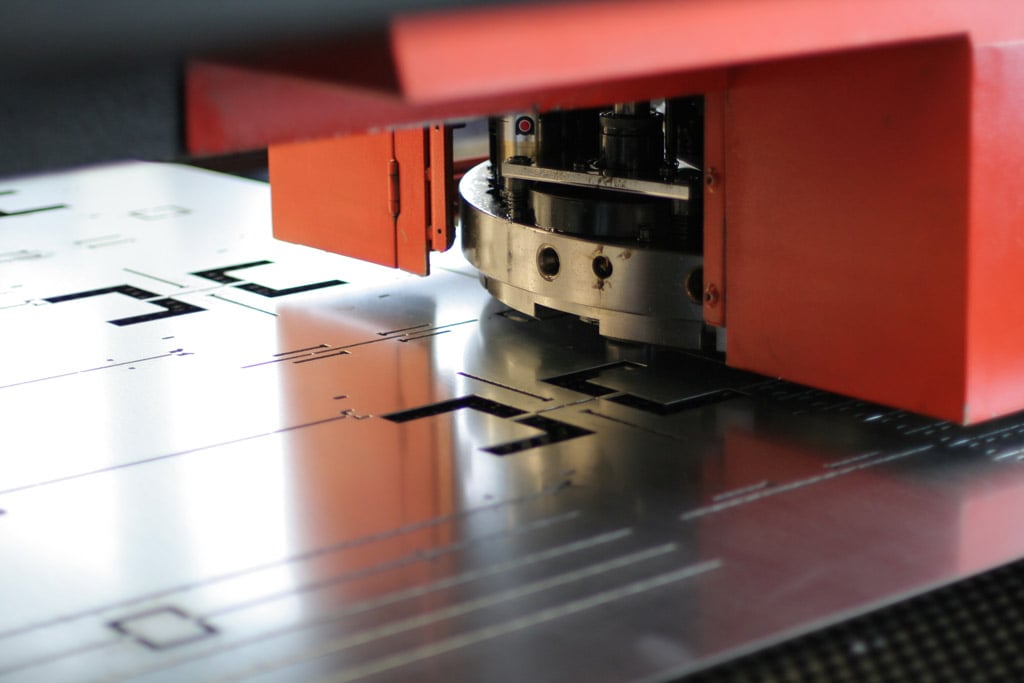

In the ever-evolving world of industrial manufacturing, micro stamping equipment advancements have emerged as a significant area of interest. These advancements are not only reshaping the landscape of manufacturing but also offering new opportunities for efficiency and precision. As manufacturers strive to stay competitive, understanding these changes is crucial.

Micro stamping, a process used to produce small, intricate metal parts, is gaining traction due to its ability to meet the demands of high-precision industries. The latest advancements in micro stamping equipment are setting new standards in accuracy, speed, and cost-effectiveness. This article will delve into these advancements, exploring their impact on the industry and what they mean for manufacturers.

The Evolution of Micro Stamping Equipment

Micro stamping has come a long way since its inception. Initially, the process was limited by the capabilities of the equipment used. However, recent technological innovations have addressed these limitations, leading to more efficient and versatile equipment.

Precision and Accuracy

One of the most notable advancements in micro stamping is the improvement in precision and accuracy. Modern equipment can produce parts with tolerances as small as a few microns, which is essential for industries such as electronics and medical devices.

Speed and Efficiency

Speed is another critical factor in micro stamping equipment advancements. Newer machines are capable of producing parts at a much faster rate, without compromising quality. This increase in speed translates to higher productivity and lower production costs.

Material Versatility

Advancements have also expanded the range of materials that can be used in micro stamping. From traditional metals to advanced alloys and composites, manufacturers now have more options to choose from, allowing for greater customization and innovation.

Impact on Industrial Manufacturing

The impact of these advancements on industrial manufacturing is significant. As equipment becomes more advanced, manufacturers can take advantage of improved efficiency and cost savings. This, in turn, enhances their competitiveness in the global market.

Cost Reduction

By reducing waste and improving efficiency, micro stamping equipment advancements lead to significant cost savings. Companies can produce high-quality parts at a lower cost, which can be passed on to consumers or reinvested in further innovation.

Increased Competitiveness

As manufacturers adopt these advanced technologies, they gain a competitive edge. The ability to produce high-quality parts quickly and efficiently is a significant advantage in a competitive market.

Challenges and Future Trends

Despite the many benefits, there are challenges associated with micro stamping equipment advancements. Manufacturers must invest in training and adaptation to fully leverage the benefits of new technologies.

Training and Skill Development

As technology evolves, so too must the skills of the workforce. Training programs are essential to ensure that employees can operate and maintain new equipment effectively.

Future Innovations

Looking to the future, we can expect continued innovation in micro stamping. Advances in automation, artificial intelligence, and materials science will likely drive further improvements in efficiency and capability.

Conclusion

In conclusion, micro stamping equipment advancements are transforming the industrial manufacturing landscape. By embracing these changes, manufacturers can improve efficiency, reduce costs, and enhance their competitiveness. As technology continues to evolve, the possibilities for innovation in micro stamping are virtually limitless.

For more insights on stamping processes, visit IQS Directory.

FAQs

What is micro stamping?

Micro stamping is a manufacturing process used to create small, precise metal parts. It is commonly used in industries such as electronics and medical devices.

How do advancements in micro stamping equipment benefit manufacturers?

Advancements in micro stamping equipment offer manufacturers improved precision, speed, and cost-effectiveness, leading to higher productivity and competitiveness.

What challenges do manufacturers face with new micro stamping technologies?

Manufacturers may face challenges such as the need for workforce training and adaptation to new technologies. However, the benefits often outweigh these challenges.

To learn more about improving productivity in stamping operations, check out stamping productivity and for insights into vibration analysis, visit vibration analysis.

This article contains affiliate links. We may earn a commission at no extra cost to you.