In the rapidly evolving world of manufacturing, metal stamping automation technologies play a pivotal role in enhancing efficiency and productivity. These technologies are transforming how industries produce and fabricate metal components. As the demand for precision and speed increases, so does the need for advanced automation solutions.

What is Metal Stamping?

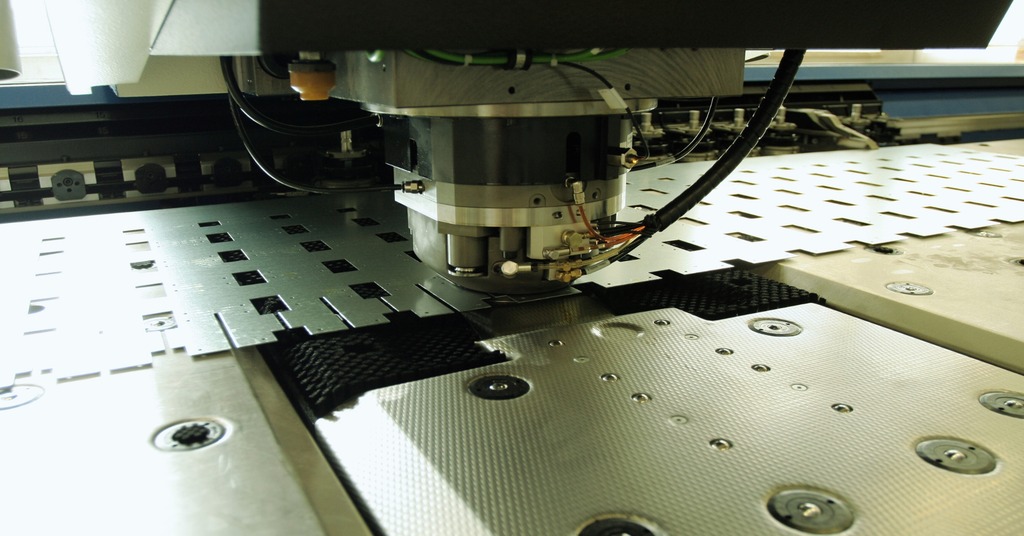

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It involves various techniques like punching, bending, and piercing. This process is crucial in producing parts for industries such as automotive, aerospace, and electronics.

The Role of Automation in Metal Stamping

Automation in metal stamping involves the use of machinery and technology to perform tasks that were traditionally done manually. This includes robotic arms, automated feeders, and computer-controlled systems that ensure precision and accuracy in production.

The Advantages of Metal Stamping Automation

Implementing metal stamping automation technologies comes with a multitude of advantages:

Increased Efficiency

Automation significantly boosts productivity by reducing the time taken to complete tasks. Machines can operate continuously without fatigue, unlike human workers.

Enhanced Precision

Automated systems provide exceptional precision, ensuring that every stamped part is identical. This consistency is crucial in sectors that require high tolerances.

Cost Reduction

While the initial investment in automation can be high, the long-term savings on labor and material waste make it a cost-effective solution.

Technological Innovations in Metal Stamping

The field of metal stamping automation is continuously evolving, with new technologies emerging to improve processes. Some of these innovations include:

Robotic Arms

Robotic arms are increasingly being integrated into metal stamping lines. They offer flexibility and can be programmed to handle various tasks, from material handling to assembly.

Computer Numerical Control (CNC)

CNC technology is widely used in stamping for its ability to produce complex designs with high accuracy. It allows for quick changes in design without the need for new tooling.

Impact on the Manufacturing Industry

Metal stamping automation technologies are reshaping the manufacturing landscape. By streamlining processes and reducing human error, these technologies are helping industries meet the growing demand for high-quality products.

Case Studies

Many companies have successfully implemented metal stamping automation to improve their operations. For instance, the automotive industry has seen significant improvements in production speed and quality through automation.

Challenges and Considerations

Despite the benefits, there are challenges associated with adopting metal stamping automation technologies. These include the high initial cost, the need for skilled personnel to manage the systems, and potential resistance to change from the workforce.

Training and Development

Investing in training for employees is essential to maximize the benefits of automation. Workers need to understand how to operate and maintain automated systems effectively.

Future of Metal Stamping Automation

The future of metal stamping automation looks promising, with advancements in artificial intelligence and machine learning set to further enhance capabilities. These technologies will enable even greater precision and efficiency, making manufacturing more competitive.

Sustainability and Automation

Sustainability is becoming a key focus in manufacturing. Metal stamping automation can contribute to this by minimizing waste and reducing energy consumption.

Conclusion

In conclusion, metal stamping automation technologies are revolutionizing the manufacturing sector. They offer numerous advantages, from increased efficiency and precision to cost savings and sustainability. As these technologies continue to evolve, they will undoubtedly play an even more significant role in shaping the future of manufacturing.

For more information on metal stamping processes, you can visit this guide.

FAQs

What industries benefit from metal stamping automation?

Industries such as automotive, aerospace, and electronics benefit significantly from metal stamping automation.

How does automation improve precision in metal stamping?

Automation uses advanced machinery and software to ensure each part is produced with exact specifications, reducing errors and inconsistencies.

What are the initial costs associated with metal stamping automation?

The initial costs can be high due to the investment in machinery and technology, but long-term savings make it a worthwhile investment.

This article contains affiliate links. We may earn a commission at no extra cost to you.