In the world of manufacturing, medical device metal stamping plays a critical role. This precise and efficient process is essential for creating high-quality components used in various medical devices. As industrial manufacturers continue to advance, understanding the significance of metal stamping in this sector becomes increasingly important.

The process of medical device metal stamping involves transforming flat metal sheets into specific shapes through a series of stamping operations. This method is favored for its ability to produce complex parts with high accuracy and repeatability. For those in the manufacturing industry, especially in the medical sector, mastering this process is crucial for meeting the stringent standards required.

Understanding the Basics of Metal Stamping

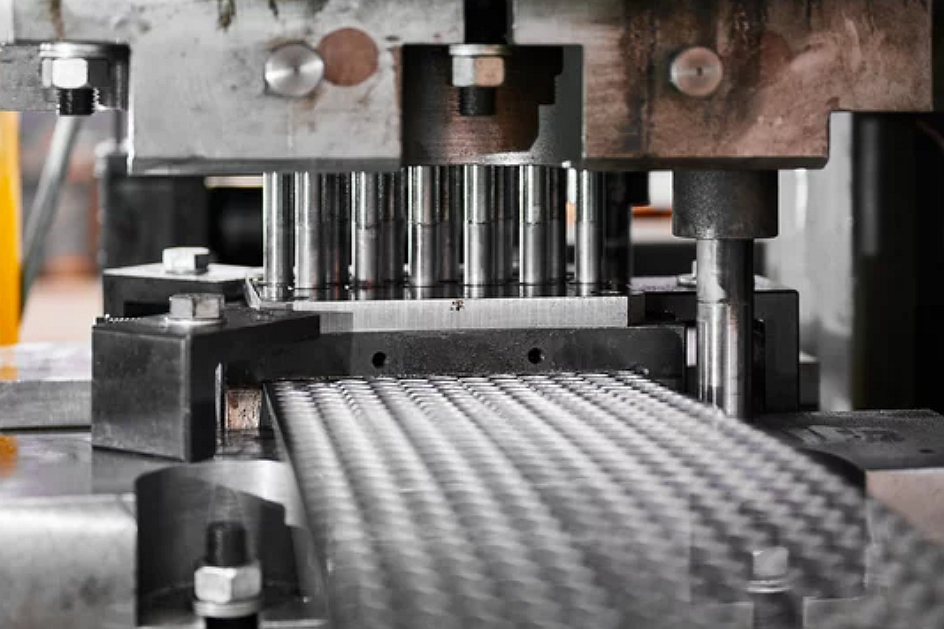

Metal stamping is a process that involves the use of a mechanical press to shape and cut metal sheets. It is a cost-effective method that allows for the production of large volumes of parts with consistent quality. This technique is widely used in the production of medical devices due to its precision and efficiency.

The Role of Metal Stamping in Medical Device Manufacturing

In the medical field, precision is key. Metal stamping provides the accuracy needed to produce parts that meet strict regulatory standards. From surgical instruments to implantable devices, the components created through metal stamping must be flawless to ensure patient safety and device efficacy.

Advantages of Metal Stamping for Medical Devices

One of the main advantages of metal stamping is its ability to produce intricate designs with high precision. This is particularly important in the medical industry, where even the smallest deviation can have significant consequences. Additionally, metal stamping is cost-effective, making it an attractive option for manufacturers looking to produce high volumes of parts.

Another key benefit is the versatility of metal stamping. It can be used to create a wide range of components, from simple brackets to complex surgical instruments. This flexibility makes it an ideal choice for manufacturers in the medical sector.

Key Considerations in Medical Device Metal Stamping

When it comes to medical device metal stamping, there are several key considerations to keep in mind. These include material selection, tooling, and quality control. Each of these factors plays a crucial role in ensuring the success of the stamping process.

Material Selection

Choosing the right material is essential for ensuring the durability and performance of stamped parts. In the medical industry, materials must be biocompatible and able to withstand sterilization processes. Common materials used in medical device metal stamping include stainless steel, titanium, and certain alloys.

Tooling and Equipment

The tooling used in metal stamping must be precise and durable. This is especially important in the medical sector, where the quality of stamped parts can directly impact patient safety. Advanced tooling technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), are often used to ensure the highest levels of precision and efficiency.

Quality Control

Quality control is a critical aspect of medical device metal stamping. Manufacturers must adhere to strict regulatory standards to ensure the safety and efficacy of their products. This involves rigorous testing and inspection of stamped parts to detect any defects or deviations from specifications.

Recent Innovations in Metal Stamping

As technology continues to advance, so too does the field of metal stamping. Recent innovations have led to the development of new techniques and materials, further enhancing the capabilities of this manufacturing process.

Advanced Materials

The use of advanced materials, such as shape memory alloys and biodegradable metals, is becoming increasingly common in medical device manufacturing. These materials offer unique properties that can enhance the performance and functionality of medical devices.

Automation and Robotics

Automation and robotics are transforming the metal stamping industry. By automating certain aspects of the stamping process, manufacturers can increase efficiency and reduce the risk of human error. This is particularly important in the medical sector, where precision is paramount.

Challenges in Medical Device Metal Stamping

Despite its many advantages, metal stamping does come with its challenges. Manufacturers must navigate issues such as tooling wear, material costs, and regulatory compliance. However, with careful planning and the right strategies, these challenges can be effectively managed.

Tooling Wear and Maintenance

Tooling wear is a common issue in metal stamping. Over time, the tools used in the stamping process can become worn, leading to a decrease in precision and quality. Regular maintenance and timely replacement of tooling are essential to ensure the continued success of the stamping process.

Material Costs

The cost of materials can be a significant factor in the overall cost of metal stamping. Manufacturers must carefully consider the cost of materials when planning their production processes. By optimizing material usage and exploring alternative materials, manufacturers can reduce costs and improve efficiency.

Regulatory Compliance

Compliance with regulatory standards is a critical aspect of medical device metal stamping. Manufacturers must ensure that their processes and products meet the stringent requirements set by regulatory bodies. This involves regular audits and inspections to ensure compliance.

The Future of Metal Stamping in the Medical Industry

The future of medical device metal stamping looks promising. With continued advancements in technology and materials, the capabilities of metal stamping are set to expand even further. This will open up new possibilities for the design and production of medical devices.

Emerging Technologies

Emerging technologies, such as additive manufacturing and 3D printing, are set to revolutionize the metal stamping industry. These technologies offer new ways to create complex parts with high precision, further enhancing the capabilities of metal stamping.

Sustainability and Environmental Impact

As the manufacturing industry continues to focus on sustainability, metal stamping is no exception. Manufacturers are increasingly looking for ways to reduce waste and minimize their environmental impact. This includes the use of eco-friendly materials and processes.

Conclusion

In conclusion, medical device metal stamping is a vital process in the manufacturing of medical devices. With its precision, efficiency, and versatility, metal stamping is well-suited to meet the needs of the medical industry. As technology continues to advance, the future of metal stamping looks bright, with new possibilities on the horizon.

FAQs

What is metal stamping?

Metal stamping is a manufacturing process that involves the use of a mechanical press to shape and cut metal sheets into specific forms. It is widely used in various industries, including automotive, aerospace, and medical.

Why is metal stamping important in the medical industry?

Metal stamping is important in the medical industry due to its precision and efficiency. It allows for the production of high-quality components that meet strict regulatory standards, ensuring the safety and efficacy of medical devices.

What are the common materials used in medical device metal stamping?

Common materials used in medical device metal stamping include stainless steel, titanium, and certain alloys. These materials are chosen for their biocompatibility and ability to withstand sterilization processes.

For more insights into the art of metal stamping, you might find this stamping 101 guide informative.

Explore more about the versatility of metal in art with metal mosaic projects and learn about creating laser-cut metal art.

This article contains affiliate links. We may earn a commission at no extra cost to you.