The manufacturing sector is constantly evolving, and one of the most significant advancements in recent years is the implementation of in-die fastener insertion technology. This cutting-edge process is transforming the way industrial manufacturers operate, allowing for increased efficiency, precision, and cost-effectiveness. By integrating fastener insertion directly into the stamping process, companies can streamline their operations and enhance their overall productivity.

In this article, we will delve deep into the world of in-die fastener insertion technology, exploring its benefits, applications, and impact on the manufacturing industry. Whether you are an industry veteran or new to the world of industrial manufacturing, understanding this technology is crucial for staying competitive in today’s fast-paced market.

The Basics of In-Die Fastener Insertion

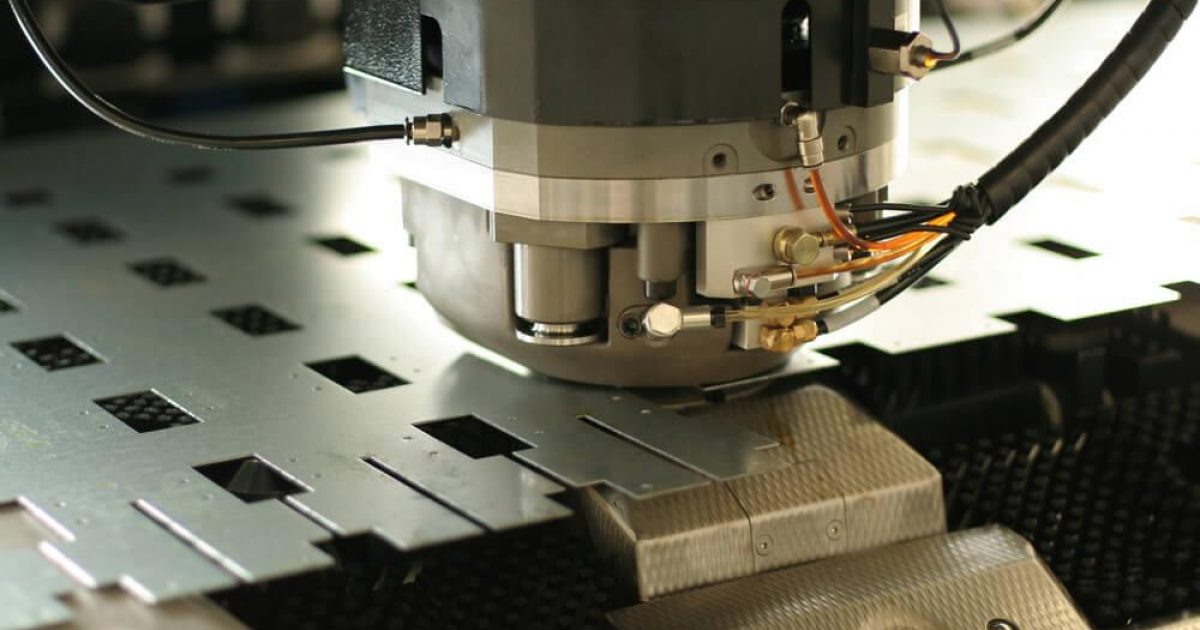

At its core, in-die fastener insertion technology involves integrating the insertion of fasteners, such as nuts, studs, or bushings, directly into the metal stamping process. This eliminates the need for secondary operations, reducing production time and costs. The technology utilizes advanced machinery that precisely places fasteners into the metal die during the stamping process, ensuring accuracy and consistency.

How Does It Work?

The process begins with the design of a specialized die that incorporates fastener insertion capabilities. During the stamping operation, the die simultaneously performs traditional stamping tasks while inserting fasteners into the desired locations. This seamless integration allows for a smooth and efficient production process, minimizing the risk of errors and defects.

Advantages of In-Die Fastener Insertion Technology

1. Increased Efficiency

By eliminating the need for separate fastener insertion processes, manufacturers can significantly reduce production time and labor costs. The streamlined workflow results in faster turnaround times and increased overall efficiency.

2. Enhanced Precision

The integration of fastener insertion into the stamping process ensures precise placement and alignment of fasteners, reducing the likelihood of errors and defects. This precision is especially crucial in industries where accuracy is paramount, such as automotive and aerospace.

3. Cost Savings

The reduction in production time and labor costs translates to significant cost savings for manufacturers. Additionally, the elimination of secondary operations reduces the need for additional equipment and maintenance, further lowering expenses.

4. Improved Quality

With in-die fastener insertion technology, manufacturers can achieve higher quality standards by ensuring consistent and reliable fastener placement. This results in finished products that meet or exceed industry specifications.

Applications of In-Die Fastener Insertion Technology

This technology is utilized across various industries, each benefiting from its unique advantages:

Automotive Industry

In the automotive sector, precision and efficiency are crucial. In-die fastener insertion allows for the seamless integration of fasteners into automotive components, enhancing structural integrity and reducing assembly time.

Aerospace Industry

For aerospace manufacturers, precision is non-negotiable. This technology ensures the accurate placement of fasteners in aerospace components, contributing to the overall safety and reliability of aircraft.

Consumer Electronics

In the consumer electronics industry, where miniaturization is key, in-die fastener insertion enables the precise placement of tiny fasteners in electronic devices, ensuring functionality and durability.

Challenges and Considerations

While in-die fastener insertion technology offers numerous advantages, there are challenges to consider:

Initial Investment

Implementing this technology requires a significant initial investment in specialized machinery and training. However, the long-term cost savings and efficiency gains often outweigh the upfront costs.

Complexity of Design

Designing dies with integrated fastener insertion capabilities can be complex and requires expertise. Manufacturers must ensure that their design teams are well-versed in this technology to maximize its benefits.

Maintenance and Upkeep

Regular maintenance and upkeep are essential to ensure the continued performance of the machinery. Manufacturers must invest in proper maintenance protocols to prevent downtime and ensure optimal operation.

The Future of In-Die Fastener Insertion Technology

As technology continues to advance, we can expect further innovations in in-die fastener insertion. Automation and digitalization are likely to play a significant role in enhancing the capabilities and efficiency of this technology. Additionally, as more industries recognize its benefits, the demand for skilled professionals in this field is expected to grow.

For a deeper understanding of how in-die fastener insertion technology fits into the broader context of manufacturing advancements, check out this How Stamping Press Works.

Conclusion

In-die fastener insertion technology is revolutionizing the manufacturing industry by offering increased efficiency, precision, and cost savings. Its applications span across various sectors, from automotive to aerospace, showcasing its versatility and impact. As this technology continues to evolve, manufacturers must stay informed and adapt to remain competitive in the ever-changing landscape of industrial manufacturing.

FAQs

1. What is in-die fastener insertion technology?

It is a process that integrates the insertion of fasteners directly into the metal stamping process, eliminating the need for secondary operations.

2. What industries benefit from this technology?

Industries such as automotive, aerospace, and consumer electronics benefit greatly from the precision and efficiency of in-die fastener insertion.

3. Are there any challenges associated with this technology?

Yes, challenges include the initial investment in machinery and training, complexity in die design, and the need for regular maintenance.

This article contains affiliate links. We may earn a commission at no extra cost to you.