The realm of quality control in stamping production is pivotal for ensuring the reliability and efficiency of manufacturing processes. In the industrial world, maintaining high standards of quality is not merely a goal but a necessity. This article delves into the essential practices and methodologies involved in quality control, providing industrial manufacturers with comprehensive insights into enhancing their stamping production processes.

Understanding Stamping Production

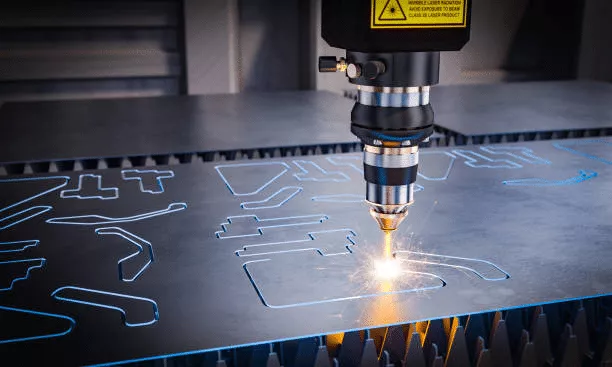

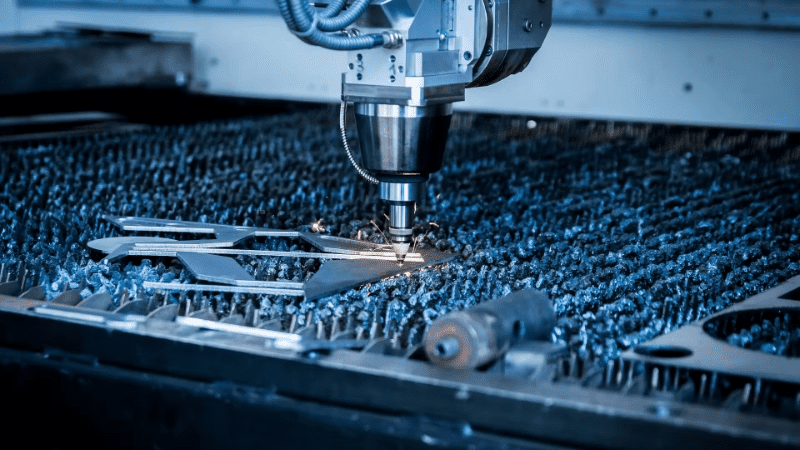

Stamping production is a metalworking process that involves the use of dies to transform flat metal sheets into specific shapes. This process is vital in the production of a variety of components used in industries ranging from automotive to electronics. Given its importance, quality control becomes a critical aspect to ensure precision and consistency in the final products.

The Importance of Quality Control in Stamping

Quality control in stamping production is essential for minimizing defects and ensuring that products meet specified standards. It involves a series of checks and balances, including inspections and testing, to identify and rectify issues early in the production process. This proactive approach not only reduces waste but also enhances customer satisfaction by delivering high-quality products consistently.

Key Elements of Quality Control

- Inspection: Regular inspections are conducted to ensure that the production process adheres to predefined standards.

- Testing: Testing of materials and products is crucial to identify any deviations from the desired quality.

- Statistical Process Control (SPC): SPC involves the use of statistical methods to monitor and control the production process.

Strategies for Effective Quality Control

Implementing effective quality control strategies requires a systematic approach. Here are some strategies that industrial manufacturers can adopt:

1. Implementing Advanced Technologies

The integration of advanced technologies, such as automation and AI, can significantly enhance the accuracy and efficiency of quality control processes. These technologies enable real-time monitoring and analysis, ensuring that any discrepancies are promptly addressed.

2. Training and Development

Investing in the training and development of the workforce is crucial for maintaining high standards of quality. Skilled employees are better equipped to identify potential issues and implement corrective measures effectively.

3. Continuous Improvement

Adopting a culture of continuous improvement is vital for staying competitive in the manufacturing industry. Regular reviews and updates to quality control processes ensure that they remain relevant and effective.

Challenges in Quality Control

While quality control in stamping production is essential, it is not without its challenges. Some of the common challenges include:

- Complexity of Processes: The complexity of stamping processes can make it difficult to identify and address quality issues.

- Cost Constraints: Implementing comprehensive quality control measures can be costly, posing a challenge for manufacturers with limited budgets.

- Regulatory Compliance: Ensuring compliance with industry regulations adds an additional layer of complexity to quality control efforts.

Overcoming Challenges

Despite these challenges, manufacturers can adopt several strategies to overcome them:

1. Leveraging Data Analytics

Data analytics can provide valuable insights into production processes, helping manufacturers identify patterns and trends that may indicate quality issues.

2. Collaborative Approach

A collaborative approach involving all stakeholders can enhance the effectiveness of quality control efforts. This includes engaging suppliers, employees, and customers in the quality control process.

3. Investing in Research and Development

Investing in research and development can lead to the development of innovative solutions that address quality control challenges effectively.

Future Trends in Quality Control

The future of quality control in stamping production is likely to be influenced by several emerging trends:

1. Increased Use of Automation

Automation is expected to play a more significant role in quality control, enabling more efficient and accurate processes.

2. Integration of IoT

The Internet of Things (IoT) is likely to facilitate real-time monitoring and control of production processes, enhancing quality control efforts.

3. Focus on Sustainability

Sustainability is becoming increasingly important in the manufacturing industry, and quality control processes will need to adapt to this trend.

Conclusion

Quality control in stamping production is a critical component of industrial manufacturing, ensuring that products meet high standards of quality and reliability. By implementing effective strategies and embracing emerging technologies, manufacturers can enhance their quality control efforts, overcoming challenges and staying competitive in the industry.

FAQs

- What is stamping production? Stamping production is a metalworking process that involves the use of dies to transform flat metal sheets into specific shapes.

- Why is quality control important in stamping production? Quality control is essential to ensure that products meet specified standards, minimizing defects and enhancing customer satisfaction.

- What are some common challenges in quality control? Common challenges include the complexity of processes, cost constraints, and regulatory compliance.

For more information on metal stamping, you can visit this external resource.

Additionally, explore topics such as Garden Art and Repurposed Saw Blades for innovative ideas in metalworks.

This article contains affiliate links. We may earn a commission at no extra cost to you.