In the world of industrial manufacturing, precision grinding in die making is a vital process that ensures the quality and accuracy of components. This technique is indispensable in the creation of dies, which are essential tools in numerous industries. By focusing on precision, manufacturers can produce parts with tight tolerances and intricate details, crucial for industries such as automotive, aerospace, and consumer electronics. Consumer Electronics Stamping often relies heavily on this process.

Understanding Precision Grinding

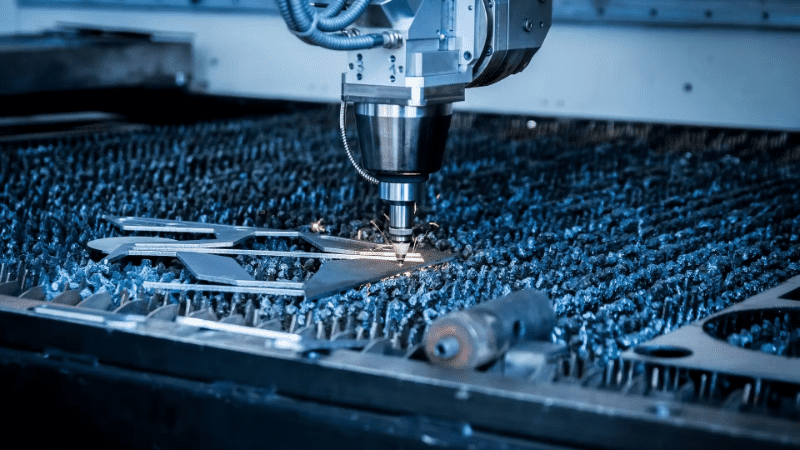

Precision grinding is a process that removes material from a workpiece to achieve exact dimensions and smooth surfaces. This method is often used in the final stages of manufacturing to ensure that parts meet stringent specifications. The process involves the use of specialized grinding machines and abrasive wheels, which are carefully chosen based on the material and desired finish. To learn more about the equipment used, explore New vs Used Equipment.

The Role of Precision Grinding in Die Making

In die making, precision is paramount. Dies are used to shape and cut materials, and any imperfections can lead to significant issues in the final product. Precision grinding helps ensure that dies have the necessary sharpness and durability to perform their functions effectively. This process is particularly important in Medical Device Stamping, where precision and quality are critical.

Types of Precision Grinding Techniques

There are several types of precision grinding techniques used in die making, each suited for different applications:

- Surface Grinding: Used to produce flat surfaces and achieve high surface finish.

- Cylindrical Grinding: Ideal for producing cylindrical shapes and achieving tight tolerances.

- Centerless Grinding: Used for processing long and thin components without the need for centers.

- Internal Grinding: Focused on the inner surface of a hollow object.

Benefits of Precision Grinding in Die Making

The benefits of using precision grinding in die making are numerous. This process allows manufacturers to produce dies that are not only precise but also consistent in quality. It enhances the longevity and reliability of the dies, reducing the risk of defects in the final products. Moreover, it enables manufacturers to meet the high standards required in industries such as Quality Control in Production.

Challenges in Precision Grinding

Despite its benefits, precision grinding presents several challenges. It requires skilled operators and precise machinery. Maintaining the equipment and ensuring consistent quality can be demanding. Training, such as that provided in Operator Training, is essential.

Materials Used in Precision Grinding

The choice of materials is crucial in precision grinding. Common materials include hardened steels, carbides, and ceramics. Each material presents unique challenges and requires specific techniques and tools. Understanding the material properties is essential for achieving the desired results. More insights into materials can be found in this article.

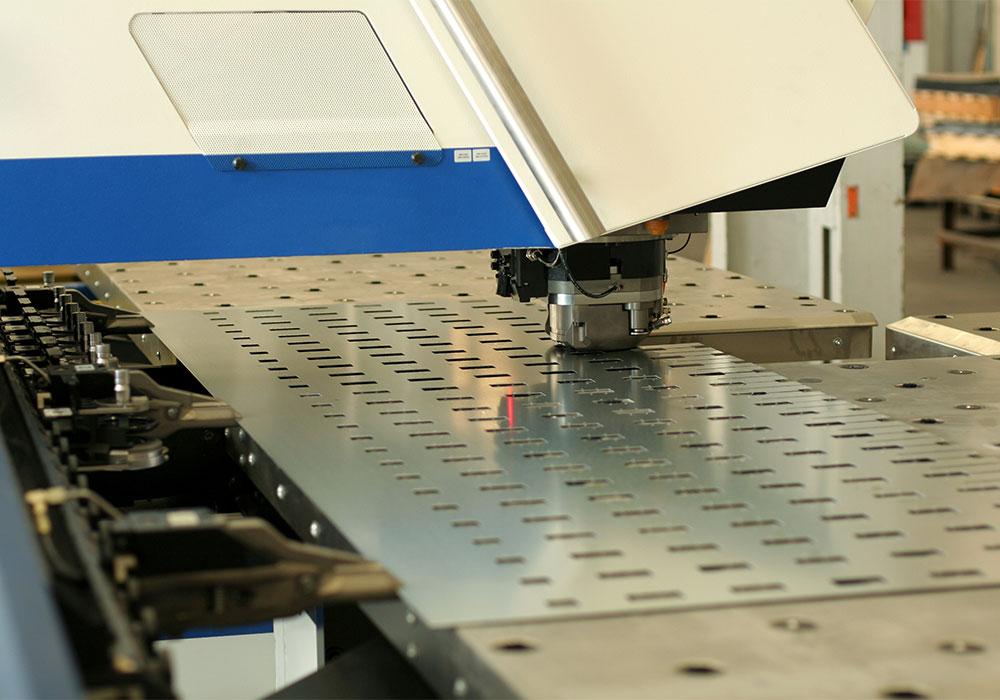

Future Trends in Precision Grinding

As technology advances, new trends in precision grinding are emerging. Automation and smart technology are becoming more prevalent, allowing for greater efficiency and accuracy in the grinding process. These advancements promise to further enhance the capabilities of die making.

Conclusion

Precision grinding in die making is an essential process that plays a critical role in the manufacturing industry. Its importance cannot be overstated, as it ensures the production of high-quality dies that meet the exacting standards of modern industries. By understanding and implementing this technique, manufacturers can achieve superior results and maintain a competitive edge.

Frequently Asked Questions (FAQ)

What is precision grinding?

Precision grinding is a machining process used to remove material from a workpiece to achieve precise dimensions and a high-quality surface finish.

Why is precision grinding important in die making?

Precision grinding ensures that dies have the necessary accuracy and quality to function effectively, reducing the risk of defects in the final product.

What industries benefit from precision grinding in die making?

Industries such as automotive, aerospace, consumer electronics, and medical devices benefit greatly from precision grinding in die making due to the high standards and precision required.

This article contains affiliate links. We may earn a commission at no extra cost to you.