In today’s fast-paced industrial landscape, maintaining competitive advantage is crucial for manufacturers. Implementing lean manufacturing in stamping operations is a transformative strategy that can significantly enhance efficiency, reduce waste, and improve overall productivity. This article explores the principles of lean manufacturing, its application in stamping operations, and the benefits it offers to the industry.

Understanding Lean Manufacturing

Lean manufacturing is a systematic approach to minimizing waste without compromising productivity. Originating from the Toyota Production System, it focuses on creating value for the end customer. The core idea is to optimize processes, eliminate unnecessary activities, and continuously improve operations.

In stamping operations, lean manufacturing involves streamlining processes, reducing lead times, and ensuring that each step in the production line adds value. By adopting lean principles, manufacturers can enhance their operational efficiency and deliver high-quality products.

Key Principles of Lean Manufacturing

- Value Stream Mapping: This involves analyzing the flow of materials and information to identify areas of waste and improvement.

- Kaizen: A philosophy of continuous improvement where small, incremental changes lead to significant enhancements.

- 5S Methodology: Organizing the workplace for efficiency and effectiveness by sorting, setting in order, shining, standardizing, and sustaining.

- Just-In-Time (JIT): Reducing inventory costs by producing only what is needed, when it is needed.

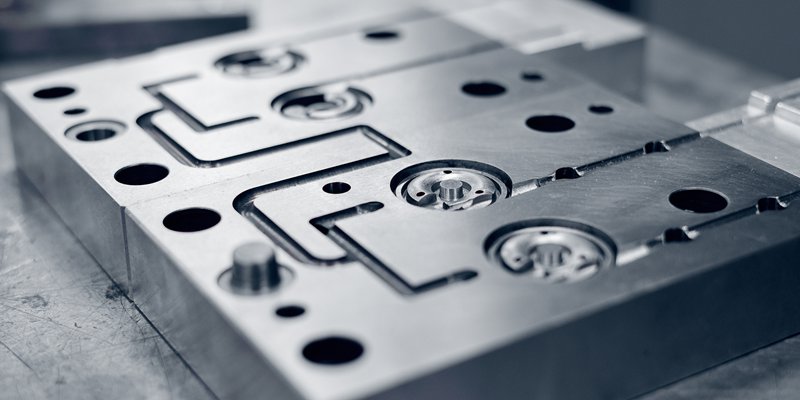

Applying Lean Manufacturing in Stamping Operations

Incorporating lean manufacturing principles into stamping operations involves several strategic approaches:

Streamlining Production Processes

One of the primary goals is to streamline production processes. By analyzing each step in the stamping process, manufacturers can identify bottlenecks and areas of waste. Implementing efficient workflows and reducing unnecessary movements can significantly enhance productivity. For more insights on improving productivity in stamping operations, visit stamping press productivity.

Reducing Waste and Variability

Lean manufacturing emphasizes the reduction of waste and variability. By standardizing processes and implementing quality control measures, manufacturers can minimize defects and rework. This not only improves product quality but also reduces costs. Learn more about quality control in stamping production here.

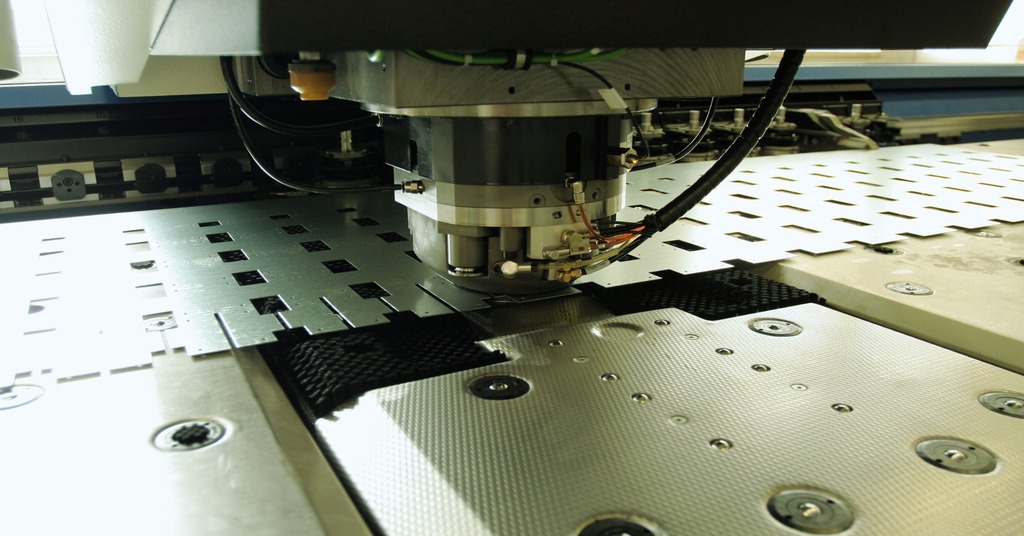

Enhancing Equipment Efficiency

Regular maintenance and timely upgrades of stamping equipment are crucial for maintaining efficiency. By investing in advanced machinery and technology, manufacturers can enhance precision and reduce downtime. To make informed decisions about equipment investments, consider the insights on used vs new stamping equipment.

Benefits of Lean Manufacturing in Stamping Operations

Implementing lean manufacturing in stamping operations offers numerous benefits:

- Cost Reduction: By minimizing waste and optimizing processes, manufacturers can significantly reduce operational costs.

- Improved Quality: Standardized processes and quality control measures ensure consistent product quality.

- Increased Flexibility: Lean manufacturing allows manufacturers to quickly adapt to changes in demand and production requirements.

- Enhanced Employee Engagement: Involving employees in continuous improvement fosters a culture of innovation and engagement.

Challenges in Implementing Lean Manufacturing

While the benefits are substantial, implementing lean manufacturing in stamping operations can pose challenges:

Resistance to Change

Employees may resist changes to established processes. Overcoming this requires effective communication and involving employees in the improvement process.

Initial Investment Costs

Investing in new equipment and training can be costly. However, the long-term benefits often outweigh the initial expenses.

Sustaining Improvements

Maintaining the momentum of continuous improvement requires ongoing commitment from management and employees.

Future of Lean Manufacturing in Stamping Operations

The future of lean manufacturing in stamping operations looks promising. With advancements in technology and the increasing demand for efficient production methods, lean principles will continue to play a pivotal role in shaping the industry. The adoption of digital tools and automation will further enhance the capabilities of lean manufacturing, enabling manufacturers to achieve unprecedented levels of efficiency.

Additional Resources

For a deeper understanding of stamping operations and their intricacies, consider exploring external resources such as the anatomy of a mechanical stamping press. Understanding the mechanics of stamping equipment can provide valuable insights into optimizing operations.

Conclusion

In conclusion, implementing lean manufacturing in stamping operations is a strategic approach that can drive efficiency, reduce costs, and enhance product quality. By embracing lean principles and continuously improving processes, manufacturers can position themselves for success in the competitive industrial landscape. The journey towards lean manufacturing is ongoing, but the rewards are well worth the effort.

FAQ

What is lean manufacturing?

Lean manufacturing is a systematic approach to minimizing waste in production processes without compromising productivity.

How does lean manufacturing benefit stamping operations?

Lean manufacturing enhances stamping operations by reducing waste, improving quality, increasing flexibility, and engaging employees in continuous improvement.

What are the challenges in implementing lean manufacturing?

Challenges include resistance to change, initial investment costs, and sustaining continuous improvement efforts.

This article contains affiliate links. We may earn a commission at no extra cost to you.