Sawing plays a vital role in the world of industrial manufacturing, especially when it comes to producing high-quality components with detailed requirements. The importance of precision sawing techniques cannot be overstated, as they ensure precise cuts, reduced material waste, and improved safety.

The Importance of Precision in Sawing

The concept of precision in sawing refers to the ability to make cuts that are not just accurate in dimensions but also consistent in every piece. This need for precision becomes more crucial when dealing with materials such as metals, plastics, and even specialized woods. By understanding the precise methods, manufacturers can enhance the quality and consistency of their products, improving both efficiency and output quality.

Different Types of Sawing Methods

Band Sawing

Band sawing is one of the most common techniques used in the industrial sector. It involves using a long, sharp blade consisting of a continuous band of toothed metal that moves in a uniform motion. This method is ideal for cutting irregular, curved, and straight shapes.

Circular Sawing

Circular sawing employs a toothed disk or blade that is perfect for making straight, accurate cuts. This technique is often used in the manufacturing of timber and metal products, thanks to its speed and efficiency.

The Tools Behind Precision Sawing

Industrial manufacturers leverage different tools to achieve precision in their sawing operations. Each tool is designed with unique features tailored for specific sawing tasks.

Computer Numerical Control (CNC) Machines

CNC machines have revolutionized the manufacturing industry by providing digital control over sawing operations. These machines guarantee extremely accurate cuts by following pre-programmed designs. They are widely used due to their ability to minimize human errors.

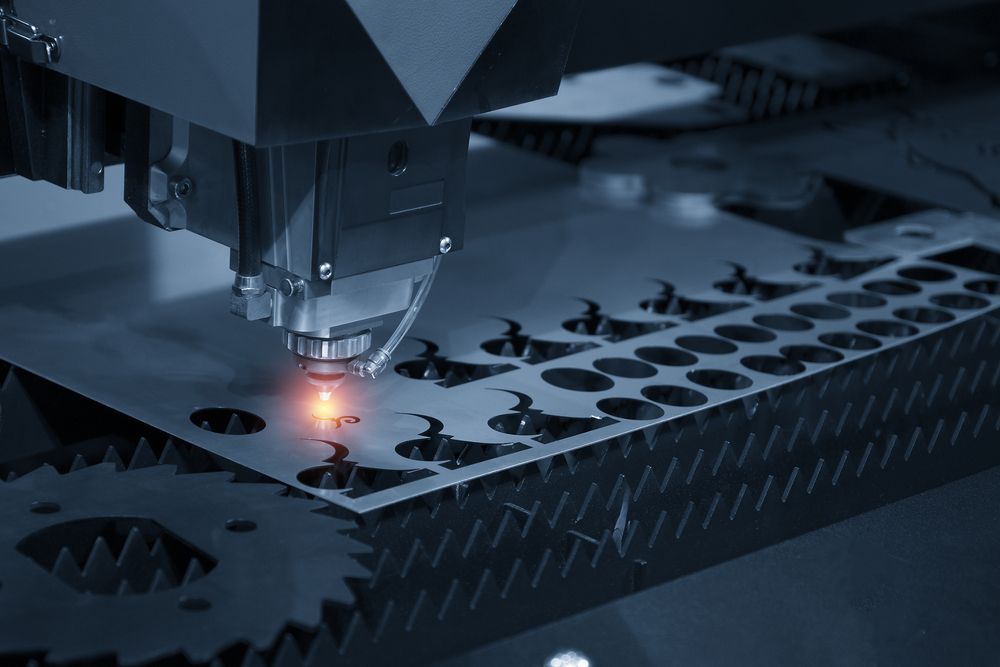

Laser Sawing

Laser sawing uses high-energy beams to achieve precision cuts without making direct contact with the material. This is especially useful for delicate projects requiring minimal disturbance to the material’s structure.

Methods to Enhance Precision

Achieving the highest level of precision requires more than just the right tools. It involves mastering specific techniques that ensure improved accuracy.

Calibration

Regular calibration of equipment ensures that every cut is as accurate as the last. This step cannot be overlooked, as even the best machinery can lose accuracy over time without proper maintenance.

Proper Blade Selection

Choosing the right blade for the material you are working with is crucial. Different blades are designed for different materials, and using the correct one will prevent material wastage and increase accuracy.

Safety Precautions

While mastering precision sawing techniques is important, ensuring safety is equally crucial. Manufacturers must follow essential safety protocols to prevent accidents.

For more safety check tips here

Wear Protective Gear

Wearing the appropriate protective equipment like gloves, glasses, and ear protection can help prevent accidents and damage during sawing operations.

Regular Equipment Maintenance

Frequent checks and maintenance of sawing machinery help in identifying potential hazards and keeping the equipment in optimal working condition.

The Role of Technology in Precision Sawing

The advent of technology has allowed manufacturers to push the boundaries of what is possible in sawing precision. CAM software plays a crucial role.

Digital Precision

Advanced software solutions allow for precise measurements and designs that can be directly fed into cutting machines, eliminating manual errors and improving cut accuracy.

Automation

Automatic saws decrease the manual involvement needed in sawing, reducing human error and increasing consistency across cuts.

The Future of Sawing Techniques

The future of precision sawing lies in the continuous integration of newer technologies, which promises to deliver more accurate, faster, and efficient sawing solutions.

Emerging techniques are embracing innovations that will redefine the manufacturing landscape.

Frequently Asked Questions

What are the benefits of precision sawing techniques?

Precision sawing ensures accurate cuts, reduces waste, and improves material efficiency, which contributes to better product quality and cost savings.

How does technology improve precision in sawing?

Technology, particularly automation and digital controls, enhance precision by minimizing human error while offering unmatched accuracy and consistency in cuts.

Are there different types of precision sawing?

Yes, precision sawing includes various methods such as band sawing, circular sawing, and laser sawing, each having unique advantages depending on the specific requirements.

This article contains affiliate links. We may earn a commission at no extra cost to you.