When it comes to metal fabrication, understanding the press brake vs stamping press differences is crucial for Industrial Manufacturers. Both press brakes and stamping presses are essential tools in the industry, but they serve different purposes and have distinct functionalities. In this article, we’ll delve into these differences, helping you make informed decisions for your manufacturing needs.

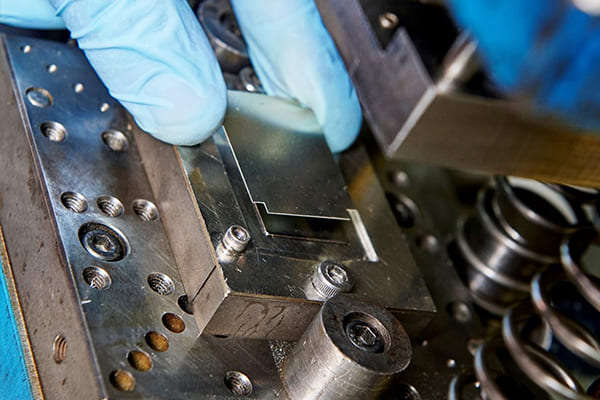

What is a Press Brake?

A press brake is a machine used for bending sheet metal into various shapes. It operates by clamping the metal between a punch and die. The process is precise, allowing for the creation of complex bends and angles. Press brakes are known for their versatility, making them a staple in many fabrication shops.

How Does a Press Brake Work?

The press brake uses hydraulic or mechanical force to press the punch into the metal, bending it along the die. The operator can adjust the angle and extent of the bend, offering a high degree of control over the final product.

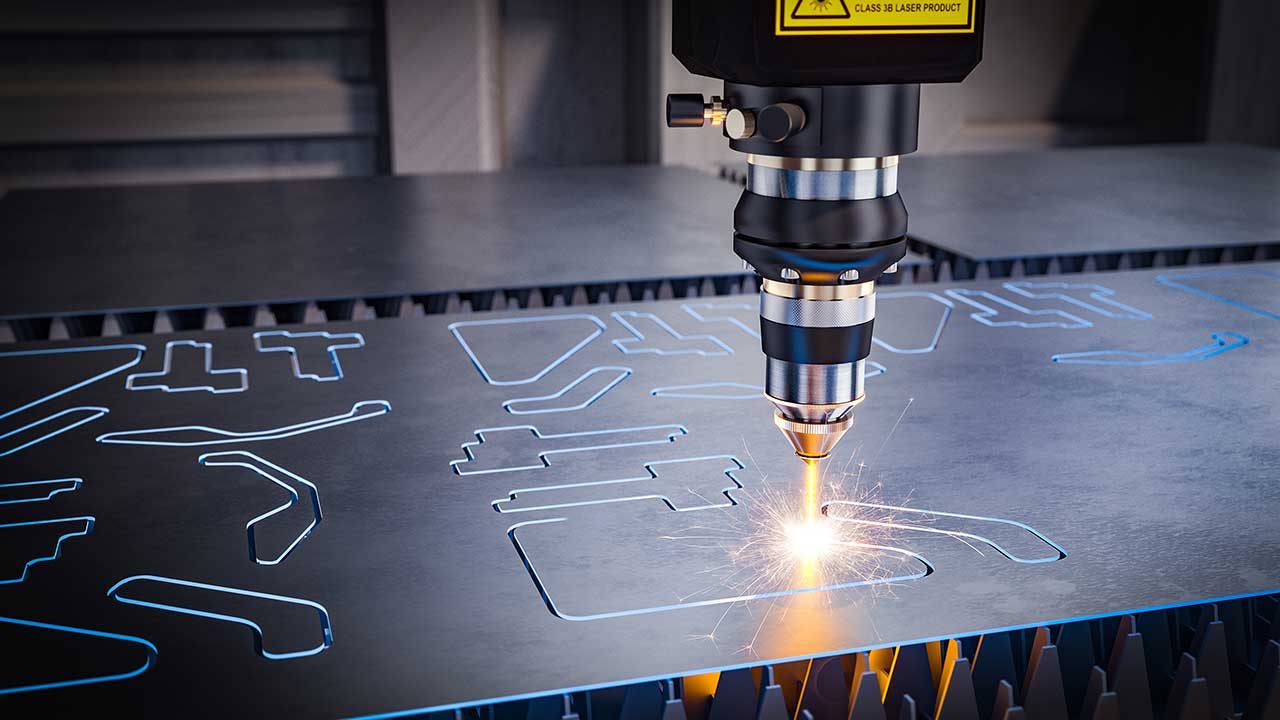

What is a Stamping Press?

A stamping press is used to shape or cut metal by deforming it with a die. This machine is ideal for high-volume production, as it can produce identical parts quickly and efficiently.

How Does a Stamping Press Work?

The stamping press uses a combination of press force and die design to shape the metal. The press can be mechanical or hydraulic, and it operates by moving the die into the metal to cut or shape it.

Key Differences Between Press Brakes and Stamping Presses

The main differences between press brakes and stamping presses lie in their functionality and applications. While press brakes are used for bending and shaping, stamping presses are used for cutting and forming. Another key difference is the production volume; stamping presses are more suitable for large-scale production, whereas press brakes are often used for smaller batches.

Applications of Press Brakes

Press brakes are commonly used in industries where precision bending is required, such as in the production of brackets, frames, and enclosures. Their versatility allows for the creation of a wide range of products without the need for extensive tooling.

Applications of Stamping Presses

Stamping presses are widely used in automotive, aerospace, and consumer electronics manufacturing. They are ideal for producing high volumes of parts, such as metal components for cars or electronic devices. Learn more about stamping press anatomy.

Advantages and Disadvantages

Advantages of Press Brakes

One of the main advantages of press brakes is their precision. They allow for detailed work and can handle a variety of materials and thicknesses. However, they are generally slower than stamping presses and may not be suitable for high-volume production.

Advantages of Stamping Presses

Stamping presses are incredibly efficient for mass production. They can produce a large number of parts in a short time, reducing costs per unit. However, they require specific dies for each part, which can be expensive to produce.

Choosing the Right Tool for Your Needs

When deciding between a press brake and a stamping press, consider your production needs. For complex, low-volume projects, a press brake may be more suitable. For high-volume, less complex parts, a stamping press could be the better choice. Explore our guide on improving stamping press productivity.

Conclusion

Understanding the press brake vs stamping press differences can significantly impact your manufacturing efficiency and cost-effectiveness. By choosing the right tool for your specific needs, you can optimize your production process and achieve better results. For more insights into metalworking, check out our article on used vs new stamping equipment.

FAQs

What is the primary use of a press brake?

A press brake is primarily used for bending and shaping metal sheets into various forms and angles.

Can a stamping press handle different materials?

Yes, a stamping press can handle a wide range of materials, including metals and plastics, depending on the die used.

Which is more cost-effective for large-scale production?

For large-scale production, a stamping press is generally more cost-effective due to its ability to produce high volumes quickly.

This article contains affiliate links. We may earn a commission at no extra cost to you.