Choosing the right stamping press is a critical decision for any industrial manufacturer. The process involves evaluating various factors to ensure that the selected press meets your specific production needs. In this guide, we will delve into the essential considerations to help you understand how to choose a stamping press effectively.

Understanding Stamping Presses

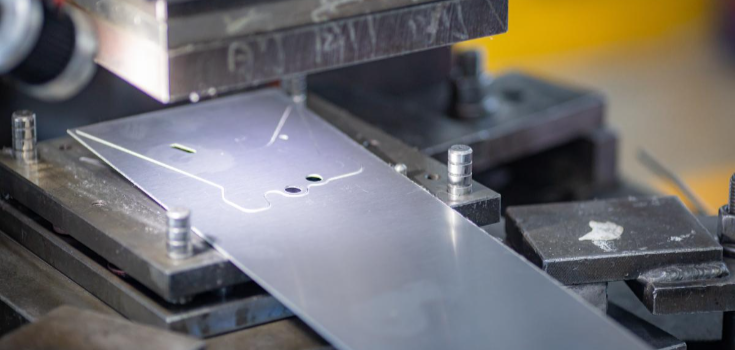

Stamping presses are machines used to shape or cut metal by deforming it with a die. They are integral to the manufacturing processes of many industries, including automotive, aerospace, and electronics.

Types of Stamping Presses

There are several types of stamping presses, each serving different purposes. Understanding their functions will aid in making an informed decision.

Mechanical Presses

Mechanical presses operate using a flywheel and crankshaft. They are known for their high speed and precision, making them suitable for high-volume production.

Hydraulic Presses

Hydraulic presses use a hydraulic cylinder to exert pressure. They provide consistent force and are ideal for deep drawing and other tasks requiring steady pressure.

Servo Presses

Servo presses offer flexibility and control, using a servo motor to drive the ram. They are efficient for operations requiring variable speeds and forces.

Key Factors to Consider

Production Requirements

Evaluate your production needs, including the type of materials you will be working with and the volume of production. This will determine the type and size of the press required.

Press Capacity

The capacity of a stamping press indicates the maximum force it can exert. It is crucial to select a press with sufficient capacity to handle the maximum thickness and material strength of your projects.

Die Size and Stroke Length

Consider the size of the dies you will be using and the stroke length required for your operations. This will impact the choice of press and its configuration.

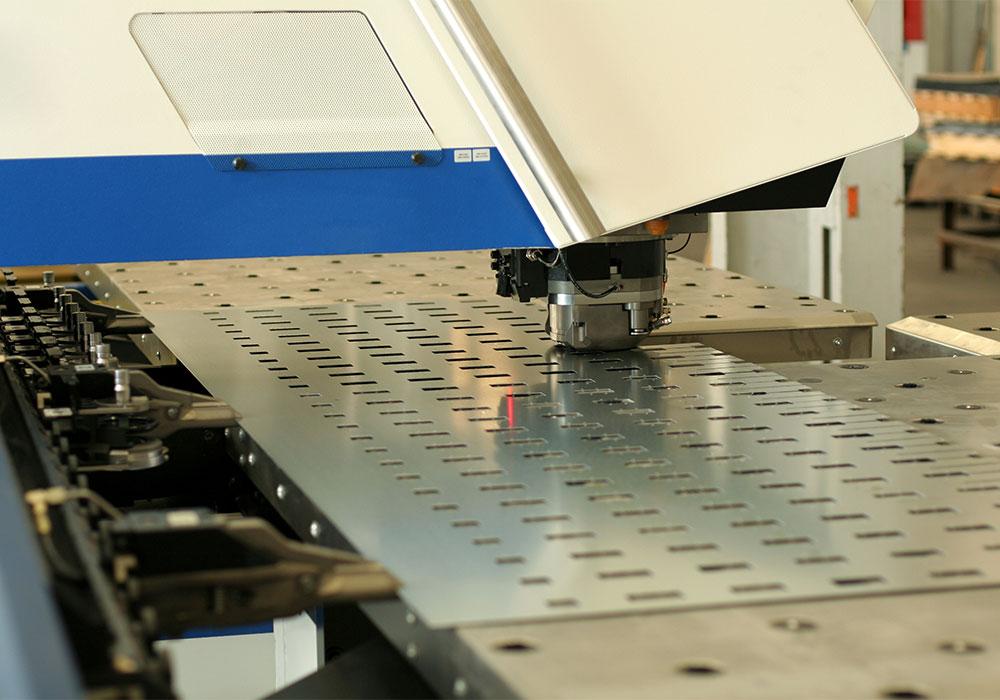

Automation and Integration

Modern stamping presses often come with automation features that can enhance productivity and reduce labor costs. Consider whether your operations will benefit from such integrations.

Safety Features

Ensure that the stamping press is equipped with necessary safety features to protect operators and maintain a safe working environment. For more on safety, visit our stamping press safety tips.

Evaluating Costs

Initial Investment

The cost of purchasing a stamping press can vary widely based on its type, capacity, and features. Balancing the initial investment with the expected return is essential.

Maintenance and Operating Costs

Consider the ongoing maintenance and operational costs associated with the press. A press with lower upfront costs might incur higher maintenance expenses.

Additional Considerations

Space and Infrastructure

Ensure that your facility can accommodate the size and power requirements of the chosen stamping press.

Supplier Reputation

Research potential suppliers to ensure they offer reliable support and service. A reputable supplier can provide valuable insights and assistance.

Future Expansion

Consider future production needs and whether the press can be upgraded or adapted to meet evolving demands.

Conclusion

Choosing the right stamping press involves careful consideration of various factors, from production needs and press capacity to costs and supplier reputation. By understanding these elements, you can make an informed decision that will enhance your manufacturing operations.

FAQs

What is the difference between mechanical and hydraulic presses?

Mechanical presses are faster and use flywheels, while hydraulic presses offer consistent force using hydraulic cylinders.

How important is press capacity?

Press capacity is crucial as it determines the maximum force the press can exert, impacting the thickness and strength of materials it can handle.

Can automation improve stamping press efficiency?

Yes, automation can significantly enhance efficiency by reducing manual labor and increasing precision in operations.

This article contains affiliate links. We may earn a commission at no extra cost to you.