In today’s fast-paced world of industrial manufacturing, efficiency and innovation are key to staying competitive. One remarkable advancement that has been gaining traction is in-die tapping technology. This innovative approach is transforming the way manufacturers operate by streamlining processes and enhancing productivity. Understanding its impact is crucial for any company looking to improve its operations.

What is In-Die Tapping Technology?

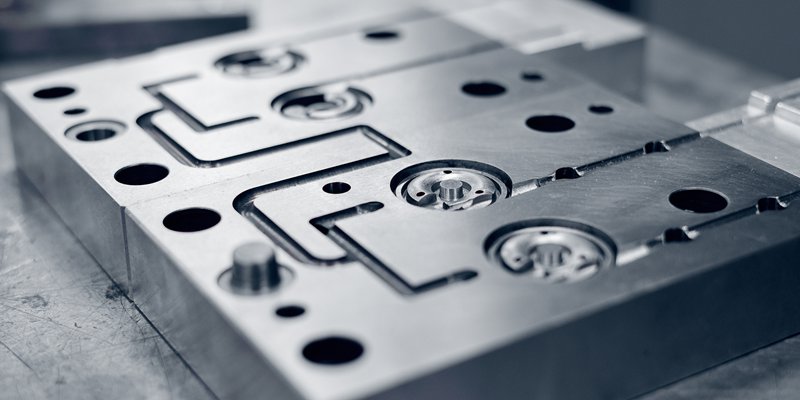

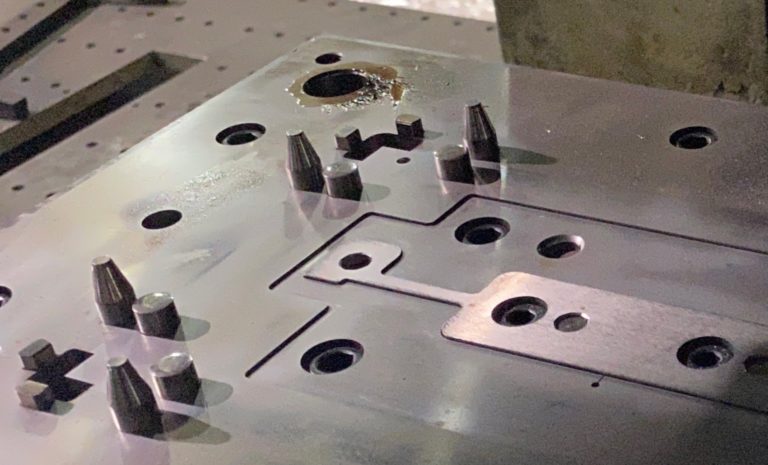

In-die tapping technology refers to the process of integrating tapping operations directly into the stamping die. This means that the process of creating threads in a material occurs simultaneously with the stamping operation. This integration leads to significant time savings and reduces the need for secondary operations, making it a highly efficient solution for many manufacturers.

The Benefits of In-Die Tapping Technology

The advantages of incorporating in-die tapping technology into your manufacturing processes are numerous:

1. Increased Efficiency

By eliminating the need for separate tapping operations, manufacturers can significantly reduce cycle times. This efficiency leads to higher throughput and allows companies to meet demand more effectively. For more insights on how to improve stamping processes, check stamping productivity.

2. Cost Savings

One of the most compelling benefits of in-die tapping technology is cost reduction. By integrating tapping into the stamping process, companies can minimize labor costs and reduce the need for additional machinery and floor space. This streamlined process also leads to fewer errors, reducing waste and associated costs.

3. Improved Quality

The precision of in-die tapping technology ensures that threads are consistently accurate, leading to higher quality products. With the tapping operation integrated into the die, there is less opportunity for misalignment or errors, which can occur in separate operations. To learn about enhancing quality in metal stamping, visit vibration analysis.

Applications of In-Die Tapping Technology

This technology is applicable in various industries, including automotive, aerospace, and consumer electronics. Manufacturers in these sectors can benefit from the improved efficiency and quality that in-die tapping technology offers. For instance, in the automotive industry, where precision and speed are paramount, this technology can lead to substantial improvements in production timelines and product quality.

Implementing In-Die Tapping Technology

1. Assessing Your Needs

Before implementing in-die tapping technology, it’s essential to assess your specific manufacturing needs. Consider factors such as production volume, part complexity, and existing equipment. This assessment will help determine if the integration of this technology is a suitable fit for your operations.

2. Choosing the Right Equipment

Selecting the appropriate equipment is crucial for successful implementation. Work with experienced suppliers who understand the nuances of in-die tapping technology to ensure you choose the right machinery for your needs. This decision will have a significant impact on the effectiveness of the technology in your facility.

3. Training and Support

Proper training for your workforce is essential to maximize the benefits of in-die tapping technology. Ensure your team is well-versed in operating the equipment and understands the intricacies of the integrated process. Ongoing support from your supplier can also play a crucial role in maintaining efficiency and addressing any challenges that may arise.

Challenges and Considerations

While the benefits of in-die tapping technology are substantial, there are challenges to consider. These include the initial cost of equipment, the need for skilled operators, and potential maintenance requirements. However, with careful planning and execution, these challenges can be mitigated, making the investment worthwhile.

Future Trends in In-Die Tapping Technology

The future of in-die tapping technology looks promising, with ongoing advancements in automation and technology. As industries continue to evolve, this technology will likely become even more integral to manufacturing processes, offering enhanced capabilities and further reducing production times and costs.

Conclusion

In conclusion, in-die tapping technology is a transformative advancement in the world of industrial manufacturing. Its ability to streamline processes, reduce costs, and improve product quality makes it an invaluable asset for manufacturers across various industries. By carefully considering your company’s needs and investing in this technology, you can position your business for greater success and competitiveness in the market.

FAQs About In-Die Tapping Technology

1. What industries benefit most from in-die tapping technology?

Industries such as automotive, aerospace, and consumer electronics benefit significantly from this technology due to their high production volumes and need for precision.

2. How does in-die tapping technology reduce costs?

This technology reduces costs by eliminating the need for separate tapping operations, reducing labor expenses, and minimizing waste through increased accuracy.

3. Is it challenging to implement in-die tapping technology?

While there are challenges, such as the initial investment and training requirements, these can be managed with careful planning and support from experienced suppliers.

For more information on the metal stamping process, visit metal stamping 101.

This article contains affiliate links. We may earn a commission at no extra cost to you.