In the rapidly evolving world of manufacturing, efficiency and precision are paramount. One of the pivotal components of modern manufacturing is the use of high speed stamping presses. These machines are essential for industries that require the rapid production of metal parts with consistent accuracy and quality. By the end of this article, you’ll have a comprehensive understanding of how these presses work, their applications, and their benefits.

Understanding High Speed Stamping Presses

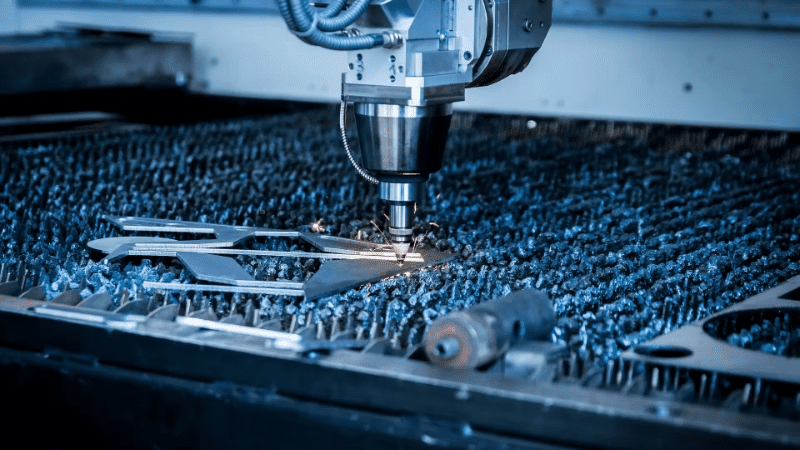

At the heart of many manufacturing operations lies the metal stamping process. High speed stamping presses are designed to perform this process faster and more efficiently than traditional methods. They utilize advanced technology to ensure precise and rapid stamping, making them indispensable in high-output environments.

How Do High Speed Stamping Presses Work?

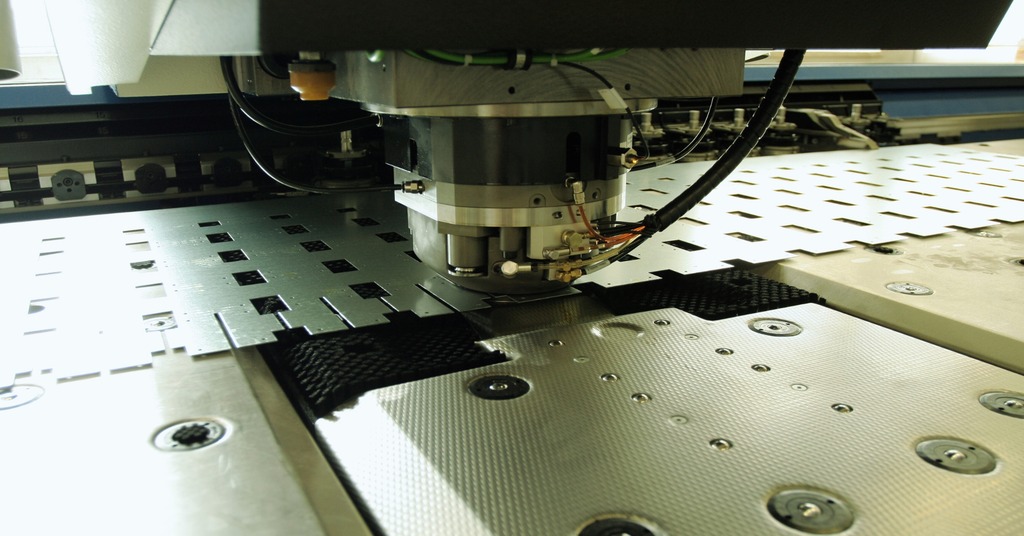

The operation of high speed stamping presses involves a series of coordinated movements that allow for the fast and accurate production of metal parts. The process begins with feeding a coil of metal into the press. The press then cuts, bends, and forms the metal into the desired shape using a series of dies and punches. The entire operation is automated, allowing for high-speed production without compromising on quality.

Key Components of High Speed Stamping Presses

Understanding the components of these presses is crucial for appreciating their functionality:

- Frame: Offers structural support and houses various components.

- Crankshaft: Converts rotational motion into linear motion.

- Flywheel: Stores energy to drive the press.

- Bed: Provides a stable surface for the workpiece.

- Slide: Moves up and down to exert force on the material.

Benefits of Using High Speed Stamping Presses

Industries that utilize high speed stamping presses enjoy numerous advantages:

- Increased Productivity: The ability to produce a large number of parts in a short time frame.

- Precision and Consistency: Ensures that every part is identical and meets stringent specifications.

- Cost Efficiency: Reduces labor costs and material waste.

- Versatility: Can be used for a wide range of materials and part designs.

Applications of High Speed Stamping Presses

These presses are used across various industries, including:

- Automotive: Manufacturing of car components.

- Electronics: Production of intricate parts for devices.

- Aerospace: Creation of lightweight and durable components.

- Consumer Goods: Fabrication of household items.

Challenges in Using High Speed Stamping Presses

While these presses offer many benefits, they also come with challenges such as:

- Initial Cost: High investment cost for setup and machinery.

- Maintenance: Requires regular maintenance to ensure optimal performance.

- Technical Expertise: Needs skilled operators and technicians.

Choosing the Right High Speed Stamping Press

Selecting the appropriate press involves considering factors such as production volume, material type, and budget. It’s important to work with a reputable supplier who can provide guidance tailored to your specific needs.

Future of High Speed Stamping Presses

The future of these presses looks promising, with advancements in technology continually enhancing their capabilities. Expect innovations in automation, energy efficiency, and precision, which will further solidify their role in modern manufacturing.

Conclusion

High speed stamping presses are integral to the success of many manufacturing operations. Their ability to produce high-quality parts quickly and efficiently makes them a valuable asset in any production environment. As industries continue to evolve, these presses will remain a cornerstone of manufacturing, driving progress and innovation.

FAQ

What industries benefit most from high speed stamping presses?

Industries such as automotive, electronics, aerospace, and consumer goods benefit greatly due to the need for high-volume and precise manufacturing.

How do high speed stamping presses improve efficiency?

By automating the production process, reducing waste, and ensuring precision, these presses significantly boost manufacturing efficiency.

What should be considered when purchasing a high speed stamping press?

Considerations include production needs, material compatibility, budget, and supplier reputation. Consulting with experts can also provide valuable insights.

This article contains affiliate links. We may earn a commission at no extra cost to you.