Understanding how metal stamping machines work is crucial for anyone involved in industrial manufacturing. These machines play a vital role in the production of numerous everyday items, from car parts to kitchen appliances. In this guide, we will delve deep into the workings of these machines, providing a comprehensive overview tailored for an audience eager to learn more about the industrial processes that shape our world.

The Basics of Metal Stamping

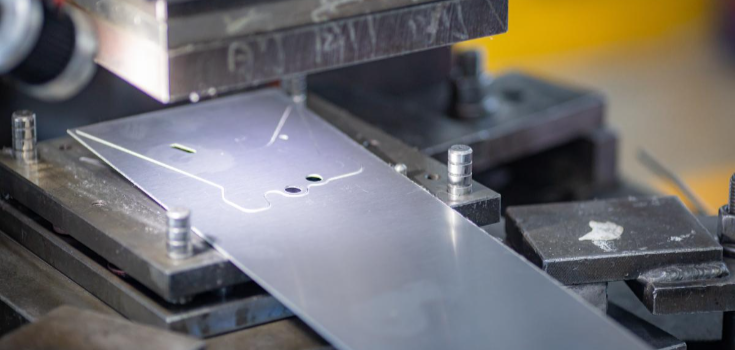

Metal stamping is a process that uses dies to transform flat metal sheets into specific shapes. It’s widely used in various industries due to its efficiency and cost-effectiveness. This process involves placing the metal sheet into a stamping press where a tool and die surface forms the metal into the desired shape. Understanding the basic principles of metal stamping can help grasp more complex concepts as we proceed.

Components of a Metal Stamping Machine

The Stamping Press

The heart of any stamping operation is the stamping press. This component applies force to the die, which shapes the metal. Stamping presses can be mechanical or hydraulic, each with its own advantages depending on the application.

The Die

The die consists of two parts: the punch and the die block. The punch pushes the metal into the die block, creating the desired shape. Dies are designed to be precise and durable, ensuring consistent results over time.

Feed System

The feed system is responsible for guiding the metal sheet through the machine. It ensures that the sheet is accurately positioned for each stamping operation, which is crucial for maintaining quality and efficiency.

How the Stamping Process Works

The stamping process begins with feeding a metal sheet into the press. Once the sheet is in place, the press applies force to the die, forming the metal into the desired shape. This process can be repeated multiple times to achieve complex shapes or additional features.

Types of Stamping Processes

Blanking

Blanking involves cutting the metal sheet into specific shapes. This is often the first step in the stamping process, preparing the sheet for further operations.

Bending

Bending shapes the metal by deforming it along a straight line. This process is used to create angles and curves in the material.

Embossing

Embossing is used to create raised or recessed designs on the metal surface, adding texture and visual interest.

Benefits of Metal Stamping

Metal stamping offers numerous benefits, including high production speed, consistent quality, and the ability to produce complex shapes. These advantages make it a popular choice for mass production in various industries.

Applications of Metal Stamping

Metal stamping is used in a wide range of applications, from automotive components to household appliances. Its versatility and efficiency make it an essential process in modern manufacturing.

Challenges in Metal Stamping

Despite its many benefits, metal stamping also presents challenges. These include tool wear, material waste, and the need for precise control over the process. Addressing these challenges requires careful planning and investment in quality equipment.

Advancements in Metal Stamping Technology

Recent advancements in technology have improved the efficiency and precision of metal stamping machines. Innovations such as computer-aided design (CAD) and automation have transformed the industry, allowing for more complex designs and faster production.

The Future of Metal Stamping

As technology continues to evolve, the future of metal stamping looks bright. Emerging trends such as 3D printing and smart manufacturing hold promise for further enhancing the capabilities of stamping machines.

FAQs

What materials can be used in metal stamping?

Metal stamping can be performed on a variety of materials, including steel, aluminum, and copper. The choice of material depends on the application and desired properties of the final product.

How does metal stamping differ from other metal forming processes?

Unlike processes such as forging or casting, metal stamping uses a die to shape the metal. This allows for high precision and repeatability, making it ideal for large-scale production.

What are the environmental impacts of metal stamping?

Metal stamping can generate waste material, but advancements in recycling and waste management have reduced its environmental impact. Additionally, the efficiency of the process helps minimize resource consumption.

For more information on the workings of metal stamping machines, check out this resource.

Explore more about metal mosaic projects and laser-cut metal art to see how these processes are applied creatively.

This article contains affiliate links. We may earn a commission at no extra cost to you.