The world of metal stamping is vast, intricate, and essential in modern manufacturing processes. Understanding metal stamping inspection techniques is crucial for ensuring the quality, durability, and functionality of stamped products. This article aims to delve into the various methods and practices used in inspecting metal stampings, providing valuable insights for industrial manufacturers.

Introduction to Metal Stamping

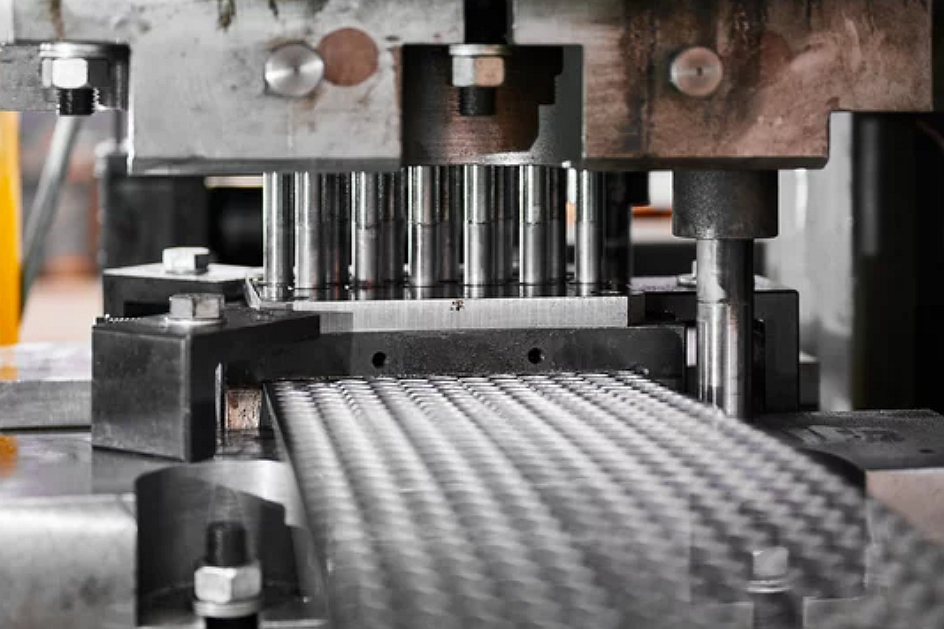

Metal stamping is a manufacturing process that uses dies and high-pressure presses to form metal sheets into specific shapes. It’s a critical process in the production of automotive components, electronics, and appliances. The precision and quality of these components depend significantly on effective inspection techniques.

Importance of Inspection in Metal Stamping

Inspection in metal stamping is vital for maintaining product quality and safety. Defective parts can lead to product failure, safety hazards, and costly recalls. By employing robust inspection techniques, manufacturers can ensure that only high-quality products reach the market.

Types of Metal Stamping Inspection Techniques

There are several inspection techniques used in metal stamping, each with its unique advantages and applications. Let’s explore some of the most common methods.

Visual Inspection

Visual inspection is the most basic form of inspection. It involves examining the stamped parts for visible defects such as cracks, scratches, and deformations. While it is not the most comprehensive method, it is quick and cost-effective.

Dimensional Inspection

This technique measures the physical dimensions of stamped parts to ensure they meet specified tolerances. Tools such as calipers and micrometers are commonly used in this process. Dimensional inspection is crucial for components that require precise measurements.

Non-Destructive Testing (NDT)

NDT techniques allow for the inspection of parts without causing damage. Methods such as ultrasonic testing, radiography, and magnetic particle inspection fall under this category. These techniques are ideal for detecting internal defects that are not visible to the naked eye.

Metallurgical Analysis

Metallurgical analysis involves examining the microstructure of metal parts to detect any irregularities or weaknesses. It provides insights into the material properties and helps identify potential failure points.

Advanced Technologies in Metal Stamping Inspection

With advancements in technology, new inspection methods have emerged, enhancing the accuracy and efficiency of the inspection process.

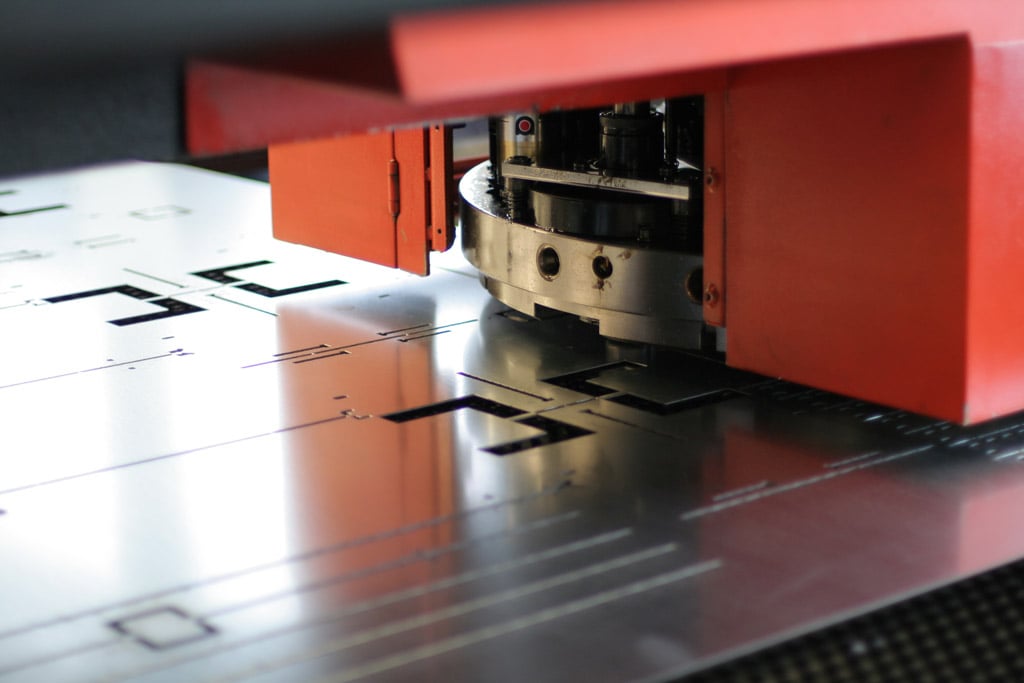

Automated Optical Inspection (AOI)

AOI uses cameras and computer software to automatically inspect metal parts for defects. This technology offers high-speed and high-precision inspection, making it ideal for large-scale production.

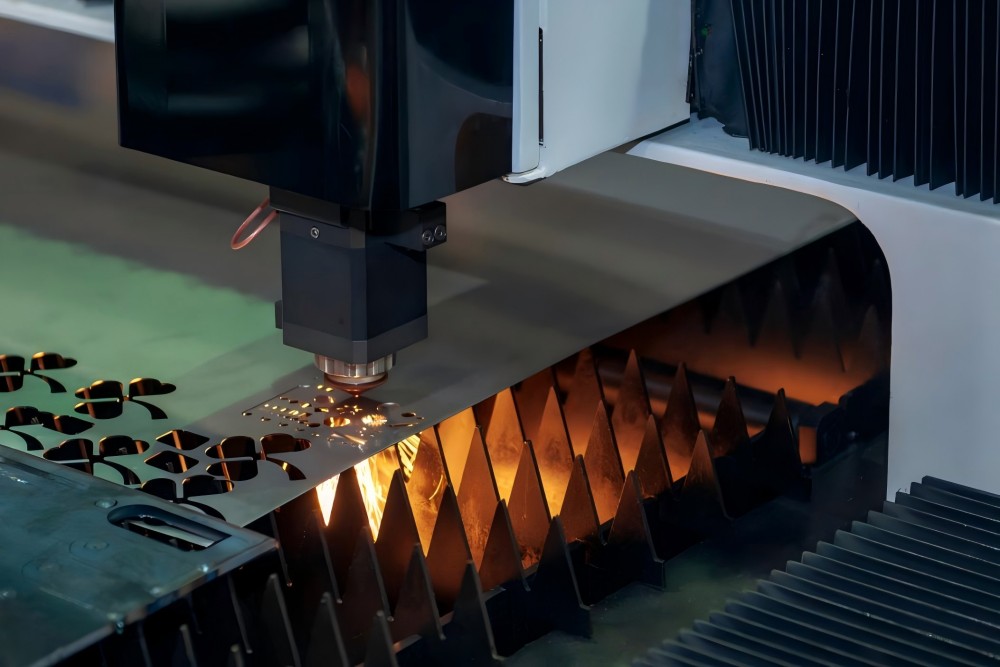

Laser Scanning

Laser scanning is a non-contact method that uses laser beams to capture the dimensions and surface characteristics of metal parts. It provides highly accurate and detailed measurements, making it suitable for complex shapes.

3D Inspection Systems

3D inspection systems use advanced imaging technology to create a three-dimensional model of the stamped part. This allows for precise measurement and analysis of the part’s geometry, helping to identify any deviations from the design specifications.

Challenges in Metal Stamping Inspection

Despite the advancements, there are still challenges in metal stamping inspection. These include the complexity of parts, high production volumes, and the need for specialized equipment and skilled personnel.

Addressing Inspection Challenges

To overcome these challenges, manufacturers can invest in advanced inspection technologies, train personnel, and implement comprehensive quality control systems.

The Role of Quality Control in Metal Stamping

Quality control is integral to the inspection process. It involves setting standards, conducting inspections, and implementing corrective actions to ensure product quality.

Implementing a Quality Control System

A robust quality control system involves defining quality standards, documenting processes, and regularly reviewing and improving inspection methods. It ensures that defects are identified and addressed promptly.

Conclusion

In conclusion, metal stamping inspection techniques are essential for ensuring the quality and reliability of stamped products. By employing a combination of traditional and advanced inspection methods, manufacturers can meet the demands of the market while maintaining high-quality standards.

FAQs

What is the most common inspection technique in metal stamping?

Visual inspection is the most common technique due to its simplicity and cost-effectiveness. However, for more detailed analysis, techniques like dimensional inspection and non-destructive testing are used.

Why is non-destructive testing important?

Non-destructive testing is important because it allows for the detection of internal defects without damaging the part. This ensures that the components meet quality standards without compromising their integrity.

How does laser scanning improve inspection accuracy?

Laser scanning improves accuracy by providing precise measurements and detailed surface data. It captures the exact dimensions and characteristics of complex parts, enabling accurate inspection and quality control.

For more information on metal stamping, you can visit Sangiacomo Presses.

Explore more about metal art and its quality at Metal Garden Art.

This article contains affiliate links. We may earn a commission at no extra cost to you.