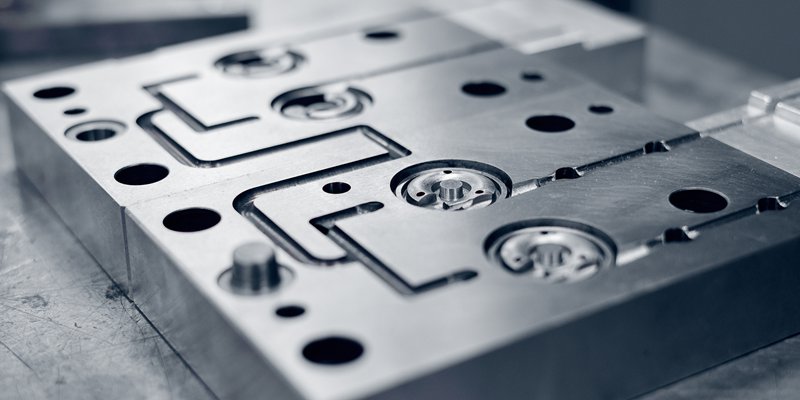

- Tooling Issues: Worn or improperly designed tools can result in inaccurate cuts and bends.

- Improper Setup: Incorrect machine setup and alignment can cause misfeeds and misalignments.

- Operator Error: Lack of training or attention to detail can contribute to scrap generation.

Strategies for Reducing Scrap in Metal Stamping

1. Quality Control Measures

Implementing robust quality control measures is essential to identify and rectify defects early in the production process. Regular inspection of materials and finished products can help minimize scrap.

2. Tool Maintenance and Design

Ensuring that stamping tools are well-maintained and properly designed can significantly reduce scrap. Regular tool inspections and timely replacements can prevent inaccuracies in the stamping process.

3. Optimizing Material Usage

Efficient material utilization is crucial in reducing scrap. This can be achieved through techniques such as nesting, which involves arranging parts on the metal sheet to minimize waste. Additionally, selecting the appropriate material thickness can also contribute to reduced scrap.

4. Employee Training

Training operators on best practices and the importance of scrap reduction can lead to more accurate and efficient production processes. Skilled operators are less likely to make errors that result in scrap.

5. Process Automation

Automating certain aspects of the metal stamping process can enhance precision and consistency, minimizing human error and reducing scrap. Automated systems can ensure accurate part positioning and alignment, leading to improved outcomes.

Case Studies: Success Stories in Scrap Reduction

Several manufacturers have successfully implemented scrap reduction strategies in their stamping operations. For example, an automotive parts manufacturer adopted advanced quality control systems and achieved a 30% reduction in scrap rates within a year.

Implementing Continuous Improvement

Continuous improvement is a key principle in reducing scrap. By regularly reviewing processes, identifying areas for enhancement, and implementing changes, manufacturers can achieve sustained reductions in scrap over time.

The Role of Technology in Scrap Reduction

Advancements in technology have paved the way for more efficient metal stamping processes. The integration of data analytics and real-time monitoring systems allows manufacturers to identify patterns and trends, enabling proactive measures to reduce scrap.

Future Trends in Scrap Reduction

The future of scrap reduction in metal stamping is promising, with emerging technologies such as artificial intelligence and machine learning set to revolutionize the industry. These technologies can optimize processes, predict defects, and further enhance efficiency.

Conclusion

In conclusion, reducing scrap in metal stamping is a critical aspect of achieving efficient and sustainable manufacturing processes. By implementing quality control measures, optimizing material usage, and embracing technological advancements, manufacturers can significantly reduce scrap rates and enhance overall productivity. To learn more about metal stamping, visit Wikipedia’s page on metal stamping.

Frequently Asked Questions (FAQ)

1. What is the main cause of scrap in metal stamping?

The main cause of scrap in metal stamping is often attributed to material defects, tooling issues, improper setup, and operator error.

2. How can technology help in reducing scrap?

Technology can help reduce scrap by providing data analytics, real-time monitoring, and automated systems that enhance precision and consistency in the stamping process.

3. Why is reducing scrap important for manufacturers?

Reducing scrap is important as it leads to cost savings, environmental benefits, and improved sustainability of manufacturing processes.

This article contains affiliate links. We may earn a commission at no extra cost to you.