The metal stamping for automotive industry is a pivotal process in the manufacturing of vehicles. It involves shaping metal into various forms and components essential for building cars. This method is crucial because it enhances precision, reduces waste, and increases production efficiency. Understanding the nuances of metal stamping can significantly benefit those involved in the automotive sector.

What is Metal Stamping in Automotive?

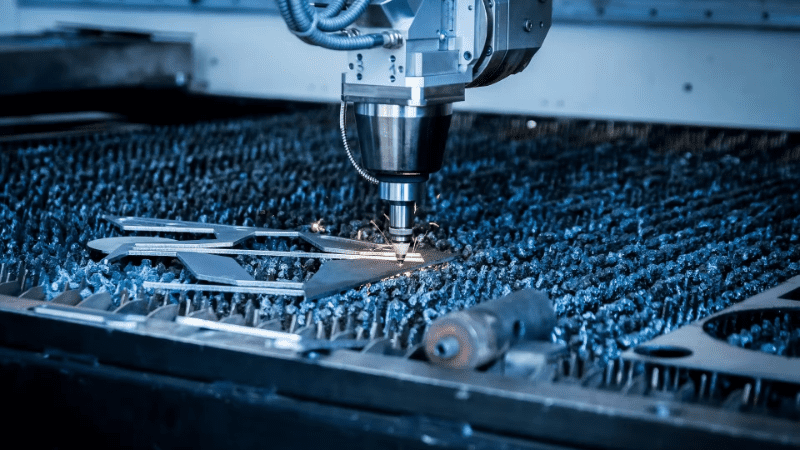

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a critical operation in the automotive industry, where it is used to create parts like panels, brackets, and other components. This process ensures that each piece is produced to exact specifications, maintaining quality and consistency.

The Importance of Metal Stamping in Automotive Manufacturing

In the automotive industry, the demand for high-quality and precise components is ever-growing. Metal stamping plays a vital role in meeting these demands. It allows manufacturers to produce complex parts with high accuracy, which is essential for the performance and safety of vehicles.

Benefits of Metal Stamping in Automotive

Metal stamping offers numerous advantages in automotive manufacturing. These include cost efficiency, high precision, and the ability to produce large volumes quickly. The process minimizes material wastage and ensures that the parts meet stringent quality standards.

Cost Efficiency and Precision

One of the primary benefits of metal stamping is its cost efficiency. By utilizing advanced techniques and machinery, manufacturers can produce parts at a lower cost while maintaining high precision. This efficiency is crucial in the competitive automotive market, where cost control is vital.

Advancements in Metal Stamping Technology

The metal stamping industry is continually evolving, with new technologies enhancing the process. Innovations such as computer-aided design (CAD) and automation have revolutionized metal stamping, making it more accurate and faster. These advancements are essential for meeting the increasing demands of the automotive sector.

Automation and Increased Efficiency

Automation has significantly improved the metal stamping process. Automated machinery can operate with minimal human intervention, increasing efficiency and reducing errors. This technology is particularly beneficial in the automotive industry, where precision and speed are paramount.

Challenges in Metal Stamping for Automotive Industry

Despite its advantages, metal stamping also presents several challenges. These include maintaining quality control, managing the costs of advanced machinery, and ensuring environmental sustainability. Addressing these challenges is essential for the continued success of metal stamping in the automotive industry.

Quality Control and Maintenance

Maintaining high-quality standards in metal stamping is crucial. Manufacturers must implement rigorous quality control measures to ensure that each part meets the required specifications. Regular maintenance of stamping die and equipment is also necessary to prevent defects and ensure longevity. For more insights, check out this Stamping Die Maintenance Guide.

Environmental Considerations in Metal Stamping

The environmental impact of metal stamping is a growing concern. Manufacturers are adopting sustainable practices to minimize waste and reduce their carbon footprint. This shift towards sustainability is vital for the future of the automotive industry.

Reducing Waste and Energy Usage

Sustainable metal stamping practices focus on reducing waste and energy consumption. By using eco-friendly materials and optimizing processes, manufacturers can lessen their environmental impact. This approach not only benefits the planet but also enhances the company’s reputation.

Future of Metal Stamping in the Automotive Industry

The future of metal stamping in the automotive industry looks promising, with continuous advancements in technology and sustainability. As the demand for vehicles grows, so does the need for efficient and precise manufacturing processes like metal stamping.

Trends to Watch

Emerging trends in metal stamping include increased automation, the use of lightweight materials, and the integration of smart technologies. These trends will shape the future of the automotive industry, making it more efficient and sustainable.

Conclusion

In conclusion, metal stamping for automotive industry is an essential process that continues to evolve. With advancements in technology and a focus on sustainability, the future of metal stamping is bright. Manufacturers must stay informed about these trends to remain competitive in the ever-changing automotive landscape.

FAQ

What materials are commonly used in metal stamping?

Common materials include steel, aluminum, and brass. These materials are chosen for their durability and malleability, which are crucial for producing high-quality automotive parts.

How does automation impact metal stamping?

Automation increases efficiency and precision in metal stamping. It allows for faster production times and reduces the likelihood of errors, making the process more cost-effective.

What are the environmental benefits of sustainable metal stamping?

Sustainable metal stamping practices help reduce waste and energy consumption. By adopting eco-friendly methods, manufacturers can decrease their environmental impact and improve their reputation.

For more information about the metal stamping process, visit this Metal Stamping Press 101 guide.

This article contains affiliate links. We may earn a commission at no extra cost to you.