In today’s evolving industrial landscape, the significance of manual tools for precise metal cutting cannot be overstated. While advanced machinery continues to revolutionize metalwork, the indispensable role of manual tools remains pivotal. Understanding these tools provides a foundation for achieving precision and accurate metal cutting, essential attributes for manufacturers.

The Importance of Manual Tools in Metal Cutting

Despite technological advancements, manual tools retain their relevance. They offer unique benefits, notably in situations requiring intricate cuts or adjustments. As an industry professional, appreciating the nuances of precision metal cutting is crucial for achieving desired outcomes.

Essential Manual Tools for Precision Cutting

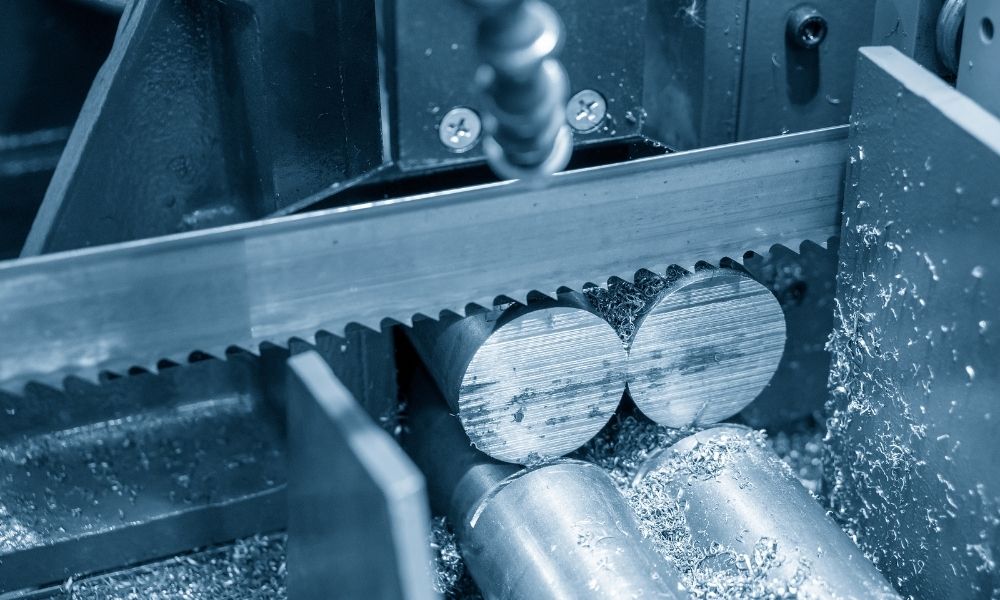

1. Hacksaws

Hacksaws are well-regarded for their simplicity and effectiveness. These basic tools are excellent for cutting thin metal sheets and bars, attributing to their lightweight designs and replaceable blades.

2. Files and Rasps

Metal files and rasps are designed to smoothen rough edges or shapes formed after initial cutting. Known for their role in providing a perfect finish, these tools are crucial in molding precise shapes.

3. Shears and Snips

Metal shears and snips are paramount for making accurate cuts in sheet metals. The sharp blades allow for clean, precise reductions, making it easier to achieve the targeted material dimensions.

4. Chisels

Chisels offer versatility, enabling artisans and manufacturers to carve or cut metals with exactitude. They aid in achieving specific design requirements, often integral in complex designs.

Optimizing Your Use of Manual Tools

To maximize the efficiency of manual tools for precise metal cutting, regular maintenance is necessary. Keeping tools sharp, clean, and corrosion-free not only promotes safety but enhances precision in cutting tasks.

Safety Tips for Manual Metal Cutting

Understanding safety protocols is paramount to preventing accidents. Consider wearing protective gear and ensuring proper tool handling, ensuring both personal safety and that of others around you.

For additional safety insights, consider exploring metal cutting safety tips on Modern Metalworks.

Integration with CAD Design

Incorporating manual cutting techniques with CAD designs can yield highly detailed and accurate metal products. Explore how technology complements traditional tools by visiting this guide on CAD design.

Incorporating Technology in Manual Practices

While manual tools are integral, integrating them with technological advancements is vital. The future of metal cutting lies in harmonizing traditional tools with automated systems, as demonstrated in ultrasonic metal cutting.

Choosing Right Tools for Aluminum

Cutting aluminum requires specific tools to ensure seamless, accurate results. Consider factors like tool strength and cutting ease when selecting suitable options. Visit our page on cutting aluminum for more information.

Frequently Asked Questions

1. Why are manual tools still relevant?

Manual tools provide artisanal control and precision, especially in complex designs, making them indispensable.

2. How can one maintain manual tools effectively?

Regular sharpening, cleaning, and appropriate storage can prolong their utility and efficiency in cutting tasks.

3. What are the best practices for using manual cutting tools?

Understanding each tool’s purpose, proper handling techniques, and consistent maintenance contribute to effective use.

External Resources

For a more extensive understanding of metal cutting techniques, refer to external sources, such as this resource on precision techniques.

As the industrial world continues to innovate, the integration of both manual and technological methodologies will define the future of metal cutting. Embrace this knowledge to enhance your craft.

This article contains affiliate links. We may earn a commission at no extra cost to you.