In today’s competitive manufacturing landscape, the demand for high strength steel has surged due to its superior qualities, such as increased durability and reduced weight. However, while the benefits are numerous, the stamping challenges associated with this material can be daunting. Understanding these challenges is crucial for industrial manufacturers aiming to optimize their operations.

Introduction to High Strength Steel

High strength steel is a type of metal that offers enhanced strength and performance. It is widely used in automotive, construction, and various other industries. The key advantage of this material is its ability to maintain strength while being lighter, which contributes to efficiency in manufacturing and end-use applications.

Key Challenges in Stamping High Strength Steel

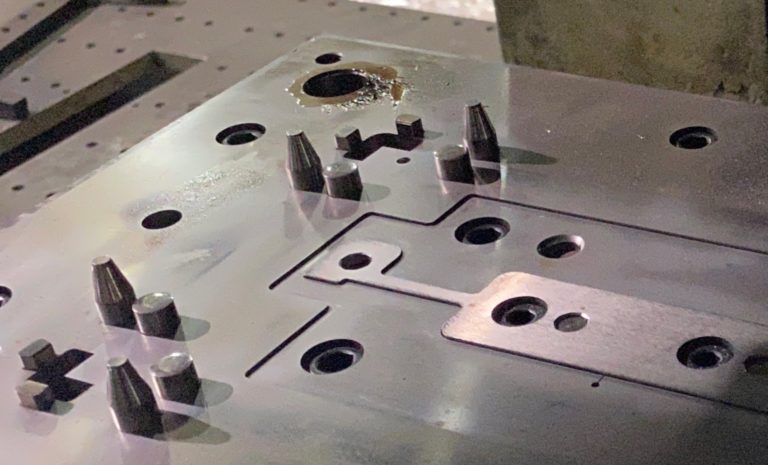

Tool Wear and Tear

One of the primary concerns in high strength steel stamping is the increased wear and tear on tools. The hardness of the material accelerates the degradation of stamping tools, necessitating frequent maintenance and replacement. This can lead to increased costs and downtime.

Springback Issues

Springback is a common issue when working with high strength steel. After the material is deformed in the stamping process, it tends to return to its original shape, which can affect the precision of the final product. Manufacturers must account for this behavior to ensure product accuracy.

Material Fracture

The risk of material fracture is higher with high strength steel due to its reduced ductility. This challenge requires manufacturers to carefully control the stamping process to prevent defects and ensure product quality.

Strategies for Overcoming Stamping Challenges

Advanced Tooling Solutions

To counteract tool wear, manufacturers are investing in advanced tooling materials and coatings. These innovations enhance the durability of tools, reducing the frequency of replacements and minimizing downtime. For insights on improving stamping productivity, you can explore this stamping productivity guide.

Accurate Springback Prediction

Utilizing advanced simulation software, manufacturers can more accurately predict springback effects. By simulating the stamping process, they can make necessary adjustments to the tooling and process parameters, ensuring that the final product meets design specifications.

Material Handling Techniques

Implementing precise material handling and lubrication techniques can reduce the risk of fracture. Proper lubrication minimizes friction during the stamping process, decreasing the likelihood of defects.

The Role of Technology in Addressing Stamping Challenges

Automation and Robotics

Automation plays a pivotal role in overcoming high strength steel stamping challenges. Robots can manage repetitive tasks with precision, reducing human error and enhancing efficiency. For more on how technology aids stamping operations, visit this stamping monitoring systems guide.

Data Analytics

Data analytics allows manufacturers to monitor and analyze the stamping process in real-time. By identifying patterns and anomalies, they can make informed decisions to optimize operations and prevent potential issues.

Innovative Press Designs

Modern press designs equipped with advanced features like vibration analysis can significantly enhance stamping efficiency. Learn more about these innovations in this vibration analysis article.

Future Trends in High Strength Steel Stamping

Eco-Friendly Approaches

As sustainability becomes a priority, manufacturers are exploring eco-friendly approaches to high strength steel stamping. This includes using sustainable materials and minimizing waste in the production process.

Collaborative Industry Efforts

Collaboration among industry players is crucial to address common challenges. By sharing knowledge and resources, manufacturers can develop innovative solutions to improve the stamping process.

Conclusion

While the challenges of high strength steel stamping are significant, they are not insurmountable. Through advanced technology, strategic planning, and industry collaboration, manufacturers can effectively navigate these challenges and continue to leverage the benefits of high strength steel in their operations.

FAQs

What is the main challenge in stamping high strength steel?

The primary challenge is the increased wear and tear on tools, which can lead to higher costs and downtime.

How can manufacturers reduce springback issues?

Manufacturers can use advanced simulation software to predict and compensate for springback effects during the stamping process.

What role does technology play in addressing stamping challenges?

Technology, including automation, data analytics, and innovative press designs, is essential for optimizing stamping operations and overcoming challenges.

This article contains affiliate links. We may earn a commission at no extra cost to you.