In the world of industrial manufacturing, understanding the intricacies of metal stamping equipment is crucial. This metal stamping equipment guide aims to provide a comprehensive overview for those involved in the manufacturing sector. Whether you’re a seasoned professional or a newcomer, this guide will help you navigate the complexities of metal stamping.

What is Metal Stamping?

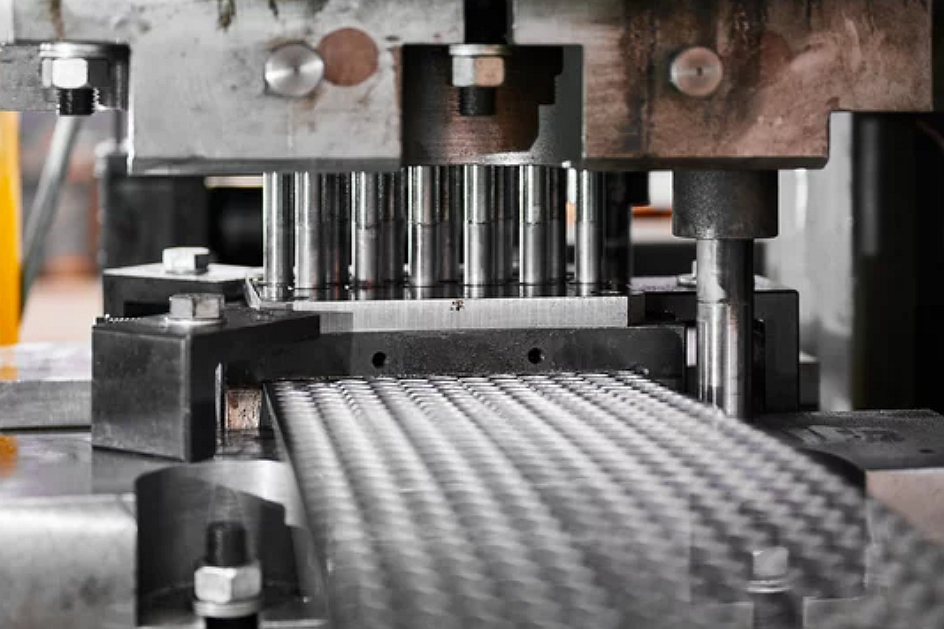

Before diving into the specifics of metal stamping equipment, it’s important to understand what metal stamping is. Metal stamping is a process used to shape metal into specific forms. It involves the use of a stamping press to form metals into desired shapes through cutting, bending, and pressing. This process is widely used in manufacturing industries to produce parts for automobiles, appliances, and more.

The Importance of Metal Stamping

Metal stamping is essential in the manufacturing industry for several reasons. It allows for mass production of intricate metal parts with high precision. This method is cost-effective and efficient, making it a preferred choice for many manufacturers. Stamping also ensures uniformity and consistency in the production process, which is vital for quality control.

Types of Metal Stamping Equipment

Mechanical Presses

Mechanical presses are commonly used in metal stamping. These machines use a flywheel to store energy, which is then transferred to the punch. Mechanical presses are known for their speed and precision, making them ideal for high-volume production.

Hydraulic Presses

Hydraulic presses use a hydraulic cylinder to generate force. They are versatile and can handle a variety of tasks, including deep drawing and blanking. Hydraulic presses are known for their control and accuracy, making them suitable for complex stamping operations.

Servo Presses

Servo presses use a servo motor to drive the press. This type of press offers precise control over the movement of the ram, making it ideal for applications that require high precision.

Choosing the Right Metal Stamping Equipment

When selecting metal stamping equipment, several factors need to be considered. These include the type of metal being used, the complexity of the design, and the production volume. It’s important to choose equipment that can handle the specific requirements of your manufacturing process.

Key Considerations for Metal Stamping

Material Selection

The choice of material plays a crucial role in the stamping process. Metals such as steel, aluminum, and copper are commonly used in stamping. Each material has its own properties and requires different handling techniques.

Tooling Design

Tooling is a critical component of metal stamping. Proper tooling design ensures accuracy and efficiency in the production process. It’s essential to invest in high-quality tooling to achieve the best results.

Quality Control

Maintaining quality control is vital in metal stamping. This involves regular inspections and testing to ensure that the stamped parts meet the required specifications. Implementing a robust quality control system can help prevent defects and improve overall product quality.

Common Challenges in Metal Stamping

Despite its advantages, metal stamping comes with its own set of challenges. These can include material defects, tooling wear, and equipment malfunctions. Addressing these issues requires proper maintenance and regular inspections.

Advancements in Metal Stamping Technology

Technology in the field of metal stamping is constantly evolving. Advancements such as computer-aided design (CAD) and automation have significantly improved the efficiency and precision of the stamping process. Staying updated with the latest technologies can give manufacturers a competitive edge.

Environmental Considerations

The manufacturing industry is increasingly focusing on sustainability. Metal stamping processes should be designed to minimize waste and reduce environmental impact. Implementing eco-friendly practices can benefit both the environment and the bottom line.

Case Study: Successful Metal Stamping Implementation

To illustrate the effectiveness of metal stamping, consider a case study from a leading automotive manufacturer. By upgrading their stamping equipment and optimizing their processes, they achieved a 20% increase in production efficiency and reduced material waste by 15%.

Conclusion: Embracing Metal Stamping for Industrial Success

Metal stamping is a vital component of industrial manufacturing. By understanding the nuances of metal stamping equipment and implementing best practices, manufacturers can enhance their production capabilities and achieve success in the competitive market.

FAQs

What materials can be used in metal stamping?

Metals such as steel, aluminum, copper, and brass are commonly used in metal stamping.

What is the difference between mechanical and hydraulic presses?

Mechanical presses use a flywheel to generate force, while hydraulic presses use a hydraulic cylinder. Mechanical presses are known for speed, while hydraulic presses offer more control and versatility.

How can I improve the efficiency of my metal stamping process?

Improving efficiency can be achieved by upgrading equipment, investing in quality tooling, and implementing regular maintenance and quality control measures.

This article contains affiliate links. We may earn a commission at no extra cost to you.