In the realm of industrial manufacturing, understanding the different metal stamping press types is essential. These presses are pivotal in shaping and cutting metal into desired forms. With numerous types available, selecting the right one can greatly impact production efficiency and product quality. In this article, we’ll delve into the various metal stamping press types, shedding light on their unique features and applications.

Introduction to Metal Stamping

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It’s a crucial technique in industries ranging from automotive to electronics. According to ESICT, the process involves the use of a press to form metal sheets into various parts, which are then used in different products.

Importance of Choosing the Right Press

The choice of metal stamping press types can significantly affect the manufacturing process. The right press ensures precision, efficiency, and cost-effectiveness. Conversely, the wrong choice can lead to increased waste, higher costs, and lower quality products.

Key Factors to Consider

When selecting a press, consider factors like the material thickness, production volume, and the complexity of the design. These factors will guide the decision-making process and ensure optimal outcomes.

Mechanical Presses

Mechanical presses are commonly used in metal stamping. They operate using a motor-driven flywheel that stores energy, which is then transferred to the press ram to perform the stamping operation. Mechanical presses are known for their speed and accuracy, making them ideal for high-volume production.

Applications of Mechanical Presses

These presses are suitable for applications requiring high-speed production, such as in the automotive industry. They are also used in producing small electronic components due to their precision.

Hydraulic Presses

Hydraulic presses utilize a hydraulic cylinder to exert force on the metal. This type of press offers greater flexibility in terms of pressure and dwell time, allowing for more complex stamping operations. They are ideal for applications requiring deep drawing or forming of thicker materials.

Advantages of Hydraulic Presses

Hydraulic presses provide consistent force throughout the stroke, making them suitable for deep drawing processes. They also allow for adjustable speed and pressure, enabling customization for specific tasks.

Screw Presses

Screw presses, also known as fly presses, use a screw mechanism to convert rotational motion into linear motion. These presses are suitable for tasks requiring high precision and moderate force. They are often used in smaller production runs or for intricate designs.

Benefits of Screw Presses

Screw presses offer precision and control, making them ideal for producing small batches or complex designs. They also have a simpler design, leading to lower maintenance requirements.

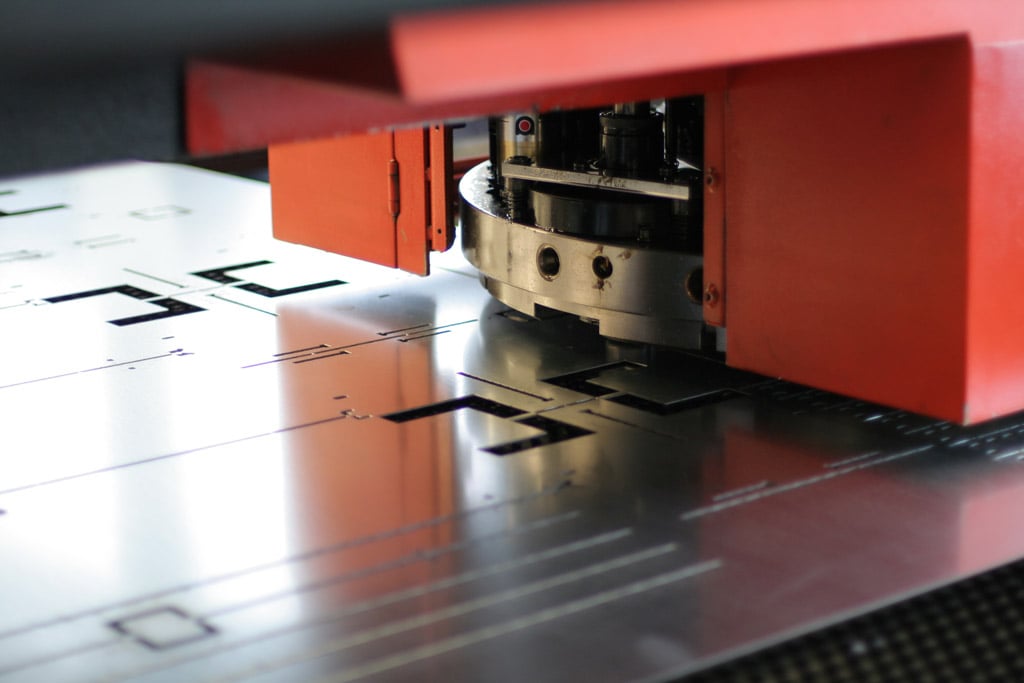

Transfer Presses

Transfer presses are designed for the mass production of parts. They move the workpiece from one station to another, allowing for multiple operations to be performed in a single cycle. This results in higher efficiency and reduced production time.

Applications of Transfer Presses

These presses are widely used in the automotive industry for producing large volumes of identical parts. They are also used in the production of household appliances and electronic components.

Choosing the Right Press for Your Needs

Selecting the appropriate metal stamping press types depends on several factors, including production requirements, material properties, and budget constraints. Consulting with experts and thoroughly evaluating these factors can lead to an informed decision.

Considerations for Selection

When choosing a press, consider the type of material, the complexity of the design, and the production volume. These factors will guide you in selecting a press that meets your specific needs.

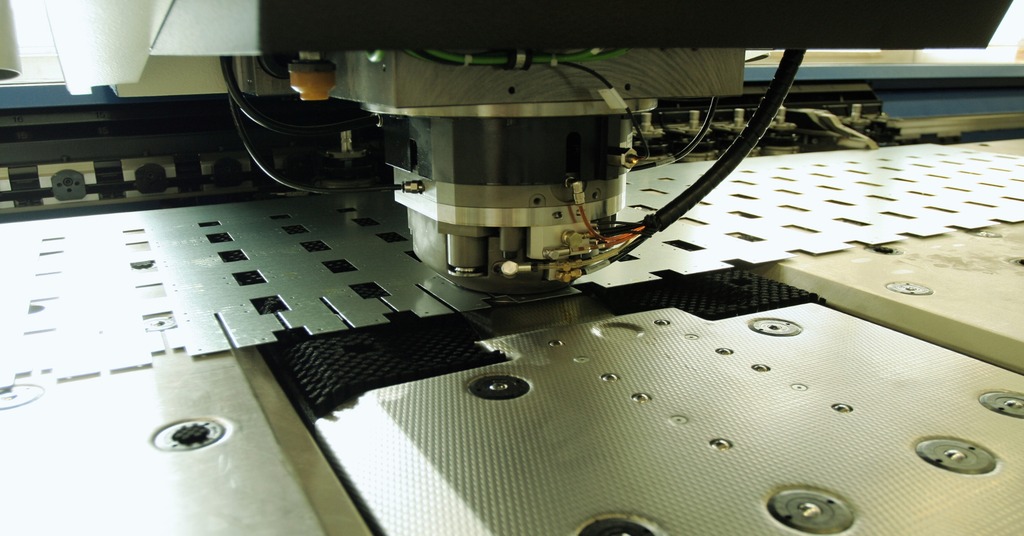

New Technologies in Metal Stamping

Technological advancements have led to the development of presses with enhanced capabilities, such as increased automation, improved precision, and reduced energy consumption. These innovations are shaping the future of metal stamping, making the process more efficient and sustainable.

Impact of Automation

Automation has revolutionized the metal stamping industry, allowing for increased productivity and reduced human error. Automated presses can perform complex tasks with minimal supervision, leading to higher efficiency and lower costs.

Conclusion

Understanding the various metal stamping press types is crucial for optimizing production processes in industrial manufacturing. Each type of press offers unique benefits and is suited for specific applications. By carefully evaluating the needs of your production line, you can select the right press to enhance efficiency and product quality.

FAQs

What are the main types of metal stamping presses?

The main types of metal stamping presses include mechanical presses, hydraulic presses, screw presses, and transfer presses. Each type has its unique features and applications.

How do I choose the right press for my needs?

Choosing the right press involves evaluating factors such as production volume, material properties, and budget. Consulting with experts in the field can also provide valuable insights.

What role does automation play in metal stamping?

Automation plays a significant role in increasing productivity and reducing human error in metal stamping. Automated presses can perform complex tasks with minimal supervision, leading to higher efficiency.

For more information on metal stamping, check out National Material.

This article contains affiliate links. We may earn a commission at no extra cost to you.