In the world of modern manufacturing, understanding the differences between laser engraving vs. cutting is essential for industrial manufacturers. These two processes, while similar in their use of laser technology, serve distinctly different purposes. The use of lasers in manufacturing has revolutionized how products are designed and created, offering precision and versatility. This article delves into the fundamental differences, applications, and benefits of these two processes, helping industry professionals make informed decisions.

What is Laser Technology?

Laser technology involves the use of focused light beams to perform tasks such as cutting, engraving, and marking on various materials. It is a critical component in modern manufacturing due to its precision and efficiency. Lasers can cut intricate patterns, engrave detailed images, and mark materials with information, all while maintaining high levels of accuracy.

Defining Laser Engraving

Laser engraving is a process that uses lasers to etch designs, text, or logos onto a material’s surface. It involves removing a portion of the material to create a permanent mark. This process is highly valued for its ability to create detailed and precise images and is widely used in industries such as jewelry, signage, and electronics.

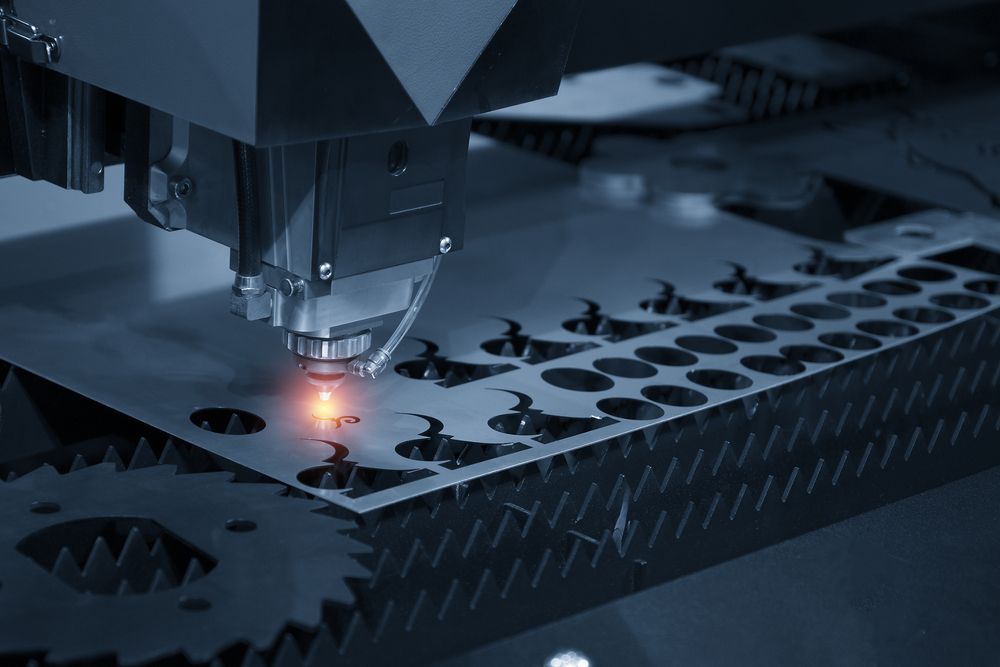

Understanding Laser Cutting

On the other hand, laser cutting is a method of slicing through materials using a laser. This process is utilized to cut parts from sheet metal, plastics, wood, and other materials. The precision of laser cutting is unmatched, making it ideal for industries that require exact specifications, such as aerospace and automotive manufacturing.

Key Differences Between Laser Engraving and Cutting

Purpose and Application

The primary difference lies in their purpose. Laser engraving is primarily used for marking or etching, while laser cutting is used for cutting through materials. These processes are employed in different scenarios based on the desired outcome.

Depth and Material Removal

Laser engraving involves removing a small amount of material to leave a permanent mark. In contrast, laser cutting involves slicing through the entire material. This difference in depth of cut or engraving significantly impacts the choice of process for a given application.

Material Usage

Both processes can be used on a wide range of materials. However, laser engraving is often used on more delicate surfaces, while laser cutting is used for thicker and more robust materials. The choice of material can influence the quality and precision of the final product.

Benefits of Laser Engraving

Laser engraving offers numerous advantages, including high precision, versatility, and the ability to create intricate designs. It is a non-contact process, meaning there is minimal risk of damaging the material. This makes it ideal for delicate items where precision is paramount.

Benefits of Laser Cutting

Laser cutting is renowned for its speed and accuracy. It allows manufacturers to produce parts with high precision and minimal waste. The ability to cut complex shapes efficiently makes it a preferred choice for industries that require detailed and accurate products. For more insights on precision cutting, you can visit an external resource [here](https://profusionusa.com/precision-cutting/) (nofollow).

Applications of Laser Engraving

The applications of laser engraving are vast, spanning industries such as advertising, electronics, and fashion. It is commonly used to personalize items, create branding materials, and produce intricate designs on a range of surfaces.

Applications of Laser Cutting

Laser cutting is widely used in manufacturing industries to produce parts for machinery, vehicles, and electronics. It is also employed in the creation of architectural models, signs, and various consumer products. For more on metal cutting techniques, check this internal link on carbon steel cutting.

Choosing Between Laser Engraving and Cutting

The choice between laser engraving vs. cutting depends on the project requirements. Factors such as material type, desired outcome, and production speed all play a role in deciding which process to use.

Technological Advancements in Laser Processes

Recent advancements in laser technology have enhanced the efficiency and capabilities of both engraving and cutting. Modern laser machines offer improved precision, faster processing times, and greater flexibility. Laser cutting software has also evolved, allowing for more complex designs and optimized material usage.

Cost Implications

While both processes involve initial investment in laser equipment, the long-term benefits of reduced material waste and increased production efficiency often outweigh the costs. The specific cost implications depend on the scale of the operation and the type of materials used.

Environmental Considerations

Both laser engraving and laser cutting are environmentally friendly processes, as they produce minimal waste and require no chemicals. This makes them a sustainable choice for modern manufacturing practices.

Future Trends in Laser Technology

The future of laser technology in manufacturing looks bright, with continuous improvements expected in speed, precision, and versatility. As technology advances, the applications for laser engraving vs. cutting are likely to expand, offering even more possibilities for industrial manufacturers.

Conclusion

Understanding the differences between laser engraving vs. cutting is crucial for industrial manufacturers looking to optimize their production processes. Both technologies offer unique advantages and applications, making them integral to modern manufacturing. By choosing the right process for the right application, manufacturers can enhance their productivity, reduce costs, and achieve superior quality products.

FAQs

What materials can be used for laser engraving?

Laser engraving can be used on a variety of materials including metals, plastics, glass, and wood. The choice of material depends on the desired outcome and application.

Is laser cutting more precise than traditional cutting methods?

Yes, laser cutting is generally more precise than traditional methods due to its ability to produce intricate patterns with minimal waste. For more on cutting techniques, see our article on CNC vs manual cutting.

How do laser engraving and cutting impact the environment?

Both processes have a minimal environmental impact as they produce little waste and require no harmful chemicals, making them sustainable options for manufacturers.

This article contains affiliate links. We may earn a commission at no extra cost to you.