The modern manufacturing landscape is continually evolving, with industrial manufacturers seeking innovative solutions to boost efficiency and reduce unnecessary costs. A significant challenge in this sector is reducing downtime in stamping operations. This article explores various strategies to minimize downtime, enhancing productivity and profitability.

Understanding Stamping Operations

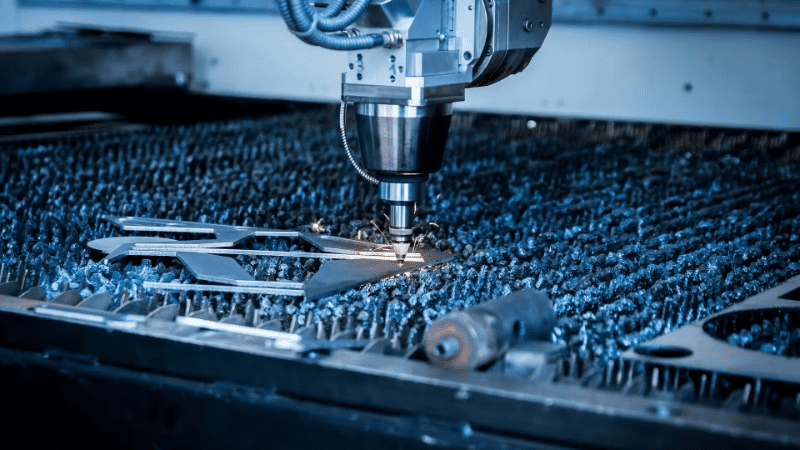

Stamping operations are essential in the manufacturing industry, particularly for producing metal components. These operations involve shaping or cutting metal using a press machine. However, like any other machinery, stamping presses are susceptible to downtime, which can severely impact production timelines and costs.

Why Downtime Occurs in Stamping Operations

Downtime in stamping operations can occur due to various reasons, including mechanical failures, maintenance issues, and human errors. Understanding these causes is the first step towards identifying effective solutions for reducing downtime.

Key Strategies for Reducing Downtime

1. Regular Maintenance and Inspections

Routine maintenance and inspections play a crucial role in ensuring the smooth operation of stamping machines. By identifying potential issues before they escalate, manufacturers can prevent unexpected breakdowns that lead to downtime.

2. Implementing Advanced Monitoring Systems

Advanced monitoring systems provide real-time data on machine performance, helping operators detect anomalies early. For more insights, explore our article on stamping press monitoring.

3. Investing in Employee Training

Well-trained employees can significantly reduce operational errors that contribute to downtime. Regular training programs ensure that staff are knowledgeable about the latest technologies and best practices in stamping operations.

4. Utilizing High-Quality Equipment

Investing in high-quality, reliable equipment is vital. While initial costs may be higher, the long-term benefits include reduced downtime and maintenance expenses. Consider the debate between used vs new stamping equipment to make informed decisions.

5. Adopt Preventive Maintenance Strategies

Preventive maintenance involves regular servicing and replacement of parts before they fail. This proactive approach helps in maintaining continuous operations and reduces the likelihood of unexpected machine failures.

6. Embrace Technological Innovations

Technological advancements such as the integration of IoT devices can provide valuable insights into machine health and performance. These innovations enable manufacturers to adopt predictive maintenance strategies effectively.

7. Efficient Production Planning

Effective production planning minimizes downtime by ensuring that resources are optimally utilized. This includes scheduling maintenance during off-peak hours to avoid disruptions in production.

8. Conducting Regular Vibration Analysis

Vibration analysis helps in detecting misalignments and other mechanical issues early. To learn more about this process, read our detailed post on vibration analysis.

9. Streamlining Communication

Improved communication between different departments ensures that any issues are addressed promptly, reducing delays and enhancing overall efficiency.

10. Optimize Tooling and Die Changes

Efficient tooling and die changes can significantly reduce downtime. Implementing quick-change systems can help streamline these processes.

The Role of External Expertise

Engaging external experts can provide valuable insights and recommendations for optimizing stamping operations. These experts bring a fresh perspective and can identify areas for improvement that may not be apparent to internal staff.

Conclusion

Reducing downtime in stamping operations is critical for enhancing productivity and maintaining a competitive edge in the manufacturing industry. By implementing the strategies outlined above, manufacturers can minimize disruptions, increase efficiency, and ultimately improve their bottom line.

FAQs

1. What are the common causes of downtime in stamping operations?

Common causes include mechanical failures, lack of maintenance, and operational errors. Implementing preventive and predictive maintenance strategies can help address these issues.

2. How can technology help in reducing downtime?

Technology, such as IoT devices and advanced monitoring systems, provides real-time data on machine performance, enabling early detection of potential issues and facilitating predictive maintenance.

3. Why is employee training important in reducing downtime?

Well-trained employees are less likely to make operational errors, ensuring smoother and more efficient operations. Regular training also keeps staff updated on the latest industry practices and technologies.

For more detailed information on how stamping machines work, visit this external resource.

This article contains affiliate links. We may earn a commission at no extra cost to you.