In the world of industrial manufacturing, understanding the intricacies of progressive die strip layout design is crucial. This design process is at the heart of efficient metal stamping, a method widely used in producing components for various industries. By optimizing this design, manufacturers can significantly enhance their production efficiency and reduce costs. Let’s delve deeper into the essential aspects of this vital process.

Introduction to Progressive Die

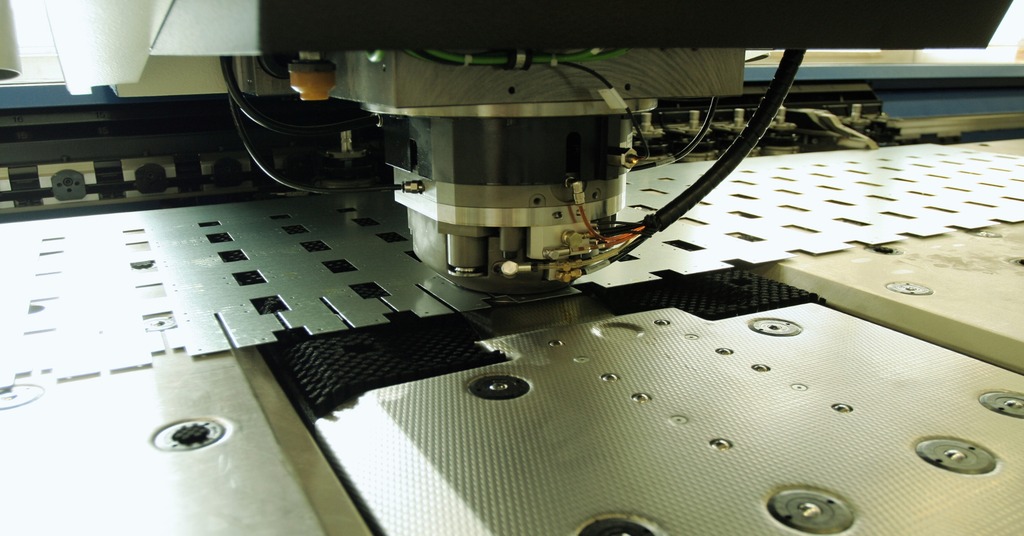

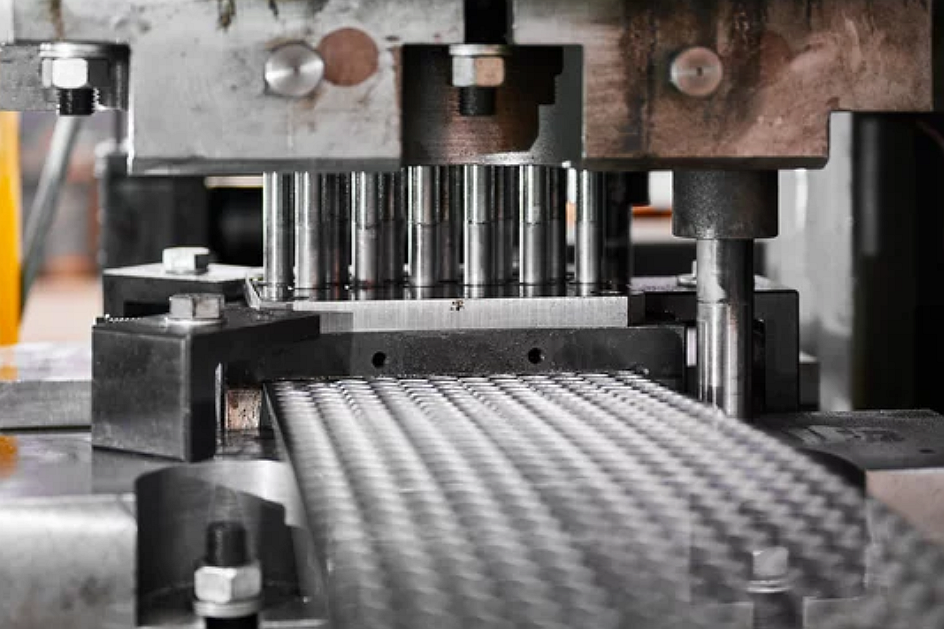

A progressive die is a tool used in metal stamping that performs multiple operations in a series of steps. Each step in the process progressively forms the metal until the final shape is achieved. This system is highly efficient, allowing for the rapid production of complex parts.

Importance of Strip Layout Design

The strip layout design in progressive die is a blueprint that determines how the metal strip will be processed through the die. It dictates the sequence of operations and ensures that each stage of the process is optimized for speed and precision. Proper design minimizes waste and maximizes material usage, which is crucial for maintaining cost-effectiveness in manufacturing.

Key Elements of Strip Layout Design

- Material Utilization: Ensuring the design maximizes the use of raw materials.

- Process Sequencing: Arranging operations in the most logical and efficient order.

- Die Life: Designing for durability to extend the life of the die.

Steps in Designing a Progressive Die Strip Layout

Designing a progressive die strip layout involves several critical steps:

1. Initial Conceptualization

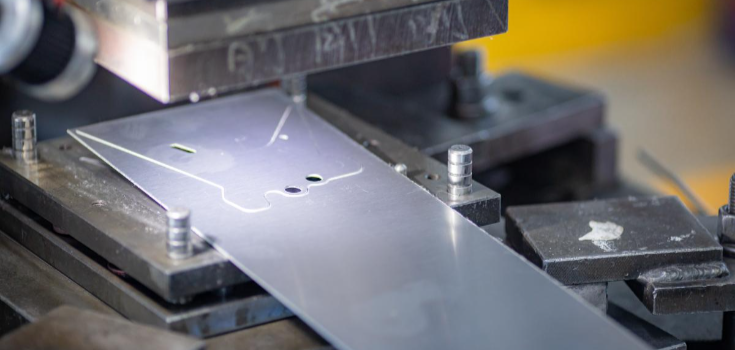

In this phase, the basic idea of the part to be produced is developed. Designers consider the dimensions, material type, and intended application of the final product.

2. Material Selection

Choosing the right material is vital. The material must be suitable for the intended application and compatible with the stamping process.

3. Process Planning

This involves determining the sequence of operations. Each stage of the die needs to be planned to ensure smooth transition from one operation to the next.

4. Design Optimization

Optimization involves tweaking the design to enhance efficiency and reduce waste. Designers use software tools to simulate the stamping process and identify potential issues.

Benefits of Effective Strip Layout Design

An effective strip layout design offers numerous benefits:

- Increased Efficiency: Streamlining operations leads to faster production cycles.

- Cost Reduction: Efficient design minimizes material waste and reduces operational costs.

- Quality Improvement: A well-designed layout ensures consistent product quality.

Challenges in Progressive Die Strip Layout Design

Despite its benefits, designing a progressive die strip layout comes with challenges:

Complexity of Design

The design must accommodate various operations while maintaining efficiency, which can be complex.

Material Limitations

Different materials behave differently during stamping, and not all are suitable for every design.

Technological Advancements

Keeping up with advances in technology and integrating them into the design process can be daunting.

Technological Tools for Design Improvement

Modern technology offers tools to aid in the design process:

Computer-Aided Design (CAD)

CAD software allows designers to create detailed models of the strip layout, facilitating precise planning and adjustments.

Finite Element Analysis (FEA)

FEA helps in predicting how materials will react under various conditions, aiding in optimizing the design.

Simulation Software

Simulations can test the entire stamping process virtually, identifying potential issues before actual production begins.

Impact of Stamping Press Productivity

The design of the progressive die strip layout has a direct impact on stamping press productivity. A well-designed layout can enhance productivity by ensuring smooth operations and reducing downtime.

Future Trends in Progressive Die Design

As technology evolves, so does the field of progressive die design. Future trends include the integration of monitoring systems to provide real-time data and feedback, enhancing the precision and efficiency of the stamping process.

Conclusion

Understanding and implementing efficient progressive die strip layout design is essential for industrial manufacturers looking to enhance their production capabilities. By embracing technological advancements and focusing on key design principles, manufacturers can achieve significant improvements in efficiency and cost-effectiveness.

FAQs

What is a progressive die?

A progressive die is a tool used in metal stamping that performs multiple operations on a metal strip in a series of steps, ultimately forming the desired part.

Why is strip layout design important?

Strip layout design is crucial because it determines the sequence of operations in stamping, optimizing material usage, and ensuring efficient production.

How does technology aid in progressive die design?

Technology, such as CAD and simulation software, aids in designing precise models, optimizing the stamping process, and identifying potential issues before production.

For more detailed insights on metal stamping processes, you can visit Rapid Direct’s comprehensive guide on the topic.

This article contains affiliate links. We may earn a commission at no extra cost to you.