Metal stamping is a crucial process in the manufacturing industry, and understanding the progressive die design basics is essential for any industrial manufacturer. This article will delve into the intricacies of progressive die design, highlighting its significance, components, and applications. Whether you are new to this field or looking to enhance your knowledge, this guide will provide you with valuable insights into the world of progressive die design.

What is Progressive Die Design?

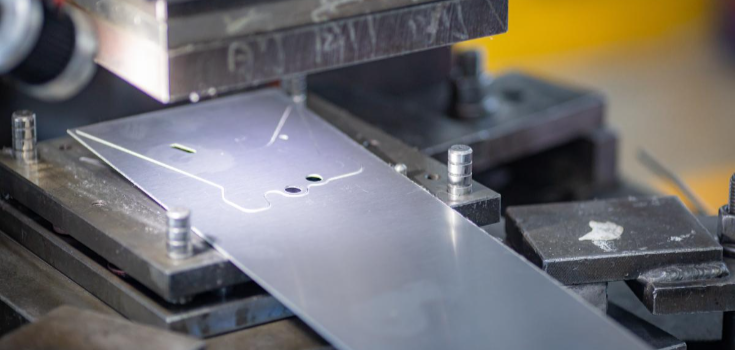

Progressive die design involves creating a specialized tool used in metal stamping operations. It enables the production of complex parts by sequentially performing a series of operations on a strip of metal. Each stage of the die performs a specific task, such as cutting, bending, or drawing, until the final product is achieved. This efficient and cost-effective process is widely employed in industries such as automotive, electronics, and appliances.

The Importance of Progressive Die Design

The significance of progressive die design lies in its ability to streamline production processes and enhance efficiency. By incorporating multiple operations into a single die, manufacturers can reduce production time, minimize material waste, and improve overall productivity. Additionally, progressive die design allows for high precision and consistency, ensuring the production of high-quality components that meet stringent industry standards.

Key Components of Progressive Die Design

Understanding the key components of progressive die design is crucial for effective implementation. Let’s explore these components in detail:

Strip Layout

The strip layout is a critical aspect of progressive die design. It involves determining the optimal arrangement of the part features on the metal strip. By carefully planning the strip layout, manufacturers can maximize material utilization and minimize waste. This step requires a thorough understanding of the part’s dimensions, tolerances, and production requirements.

Die Stations

Die stations are the individual sections within the progressive die that perform specific operations. Each station is designed to execute a particular task, such as punching, bending, or forming. The number and arrangement of die stations depend on the complexity of the part and the desired production output. Proper sequencing of die stations is crucial to ensure smooth material flow and efficient production.

Stripper Plate

The stripper plate is an essential component of progressive die design. It holds the metal strip in place during the stamping process and prevents any movement or distortion. The stripper plate also assists in ejecting the finished part from the die. Its design and alignment play a vital role in maintaining accurate part dimensions and minimizing defects.

Pilot Pins

Pilot pins are used to guide the metal strip through the die stations accurately. They ensure precise alignment and positioning, preventing any misalignment or shifting during the stamping process. Properly designed and positioned pilot pins contribute to the overall accuracy and quality of the stamped parts.

Applications of Progressive Die Design

Progressive die design finds applications in various industries, offering numerous benefits and advantages. Let’s explore some of the key areas where this design approach is widely utilized:

Automotive Industry

In the automotive industry, progressive die design plays a vital role in the production of complex components such as brackets, connectors, and structural parts. The ability to perform multiple operations in a single die ensures high precision and consistency, meeting the stringent quality requirements of the automotive sector. To learn more about the importance of quality in metal art for the automotive industry, you can visit this link.

Electronics Industry

In the electronics industry, where miniaturization and intricate designs are prevalent, progressive die design enables the efficient production of components such as connectors, terminals, and lead frames. The high precision and repeatability of this design approach ensure the reliability and performance of electronic devices. For DIY enthusiasts interested in laser-cut metal art projects, you can explore this link.

Appliance Industry

The appliance industry relies on progressive die design for the production of parts such as brackets, hinges, and panels. The ability to incorporate multiple operations into a single die reduces production costs and improves overall efficiency. This design approach ensures the consistent production of high-quality components that meet the demanding requirements of the appliance industry. Discover more about metal mosaic garden projects in this link.

Benefits of Progressive Die Design

The adoption of progressive die design offers numerous benefits to manufacturers, enhancing their production capabilities and competitiveness. Let’s explore some of the key advantages:

Increased Efficiency

By combining multiple operations into a single die, manufacturers can significantly reduce production time and increase efficiency. The streamlined process eliminates the need for separate setups and reduces downtime, resulting in higher productivity and cost savings.

Cost Savings

Progressive die design minimizes material waste by optimizing the strip layout and maximizing material utilization. The efficient use of resources translates into cost savings for manufacturers, making it an economically viable solution for high-volume production.

Improved Quality

The precise and consistent nature of progressive die design ensures the production of high-quality components with tight tolerances. The elimination of manual handling and the automated nature of the process contribute to minimizing defects and improving overall product quality.

Challenges in Progressive Die Design

While progressive die design offers numerous advantages, it also presents certain challenges that manufacturers need to address. Let’s explore some of the common challenges faced in this design approach:

Complexity of Design

The design and development of progressive dies require a high level of expertise and technical knowledge. The complexity of the design process, including strip layout, die station sequencing, and component integration, demands careful planning and attention to detail.

Tooling Costs

The initial investment in tooling for progressive die design can be significant. The design and fabrication of the die, along with the customization required for specific applications, contribute to the overall tooling costs. However, the long-term benefits and cost savings often outweigh the initial investment.

Maintenance and Troubleshooting

Maintaining and troubleshooting progressive dies can be challenging due to their complex nature. Regular maintenance and inspection are essential to ensure optimal performance and prevent any potential issues that may arise during production. Skilled personnel and proper training are crucial for effective maintenance and troubleshooting.

Conclusion

In conclusion, understanding the progressive die design basics is essential for industrial manufacturers aiming to optimize their production processes. This design approach offers numerous benefits, including increased efficiency, cost savings, and improved quality. While challenges exist, proper planning, expertise, and maintenance can overcome them. By embracing progressive die design, manufacturers can stay competitive in the ever-evolving manufacturing industry.

Frequently Asked Questions (FAQs)

What are the advantages of progressive die design?

Progressive die design offers increased efficiency, cost savings, and improved quality. By combining multiple operations into a single die, manufacturers can reduce production time and optimize resource utilization.

What industries benefit from progressive die design?

Progressive die design is widely used in industries such as automotive, electronics, and appliances. These industries benefit from the high precision, consistency, and cost-effectiveness offered by this design approach.

What are the challenges in progressive die design?

The challenges in progressive die design include the complexity of design, tooling costs, and maintenance requirements. However, with proper planning and expertise, these challenges can be effectively addressed.

This article contains affiliate links. We may earn a commission at no extra cost to you.