The fascination with laser cutters lies in their precision and efficiency. If you’ve ever wondered how laser cutters work, you’re in the right place. This article will walk you through the mechanisms behind this innovative technology that’s revolutionizing industrial manufacturing.

Laser cutters have become indispensable in various industries, from cutting stainless steel to crafting intricate designs in materials. Understanding how they function can help manufacturers optimize their processes and reduce waste.

The Basics of Laser Cutting

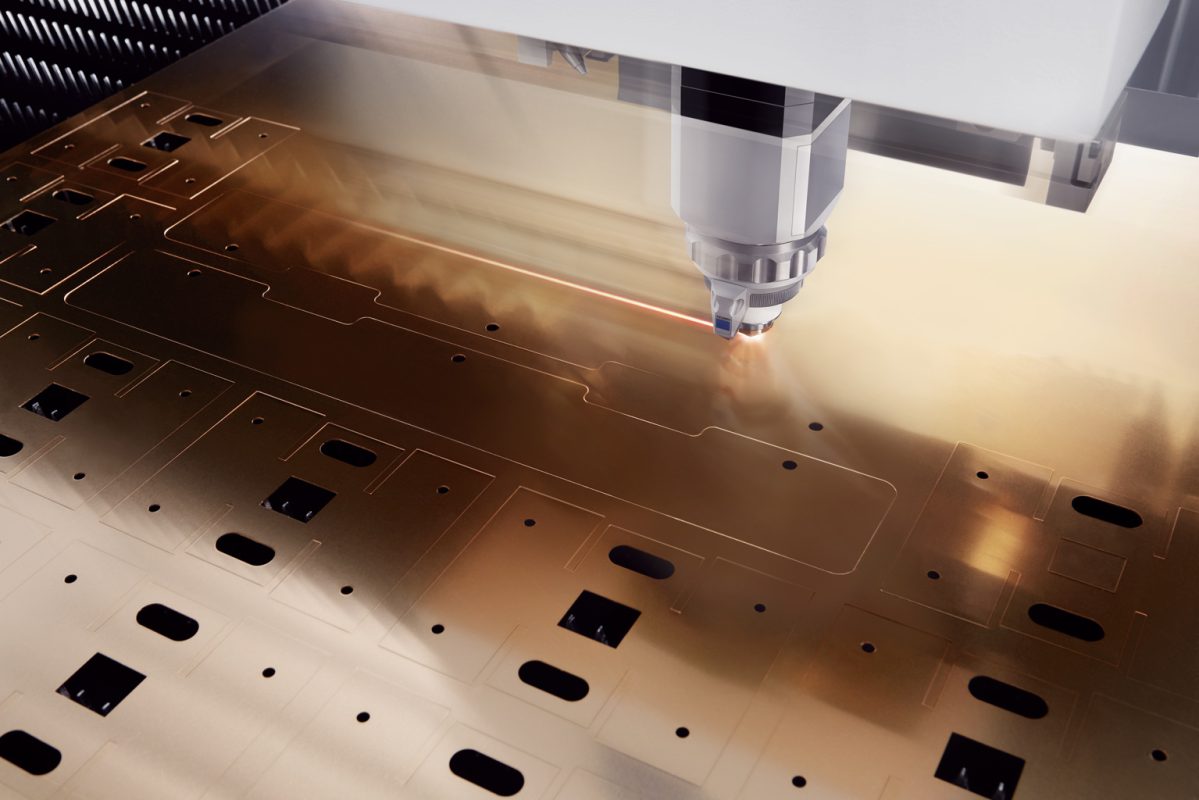

At its core, laser cutting utilizes a high-powered laser beam to slice through materials. The intense heat generated by the laser beam vaporizes or melts the material, allowing for precise cuts. But how do laser cutters manage such precision?

Generation of the Laser Beam

The process begins with the generation of a laser beam. The laser is amplified as it passes through a series of mirrors and lenses, focusing the energy into a narrow, intense beam capable of cutting through materials with pinpoint accuracy.

Control and Movement

The focused laser beam is directed onto a material through computer-controlled movements. These movements ensure that the laser cuts along the specified path, achieving complex shapes and designs. Automation in these systems allows for repetitive precision in mass production.

Types of Laser Cutters

Various laser cutting machines cater to different industrial needs. Let’s explore some of them:

CO2 Laser Cutters

Widely used for cutting, engraving, and boring, CO2 lasers are optimal for non-metal materials such as wood, glass, and plastics. They are popular due to their efficiency and versatility.

Fiber Laser Cutters

Fiber lasers are known for their speed and power. They excel in precision metal cutting and are often used in automotive and aerospace industries for cutting metals like steel and aluminum.

Crystal Laser Cutters

These cutters are ideal for very precise and detailed work. They use crystal mediums to produce the laser beam, and although they are powerful, they are also more expensive and have a shorter lifespan than other types.

Applications of Laser Cutting

Laser cutters are versatile tools in modern manufacturing. They can create intricate patterns and shapes that were once impossible with traditional methods. Here are some applications:

Metal Fabrication

Laser cutters are integral to CAD design for metal fabrication, allowing for precise cuts and intricate designs in metals ranging from steel to alloys.

Automotive Industry

In the automotive sector, laser cutters streamline the production of complex parts, enabling manufacturers to produce sophisticated components with reduced labor costs and increased precision.

Textile Industry

Laser cutters are used for cutting fabrics with high precision, ensuring patterns and designs are perfectly replicated. This increases efficiency and productivity in textile manufacturing.

Advantages of Laser Cutting

Laser cutting offers numerous benefits over traditional cutting methods. Some of these advantages include:

Precision and Accuracy

The precision of laser cutters is unmatched, allowing for intricate designs and minimal material wastage.

Speed and Efficiency

Laser cutters are faster than conventional methods, significantly reducing production times and enhancing throughput.

Cost-Effectiveness

By minimizing material waste and reducing labor costs, laser cutters offer cost-effective manufacturing solutions.

Challenges in Laser Cutting

While laser cutters bring numerous advantages, they also present challenges that manufacturers must navigate:

Material Limitations

Not all materials are suitable for laser cutting. Reflective materials can pose problems as they reflect the laser beam, reducing cutting efficiency.

Initial Setup Costs

The initial investment for laser cutting equipment can be high. However, this is often offset by long-term savings and efficiency gains.

The Future of Laser Cutting

As technology advances, so does the potential of laser cutting. Enhanced lasers and improved material compatibility could lead to even more efficient manufacturing processes. Future developments may include:

Integration with AI

Integrating AI with laser cutting could improve precision and reduce errors in automated systems, enabling smarter manufacturing techniques.

Eco-Friendly Processes

Innovations in laser technology could lead to reduced energy consumption and more sustainable manufacturing practices, aligning with global goals for environmental conservation.

Conclusion

The exploration of how laser cutters work underscores their pivotal role in modern manufacturing. From their humble beginnings to their cutting-edge applications today, laser cutters continue to shape industries with precision and efficiency. For those venturing into cutting aluminum with high accuracy or other materials, understanding these machines is crucial.

FAQ Section

What types of materials can be cut using laser cutters?

Laser cutters can cut a variety of materials including metals, plastics, textiles, and wood. The suitability depends on the type of laser used.

How does laser cutting differ from traditional cutting methods?

Laser cutting offers higher precision, speed, and efficiency compared to traditional methods. It allows for intricate designs and reduces material wastage.

What industries benefit most from laser cutting?

Industries such as automotive, aerospace, metal fabrication, and textiles benefit significantly from the precision and efficiency of laser cutting technology.

This article contains affiliate links. We may earn a commission at no extra cost to you.