In the world of industrial manufacturing, precision stamping equipment plays a pivotal role. It’s crucial for creating high-quality metal components with exact specifications. This article explores the importance, applications, and advancements in this critical technology, providing you with valuable insights into how it can enhance your production processes.

What is Precision Stamping Equipment?

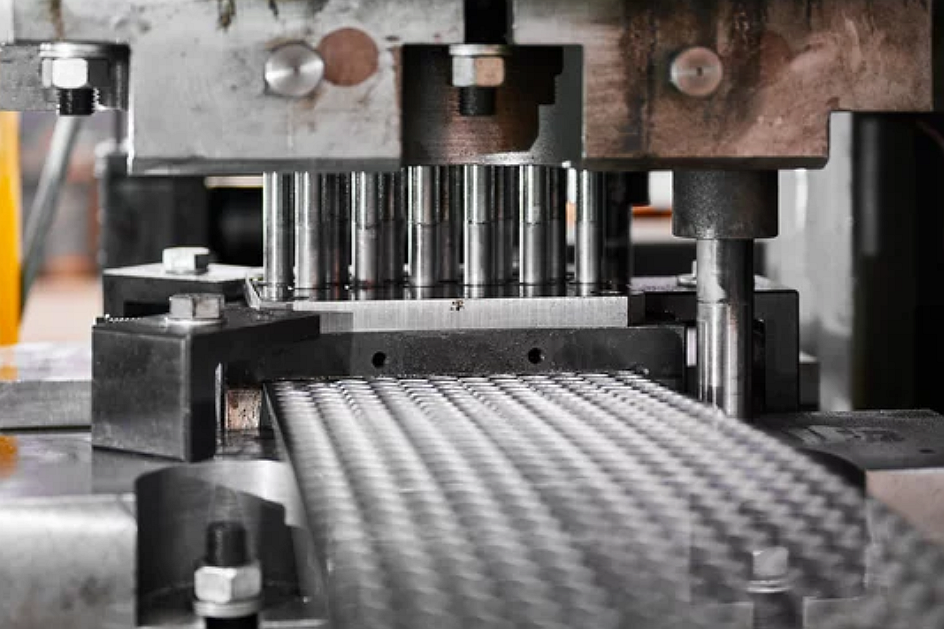

Precision stamping equipment is used to shape and form metal sheets into specific parts and components. This process involves using a stamping press to cut, bend, and shape the material. It’s widely used in various industries, including automotive, aerospace, and electronics, due to its ability to produce intricate and complex parts with high precision and repeatability.

The Importance of Precision Stamping in Manufacturing

For industrial manufacturers, precision stamping equipment is indispensable. It allows for the mass production of parts with minimal waste, ensuring consistent quality and reduced production costs. Moreover, it enables manufacturers to meet tight tolerances and design specifications, which are essential for maintaining the integrity and functionality of the final products.

Applications of Precision Stamping Equipment

Precision stamping equipment finds applications across various sectors. In the automotive industry, it’s used to produce components like engine parts, brackets, and chassis parts. In electronics, it’s essential for creating connectors, switches, and other intricate parts. The aerospace industry relies on precision stamping for producing lightweight, durable components.

Advancements in Precision Stamping Technology

Over the years, advancements in technology have significantly enhanced the capabilities of precision stamping equipment. Modern machines are equipped with computer numerical control (CNC) systems, which improve accuracy and speed. Additionally, advancements in materials and tooling have led to longer tool life and better performance, reducing downtime and increasing efficiency.

The Role of CNC in Precision Stamping

CNC technology has revolutionized precision stamping. By automating the stamping process, CNC systems ensure higher accuracy and consistency, allowing manufacturers to produce complex geometries with ease. This technology also enables quick changeovers and setup times, increasing overall productivity.

Choosing the Right Precision Stamping Equipment

When selecting precision stamping equipment, several factors should be considered. These include the type of material being used, the complexity of the parts, the required production volume, and budget constraints. It’s essential to choose equipment that aligns with your specific production needs to achieve optimal results.

Factors to Consider

- Material type and thickness

- Part complexity and size

- Production volume and cycle times

- Budget and initial investment costs

Manufacturers should also consider the manufacturer’s reputation, after-sales support, and the availability of spare parts when choosing precision stamping equipment.

Maintenance of Precision Stamping Equipment

Regular maintenance is crucial for ensuring the longevity and performance of precision stamping equipment. Routine inspections, lubrication, and timely replacement of worn parts are essential to prevent breakdowns and maintain optimal performance.

Importance of Regular Maintenance

Regular maintenance helps in identifying potential issues before they lead to costly repairs or downtime. It also ensures that the equipment operates at peak efficiency, delivering consistent results and prolonging the lifespan of the machinery.

Future Trends in Precision Stamping

The future of precision stamping looks promising, with ongoing developments in automation, material science, and digital technologies. These advancements are expected to further enhance the efficiency, precision, and versatility of stamping processes, providing manufacturers with new opportunities for innovation and growth.

Automation and AI in Precision Stamping

Automation and artificial intelligence are set to play a significant role in the future of precision stamping. Automated systems will enable real-time monitoring and adjustments, improving quality control and reducing human error. AI-driven analytics will provide insights into production processes, enabling manufacturers to optimize operations and reduce costs.

Conclusion

Precision stamping equipment is a cornerstone of modern industrial manufacturing. Its ability to produce high-quality, intricate parts efficiently makes it an invaluable asset for manufacturers across various sectors. By embracing technological advancements and maintaining their equipment diligently, manufacturers can leverage the full potential of precision stamping to drive innovation and success in their operations.

Frequently Asked Questions

What is the main advantage of using precision stamping equipment?

The main advantage is its ability to produce high-quality, complex parts with minimal waste and high precision, reducing production costs and ensuring consistent product quality.

How does CNC technology enhance precision stamping?

CNC technology automates the stamping process, ensuring higher accuracy and consistency, allowing for the production of complex geometries with ease and increasing overall productivity.

What factors should be considered when choosing precision stamping equipment?

Factors to consider include the type of material, part complexity, production volume, budget, manufacturer’s reputation, after-sales support, and availability of spare parts.

For more detailed information on how stamping presses work, you can visit Press Machine World. Additionally, if you’re interested in exploring unique projects using metal, consider checking out our resources on Metal Mosaic Garden Projects and Quality Metal Garden Art.

This article contains affiliate links. We may earn a commission at no extra cost to you.