When it comes to the world of industrial manufacturing, the choice between hydraulic vs mechanical stamping presses is a pivotal decision that can impact efficiency, cost, and the quality of the final product. In this comprehensive guide, we will delve into the intricacies of both types of presses, providing insights that will help manufacturers make informed decisions. Whether you’re involved in metal garden art or large-scale industrial projects, understanding these presses is crucial.

Understanding Stamping Presses: An Overview

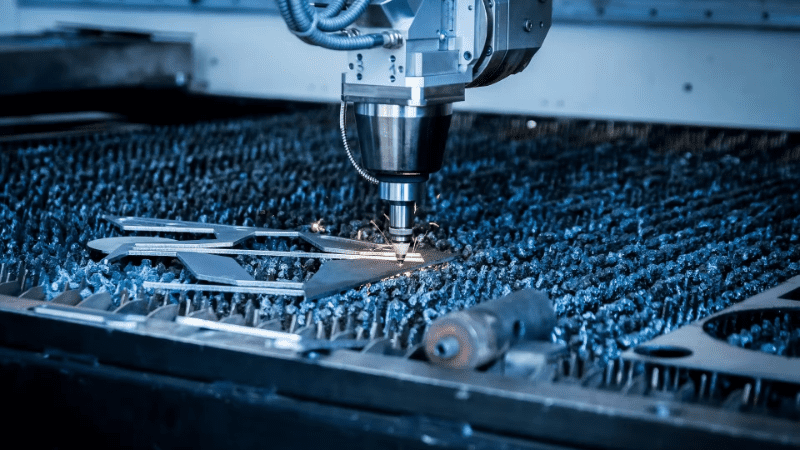

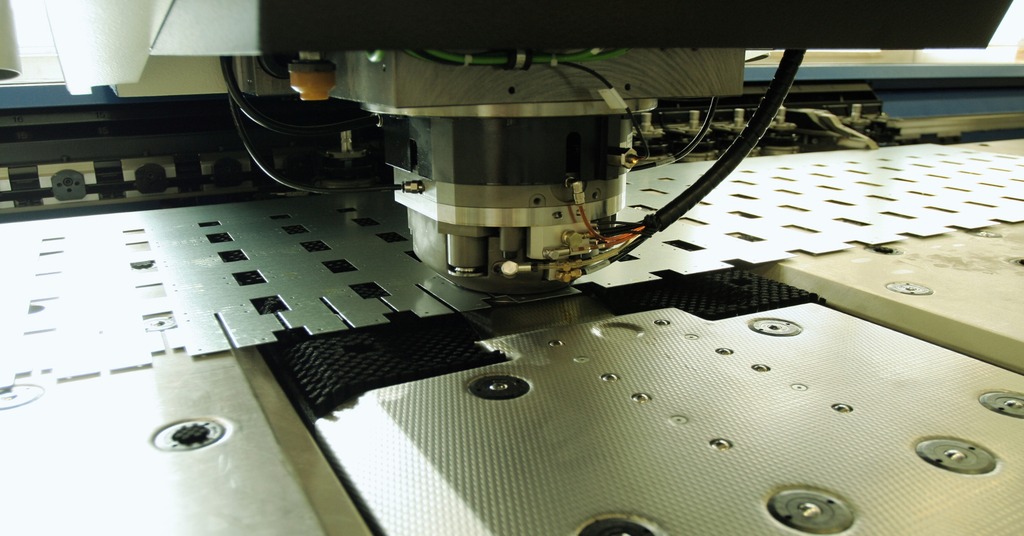

Stamping presses are fundamental machines in the manufacturing industry, used to shape or cut metal by deforming it with a die. They are used in various applications, from automotive components to metal mosaics.

Types of Stamping Presses

There are primarily two types of stamping presses: hydraulic presses and mechanical presses. Each has its unique set of advantages and disadvantages.

Hydraulic Stamping Presses

How Do Hydraulic Presses Work?

Hydraulic presses utilize a hydraulic cylinder to generate a compressive force. By using liquid pressure, these presses can provide consistent and controllable force, which is ideal for tasks requiring precision.

Advantages of Hydraulic Presses

- Precision and Control: Hydraulic presses offer superior control over the force applied, making them ideal for intricate work.

- Versatility: They can be used for a wide range of materials and applications.

- Safety: Hydraulic presses often incorporate safety features to prevent accidents.

Disadvantages of Hydraulic Presses

- Speed: Generally slower than mechanical presses.

- Maintenance: Requires regular maintenance to prevent leaks and ensure optimal performance.

Mechanical Stamping Presses

How Do Mechanical Presses Work?

Mechanical presses operate with a motor-driven flywheel that stores energy and releases it to perform the stamping operation. This makes them suitable for high-speed production.

Advantages of Mechanical Presses

- Speed and Efficiency: Ideal for high-volume production due to their rapid operation.

- Durability: Known for their robust construction and long-lasting performance.

Disadvantages of Mechanical Presses

- Flexibility: Less adaptable than hydraulic presses for different materials and applications.

- Noise: Typically noisier than hydraulic presses.

Comparing Hydraulic vs Mechanical Presses

Choosing between hydraulic vs mechanical stamping presses involves weighing the benefits and drawbacks of each type relative to the specific needs of the production process. For instance, if your operation demands speed and high-volume output, a mechanical press might be the better choice. Conversely, if precision and versatility are paramount, a hydraulic press is more suitable.

Cost Considerations

Cost is a critical factor in determining the right press. Mechanical presses often have a higher initial cost but lower operational costs over time. Hydraulic presses, while possibly cheaper upfront, may incur higher maintenance expenses.

Space and Infrastructure

Mechanical presses typically require more space and infrastructure due to their size and operational demands. Hydraulic presses, on the other hand, are often more compact.

Applications in Industry

Both types of presses are used across various industries. Mechanical presses are prevalent in automotive manufacturing due to their speed, while hydraulic presses are favored in industries requiring precision, such as aerospace and laser-cut metal art.

Future Trends in Stamping Press Technology

As technology advances, both hydraulic and mechanical presses are evolving. Innovations are focused on improving efficiency, reducing environmental impact, and enhancing safety. For example, hybrid presses that combine features of both types are emerging as a promising solution for modern manufacturing challenges.

Conclusion

In the debate between hydraulic vs mechanical stamping presses, the right choice depends on your specific manufacturing needs. By understanding the strengths and limitations of each type, manufacturers can select the press that aligns with their production goals and operational requirements.

FAQs

What is the main difference between hydraulic and mechanical presses?

The primary difference lies in the way force is generated and applied. Hydraulic presses use fluid pressure, offering greater control and precision, while mechanical presses use kinetic energy from a flywheel, making them faster and more suited for high-volume production.

Which type of press is more cost-effective?

This depends on the specific application and production volume. Mechanical presses may be more cost-effective for high-volume production, while hydraulic presses might be better for precision tasks that require flexibility.

Are there hybrid options available?

Yes, hybrid presses are becoming increasingly popular as they combine the benefits of both hydraulic and mechanical systems, offering versatility and efficiency in one package.

For more information about the workings of stamping presses, you can visit this detailed guide.

This article contains affiliate links. We may earn a commission at no extra cost to you.