When it comes to choosing between a hydraulic press and a stamping press, industrial manufacturers often face a challenging decision. Both machines are essential in the manufacturing process but serve different purposes. In this article, we’ll explore the differences, advantages, and potential uses of each to help you make an informed choice.

Hydraulic press vs stamping press is a common comparison in the manufacturing world. It’s crucial to understand these machines’ roles because selecting the right one can impact productivity, quality, and cost. Let’s dive in to discover which might be best suited for your needs.

Understanding the Basics

What is a Hydraulic Press?

A hydraulic press is a machine that uses a hydraulic cylinder to generate a compressive force. This press is highly versatile and can be used for a wide range of applications, such as molding, forging, and assembling. The force applied by a hydraulic press is uniform and consistent, making it ideal for tasks that require precision.

What is a Stamping Press?

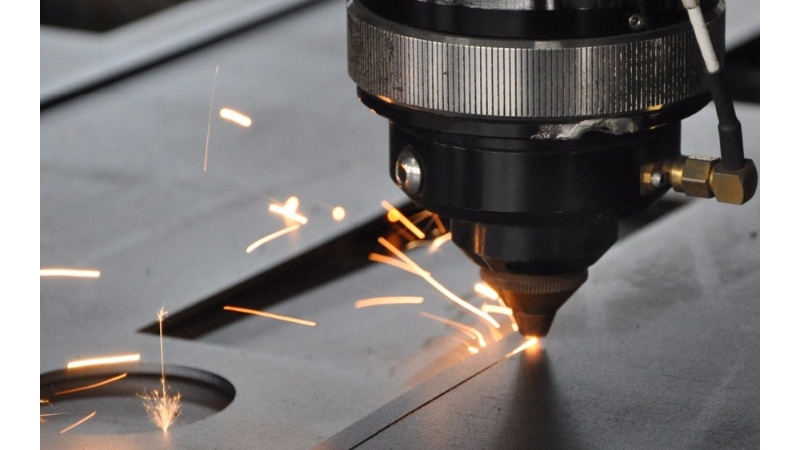

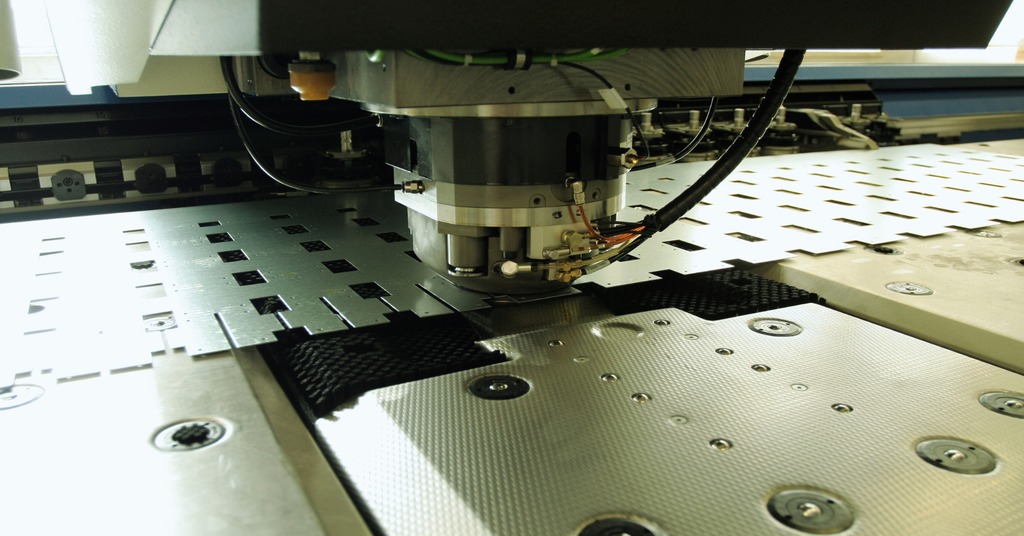

A stamping press, on the other hand, is designed to cut or shape material, usually metal, by applying pressure with a die. Stamping presses are commonly used in mass production settings to create parts for automobiles, appliances, and other consumer goods. They are known for their speed and efficiency in high-volume production.

Key Differences

Force Application

The main difference between a hydraulic press and a stamping press is the way they apply force. Hydraulic presses use fluid to create pressure, offering a steady and controlled force, while stamping presses use mechanical action, which can be less consistent but faster.

Precision vs Speed

If your project requires precise and uniform pressure, a hydraulic press might be your best bet. However, if speed and efficiency are your priorities, especially in mass production, a stamping press could be the better choice.

Material Compatibility

Both presses can work with a variety of materials, but hydraulic presses are often favored for materials that require careful handling due to their controlled pressure application. Stamping presses excel with metals and are ideal for tasks that involve cutting and shaping.

Advantages of Hydraulic Presses

Hydraulic presses offer several advantages:

- Precision: The consistent pressure makes them perfect for delicate tasks.

- Versatility: They can be used for many different applications.

- Control: The ability to adjust pressure allows for greater control over the process.

Advantages of Stamping Presses

Meanwhile, stamping presses are beneficial for:

- Speed: They are designed for high-volume production.

- Cost-Effectiveness: Ideal for mass production, reducing per-unit costs.

- Efficiency: Quick setup and operation times.

Applications in Industry

Both hydraulic presses and stamping presses play crucial roles in various industries. In automotive manufacturing, for example, stamping presses are often used to produce body panels, while hydraulic presses might be used for forming or assembling components. For more on improving stamping productivity, check out our detailed guide.

Factors to Consider When Choosing

Production Volume

Consider the volume of production. If you are dealing with large-scale production, a stamping press might be more suitable due to its speed.

Material and Product Type

The type of material and product you are dealing with can also influence your decision. For intricate and delicate materials, hydraulic presses might be preferable.

Budget

Budget constraints are always a consideration. While hydraulic presses offer versatility, they can be more expensive than stamping presses, especially for high-volume applications.

Latest Innovations

Both pressing technologies have seen advancements. Modern hydraulic presses offer enhanced precision and control, while stamping presses have become more efficient and environmentally friendly. For insights on whether to opt for new or used equipment, explore our comprehensive breakdown.

Quality Control and Maintenance

Maintaining quality in production is paramount. Regular maintenance ensures both types of presses perform optimally. For more on quality control practices in stamping, visit our resource page.

Future Trends

The future of pressing technology is bright, with innovations aimed at increasing efficiency and reducing environmental impact. Hydraulic presses are incorporating smart technologies for better control, while stamping presses are advancing towards faster and more sustainable operations.

Conclusion

Choosing between a hydraulic press and a stamping press depends on your specific needs and goals. Whether it’s precision, speed, or cost-effectiveness, understanding the strengths and limitations of each press will guide you in making the right decision.

Frequently Asked Questions

1. Can hydraulic presses handle high-volume production?

Yes, while hydraulic presses are not typically as fast as stamping presses, they can handle high-volume production with consistent quality.

2. Are stamping presses suitable for all materials?

Stamping presses are best suited for metals but can work with other materials. However, for delicate or non-metal materials, a hydraulic press might be more appropriate.

3. How do I decide between buying new or used equipment?

Consider your budget, production requirements, and the technological advancements of new machines. For a detailed comparison, see our article on used vs new equipment.

This article contains affiliate links. We may earn a commission at no extra cost to you.