The world of manufacturing is constantly evolving, with new technologies and methods emerging to improve efficiency, precision, and productivity. Among these advancements, modern stamping press innovations are leading the charge, bringing a fresh wave of change to the industry. Industrial manufacturers are poised to benefit immensely from these developments, as they promise to redefine how metal components are crafted in various sectors.

Modern stamping press innovations are not just about upgrading existing systems but about introducing groundbreaking technologies that make manufacturing more efficient and sustainable. These innovations are making a significant impact across industries, from automotive to electronics, and are expected to shape the future of metalworking. As manufacturers seek to stay competitive in a rapidly changing market, understanding and adopting these advancements has become crucial.

The Evolution of Stamping Press Technology

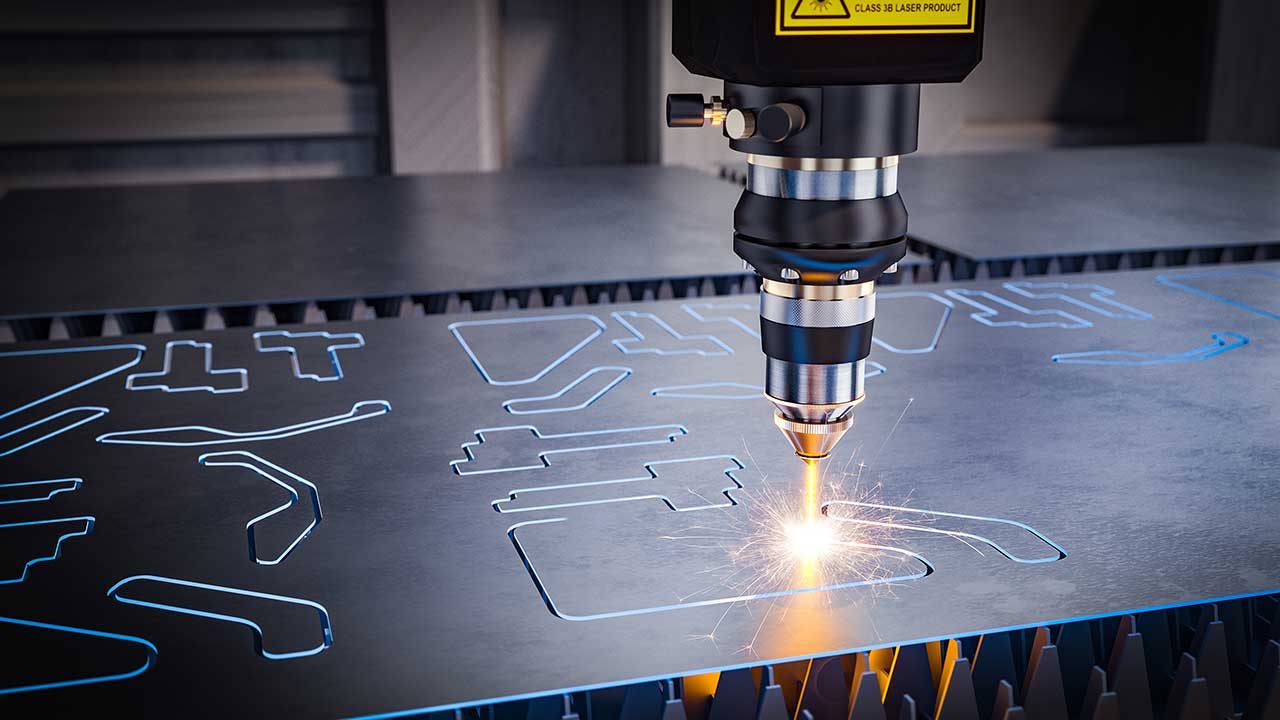

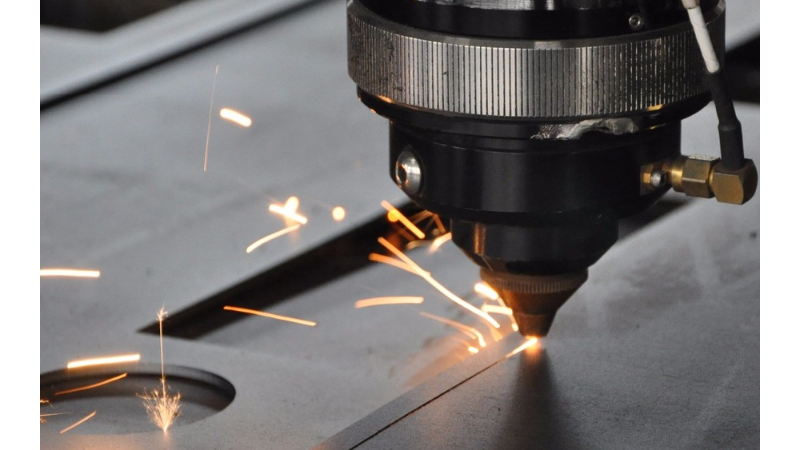

Stamping presses have come a long way since their inception. Initially, they were purely mechanical, relying on manual inputs and basic mechanisms to shape metal. Over time, hydraulic and pneumatic systems were introduced, offering greater force and control. Today, the advent of computer-controlled systems has transformed stamping presses into sophisticated machines capable of performing complex tasks with precision.

From Mechanical to Digital

The shift from mechanical to digital systems marks a significant milestone in stamping press technology. With the integration of computer numerical control (CNC) systems, modern presses can execute complex designs with unparalleled accuracy, reducing waste and increasing efficiency. These systems allow for real-time monitoring and adjustments, ensuring optimal performance and quality output.

Integration of Automation

Automation is another key development in modern stamping press innovations. Automated systems can handle various tasks, from loading and unloading materials to adjusting press parameters. This reduces the need for manual intervention, minimizing human error and increasing production speed. For manufacturers, automation translates to lower costs and higher productivity.

Key Features of Modern Stamping Presses

Advanced Control Systems

Modern stamping presses are equipped with advanced control systems that provide precise control over every aspect of the stamping process. These systems enable manufacturers to fine-tune operations, ensuring consistent quality and reducing downtime.

Customizable Tooling

Customizable tooling is another important feature of contemporary stamping presses. This allows manufacturers to easily switch between different designs and specifications, catering to a diverse range of production needs without significant delays.

Energy Efficiency

With a growing emphasis on sustainability, energy efficiency has become a crucial consideration in manufacturing. Modern stamping presses are designed to consume less energy while maintaining high performance, aligning with environmental goals and reducing operational costs.

Industry Applications

Automotive Sector

In the automotive industry, modern stamping press innovations play a vital role in producing high-precision components that meet stringent safety and performance standards. From body panels to intricate engine parts, stamping presses are indispensable in automotive manufacturing.

Electronics Industry

The electronics sector also benefits significantly from advancements in stamping press technology. Precision is critical in electronic components, and modern presses deliver the accuracy required to produce parts that meet the industry’s demanding specifications.

Aerospace Field

In aerospace, where precision and reliability are paramount, advanced stamping presses are essential for manufacturing components that meet the rigorous standards of the industry. These presses ensure that every piece is crafted to perfection, contributing to the overall safety and performance of aircraft.

Challenges and Solutions

Overcoming Technical Barriers

Despite the numerous advantages, adopting modern stamping press innovations comes with challenges. Technical barriers, such as the need for skilled operators and the integration of new systems, can pose significant hurdles for manufacturers. However, ongoing training and support can help overcome these obstacles.

Cost Considerations

Investing in modern stamping presses requires substantial capital. However, the long-term benefits, including reduced operational costs and increased productivity, often outweigh the initial investment. Manufacturers must carefully assess their financial capacity and potential returns before making the transition.

Adapting to Rapid Changes

The rapid pace of technological change can be daunting for manufacturers. Staying updated with the latest advancements and trends is essential for maintaining a competitive edge. This requires a proactive approach to learning and adapting to new technologies as they emerge.

Future Outlook

The future of modern stamping press innovations looks promising, with continuous advancements expected to further enhance their capabilities. Emerging technologies, such as artificial intelligence and the Internet of Things (IoT), are likely to play a significant role in shaping the future of stamping presses.

AI Integration

Artificial intelligence has the potential to revolutionize stamping press operations by optimizing processes, predicting maintenance needs, and improving overall efficiency. AI-driven systems can analyze data in real-time, providing valuable insights and enabling smarter decision-making.

IoT and Connectivity

The integration of IoT technologies allows stamping presses to communicate with other machines and systems, creating a connected manufacturing environment. This connectivity enhances collaboration and data sharing, leading to improved efficiency and productivity.

Conclusion

In conclusion, modern stamping press innovations are transforming the manufacturing landscape, offering unprecedented opportunities for efficiency, precision, and sustainability. As manufacturers continue to embrace these advancements, the industry is poised for a new era of growth and innovation. For more insights into the mechanics of metal stamping, check out this resource.

FAQs

What are modern stamping press innovations?

Modern stamping press innovations refer to the latest advancements in stamping press technology, including digital controls, automation, and energy-efficient systems, aimed at improving manufacturing processes.

How do these innovations benefit manufacturers?

These innovations enhance efficiency, precision, and productivity, reducing costs and waste. They also enable manufacturers to meet high-quality standards and adapt to changing industry demands.

What challenges do manufacturers face in adopting these technologies?

Challenges include technical barriers, cost considerations, and the need to adapt to rapidly changing technologies. However, with proper training and strategic planning, these challenges can be overcome.

This article contains affiliate links. We may earn a commission at no extra cost to you.