Precision metal stamping case studies provide valuable insights into the capabilities and advantages of this manufacturing process. Understanding these case studies is essential for industrial manufacturers seeking to optimize their production methods and ensure high-quality outcomes. In this article, we will delve into various case studies that highlight the effectiveness and versatility of precision metal stamping.

Introduction to Precision Metal Stamping

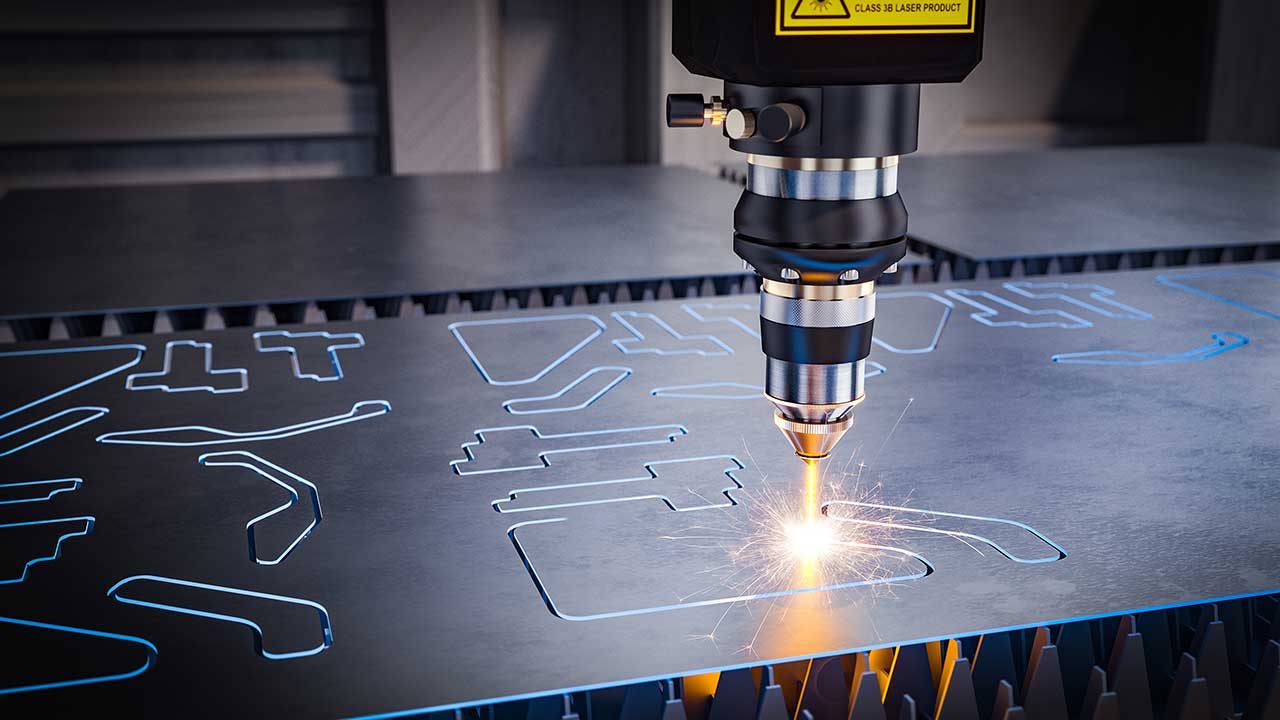

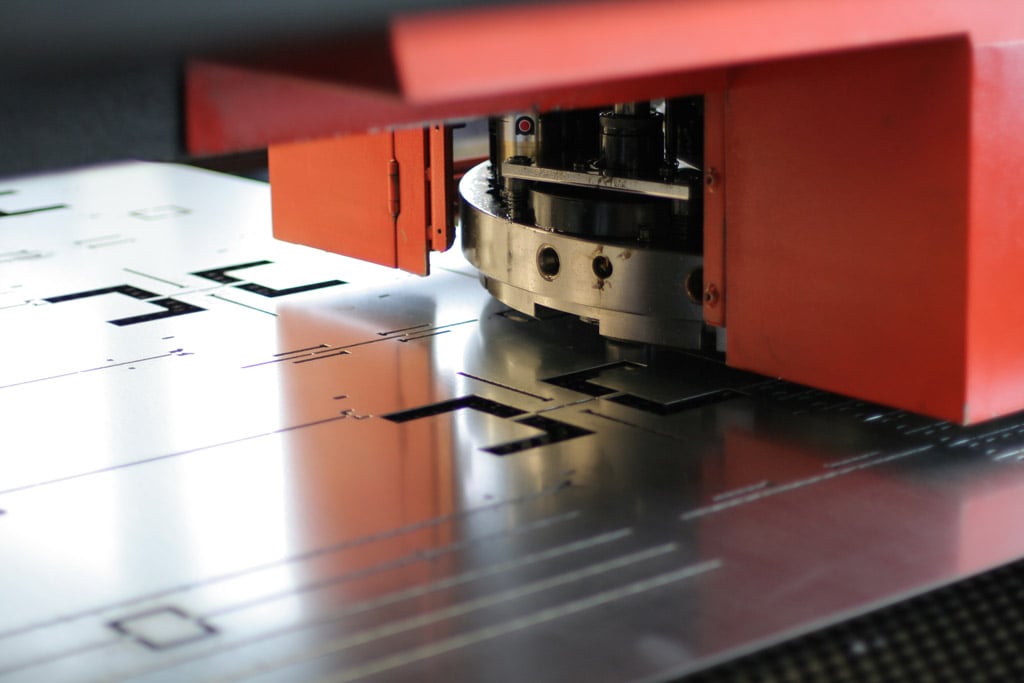

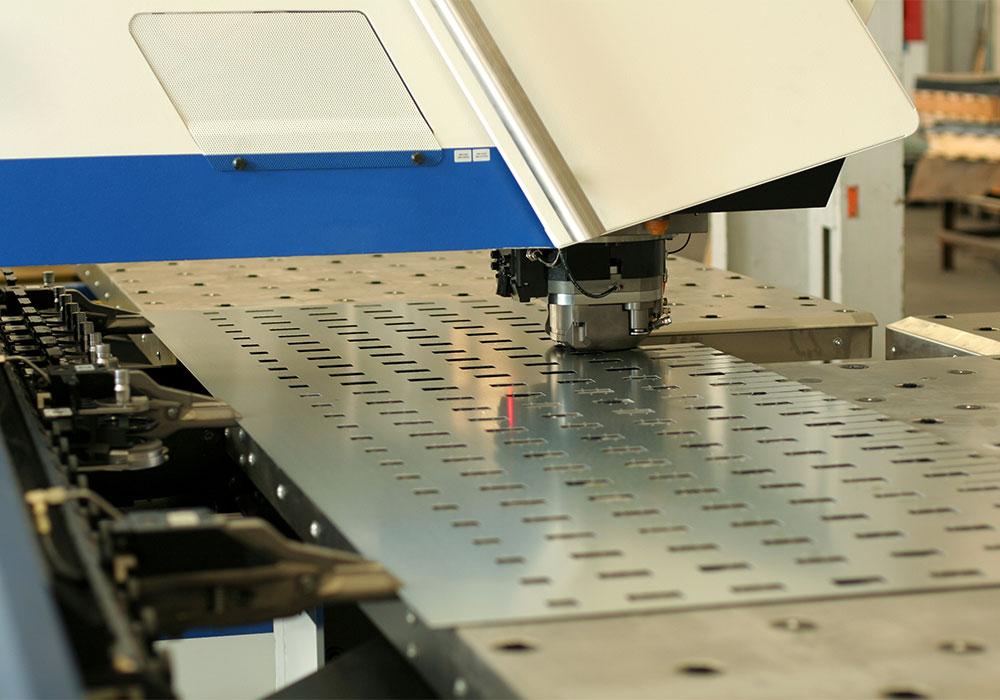

Metal stamping is a crucial process in the manufacturing industry, allowing for the mass production of metal parts with high precision and efficiency. This technique involves the use of a stamping press to shape or cut metal sheets into specific forms. The process is renowned for its ability to produce intricate designs with tight tolerances, making it a preferred choice for many industries, including automotive, aerospace, and electronics.

Advantages of Precision Metal Stamping

One of the primary advantages of precision metal stamping is its cost-effectiveness. The process allows for the production of large quantities of parts with minimal material waste, reducing overall production costs. Moreover, precision metal stamping can achieve high levels of accuracy and repeatability, ensuring consistent quality in each produced part.

Case Study 1: Automotive Industry

In the automotive industry, precision metal stamping plays a vital role in the production of components such as brackets, clips, and fasteners. A notable case study involves a major automotive manufacturer that utilized precision stamping to produce complex parts for their latest vehicle models. By leveraging advanced stamping techniques, the company was able to reduce production time and costs while maintaining the required quality standards.

Case Study 2: Consumer Electronics

In the realm of consumer electronics, precision metal stamping is essential for creating intricate components used in devices like smartphones and laptops. A leading electronics company implemented precision stamping to manufacture micro-sized connectors and enclosures. This approach not only improved the precision of the components but also enhanced the overall product reliability.

Challenges in Precision Metal Stamping

Despite its many advantages, precision metal stamping is not without challenges. Manufacturers often encounter issues related to tool wear, material defects, and process optimization. Addressing these challenges requires a deep understanding of the stamping process and ongoing improvements in technology and materials.

Case Study 3: Aerospace Industry

In the aerospace sector, precision and reliability are paramount. A well-documented case study showcases an aerospace company that faced challenges in producing lightweight yet durable components. By adopting precision metal stamping techniques, the company overcame these challenges, resulting in parts that met strict industry standards while reducing overall weight and enhancing fuel efficiency.

Innovations in Precision Metal Stamping

Recent innovations in the field of precision metal stamping have further expanded its capabilities. Advanced technologies such as computer-aided design (CAD), simulation software, and automation have revolutionized the stamping process, enabling manufacturers to achieve greater levels of precision and efficiency.

Case Study 4: Medical Device Manufacturing

The medical device industry demands components with exceptional precision and quality. A medical device manufacturer utilized precision metal stamping to produce intricate surgical instruments. Through the integration of advanced stamping technology and quality control measures, the company achieved remarkable precision, ensuring the reliability and safety of their products.

Future Trends in Precision Metal Stamping

As technology continues to evolve, the future of precision metal stamping looks promising. The integration of artificial intelligence (AI) and machine learning in the stamping process is expected to enhance process optimization and defect detection. Additionally, the development of new materials and alloys will further expand the possibilities of precision metal stamping.

Case Study 5: Industrial Machinery

In the realm of industrial machinery, precision metal stamping is used to produce components for complex machines and equipment. A case study involving a machinery manufacturer demonstrated the benefits of precision stamping in reducing component weight and enhancing durability, resulting in improved machine performance and longevity.

Conclusion: Embracing Precision Metal Stamping

In conclusion, precision metal stamping case studies highlight the transformative impact of this manufacturing process across various industries. From automotive to aerospace, consumer electronics to medical devices, precision metal stamping offers a cost-effective and efficient solution for producing high-quality components. As technology and innovation drive the industry forward, manufacturers must continue to embrace precision metal stamping to remain competitive in the global market.

For more information on precision metal stamping and its applications, visit National Material.

Frequently Asked Questions

What is precision metal stamping?

Precision metal stamping is a manufacturing process that involves the use of a stamping press to shape or cut metal sheets into specific forms with high precision and efficiency.

How does precision metal stamping benefit manufacturers?

Precision metal stamping offers manufacturers cost-effective production, high accuracy, repeatability, and the ability to produce complex designs with tight tolerances.

What industries utilize precision metal stamping?

Industries such as automotive, aerospace, electronics, and medical device manufacturing frequently utilize precision metal stamping due to its versatility and precision.

This article contains affiliate links. We may earn a commission at no extra cost to you.