In the fast-paced world of the automotive industry, precision cutting has emerged as a pivotal process that ensures the production of high-quality components. As vehicles evolve to meet increasing consumer demands, the role of precision cutting becomes even more significant. Understanding its importance can offer insights into modern manufacturing techniques that drive the industry forward.

The integration of precision cutting techniques has transformed automotive manufacturing. This process involves exact measurement and cutting of materials to achieve impeccable fittings in various components, from body panels to intricate engine parts.

The Role of Precision Cutting in Automotive Manufacturing

Why Precision is Key

In the automotive sector, precision ensures that all parts fit perfectly without the need for excessive adjustments. This leads to enhanced vehicle performance and longevity. Moreover, precision cutting reduces material wastage, fostering an eco-friendly production cycle.

Technologies Used in Precision Cutting

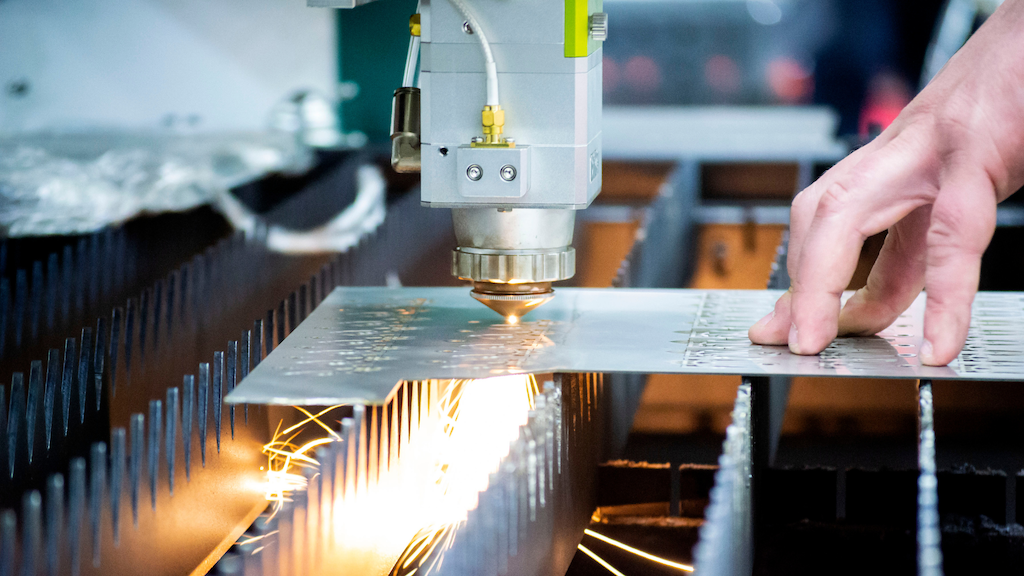

Several technologies contribute to precision cutting. Laser cutting, waterjet cutting, and advanced CNC machinery are among the most popular. These technologies have enabled manufacturers to achieve new levels of accuracy.

For a deeper understanding of how these technologies operate, consider visiting an external resource on metal cutting technologies.

Impact on Quality and Efficiency

Quality Aspects

Through precision cutting, automotive parts meet stringent quality standards which is crucial for vehicle safety and performance. This results in enhanced customer satisfaction and brand reputation for manufacturers.

Efficiency in Production

With automated precision cutting, the production cycle is streamlined. This not only accelerates manufacturing but also significantly cuts down on errors. As a result, vehicles can be assembled faster, reducing time-to-market.

Cutting-edge Techniques in Use

Laser and Waterjet Cutting represent two cutting-edge techniques currently transforming the automotive industry. Laser cutting allows for precision and detail, essential for complex designs and strong materials. Learn more about these methods at modern metalworks waterjet.

On the other hand, waterjet cutting offers versatility, allowing manufacturers to cut through a variety of materials without compromising structural integrity.

CNC Precision

Computer Numerical Control (CNC) machines are indispensable in creating intricate components. These machines utilize computerized systems to guide cutting tools, ensuring precision in every stroke.

Future of Precision Cutting in the Automotive Industry

Trends Shaping the Future

The future of precision cutting in the automotive industry looks promising with advancements in AI and machine learning. These technologies are set to introduce even higher degrees of precision and customization.

Challenges and Opportunities

Despite its advantages, precision cutting faces challenges such as high initial setup costs. However, the long-term benefits in efficiency and quality make it a worthwhile investment.

Conclusion

Embracing precision cutting in the automotive industry is crucial not only for quality and efficiency but also for sustainability. As technology evolves, the capabilities of precision cutting will continue to expand, promising a brighter future for the automotive sector.

FAQs about Precision Cutting in the Automotive Industry

1. What is precision cutting?

Precision cutting is a manufacturing process that uses advanced tools and technologies to cut materials with high accuracy, ensuring parts fit perfectly in assemblies.

2. How does precision cutting improve automotive manufacturing?

It enhances quality, reduces waste, and speeds up production, which are vital for meeting modern manufacturing demands.

3. What technologies are used in precision cutting?

Common technologies include laser cutting, waterjet cutting, and CNC machines, each offering unique benefits for accuracy and efficiency in production.

This article contains affiliate links. We may earn a commission at no extra cost to you.