In the world of industrial manufacturing, ensuring the efficient operation and longevity of equipment is paramount. One critical aspect of maintaining this efficiency is the lubrication in die maintenance. The role of lubrication cannot be overstated; it is fundamental to the smooth operation and longevity of dies used in metal stamping processes. Proper lubrication ensures that the dies function optimally, reduces wear and tear, and ultimately leads to cost savings and improved productivity.

What is Die Maintenance?

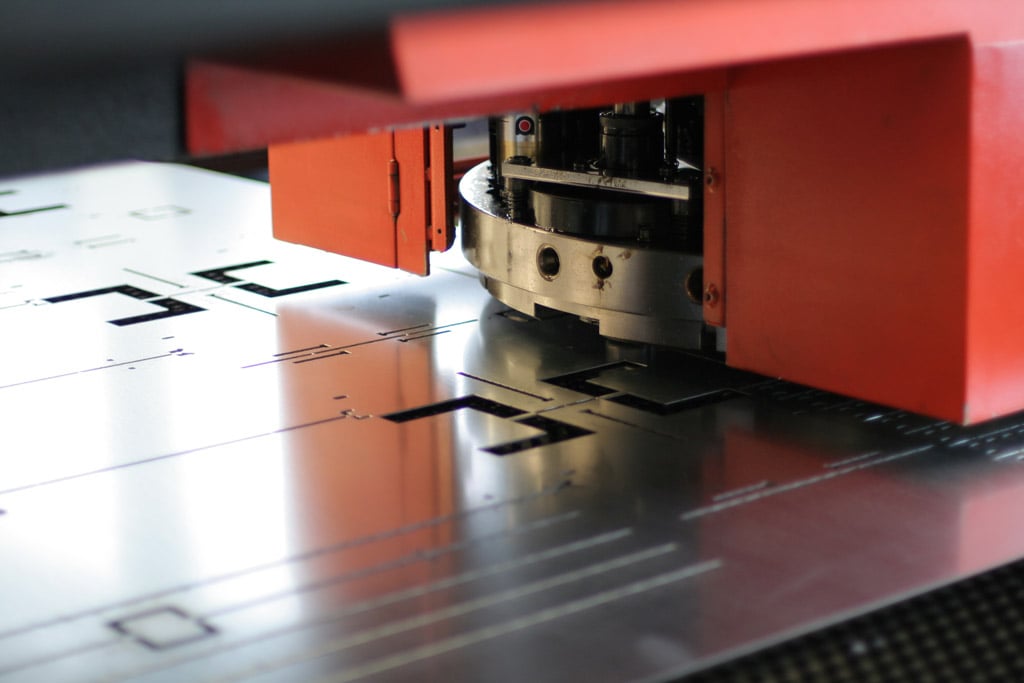

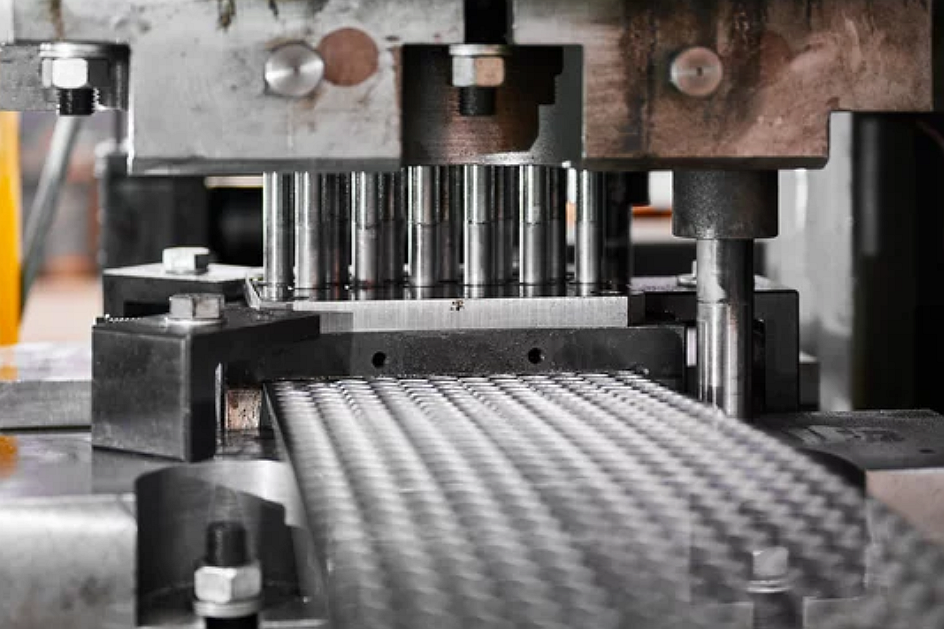

Die maintenance refers to the regular upkeep and repair of dies used in manufacturing. Dies are essential components in metal stamping, shaping, and cutting materials into desired forms. Without proper maintenance, dies can become worn out, leading to poor quality products and costly breakdowns.

Importance of Lubrication in Die Maintenance

The importance of lubrication in die maintenance cannot be understated. Lubrication helps in reducing friction between the die surfaces, preventing wear and prolonging the life of the die. This not only enhances the quality of the stamped products but also minimizes downtime due to die repair or replacement.

Types of Lubricants Used

There are various types of lubricants used in die maintenance, each with its specific application. These include oil-based, water-based, and synthetic lubricants. Choosing the right lubricant depends on the type of material being stamped, the operating conditions, and the desired finish of the product.

Benefits of Proper Lubrication

There are numerous benefits of proper lubrication in die maintenance. These include reduced wear and tear, improved product quality, reduced machine downtime, and longer die life. Proper lubrication also leads to cost savings as it reduces the need for frequent die replacements and repairs.

Challenges in Die Lubrication

While lubrication is essential, it also presents some challenges. These include selecting the right type of lubricant, applying the correct amount, and ensuring that the lubricant does not contaminate the finished product. Addressing these challenges is crucial for effective die maintenance.

Selecting the Right Lubricant

Selecting the right lubricant is a critical step in die maintenance. Factors to consider include the material being stamped, the operating temperature, and the desired finish. Consulting with lubricant manufacturers can help in making the right choice.

Application Techniques

There are different application techniques for lubricants, each suited for specific scenarios. These include manual application, spraying, and automated lubrication systems. The choice of technique depends on the production scale and the complexity of the die design.

Innovations in Lubrication Technology

Recent innovations in lubrication technology have led to the development of advanced lubricants and application systems. These innovations aim to improve efficiency, reduce environmental impact, and enhance product quality.

Environmental Considerations

Environmental considerations are becoming increasingly important in lubrication technology. Manufacturers are now focusing on developing eco-friendly lubricants that minimize environmental impact while maintaining performance.

Training and Best Practices

Proper training and adherence to best practices are essential for effective die lubrication. Operators should be trained in selecting and applying lubricants, as well as recognizing signs of wear and troubleshooting issues.

Regular Inspections

Regular inspections are a crucial part of die maintenance. They help in identifying wear and lubrication issues before they lead to costly breakdowns. Regular inspections ensure that the dies are in optimal condition for production.

Conclusion

In conclusion, lubrication in die maintenance is a critical aspect of industrial manufacturing. Proper lubrication ensures the longevity of dies, reduces wear, and improves product quality. By overcoming challenges and embracing innovations, manufacturers can achieve significant cost savings and enhanced productivity.

FAQs

Why is lubrication important in die maintenance?

Lubrication is important because it reduces friction, prevents wear, and prolongs the life of the die, ensuring efficient production and high-quality products.

What types of lubricants are used in die maintenance?

Common types of lubricants include oil-based, water-based, and synthetic lubricants, each suited for specific applications and conditions.

How can I choose the right lubricant for my dies?

Choosing the right lubricant involves considering factors such as the material being stamped, operating conditions, and desired product finish. Consulting with lubricant manufacturers can provide valuable insights.

For further insights into metal stamping processes, click here.

This article contains affiliate links. We may earn a commission at no extra cost to you.