High-speed cutting is a term that resonates well within the manufacturing industry. It’s a technology that has brought significant advancements and numerous benefits to industrial processes. In today’s highly competitive market, the key to staying ahead lies in adopting efficient and innovative techniques. Let’s delve deeper into what makes high-speed cutting an indispensable asset for manufacturers.

The potential benefits of high-speed cutting are vast, ranging from improved precision to cost savings. As manufacturing firms seek ways to optimize their operations, understanding these benefits is crucial. In this article, we’ll explore the important aspects of high-speed cutting and how it can transform your manufacturing process.

What is High-Speed Cutting?

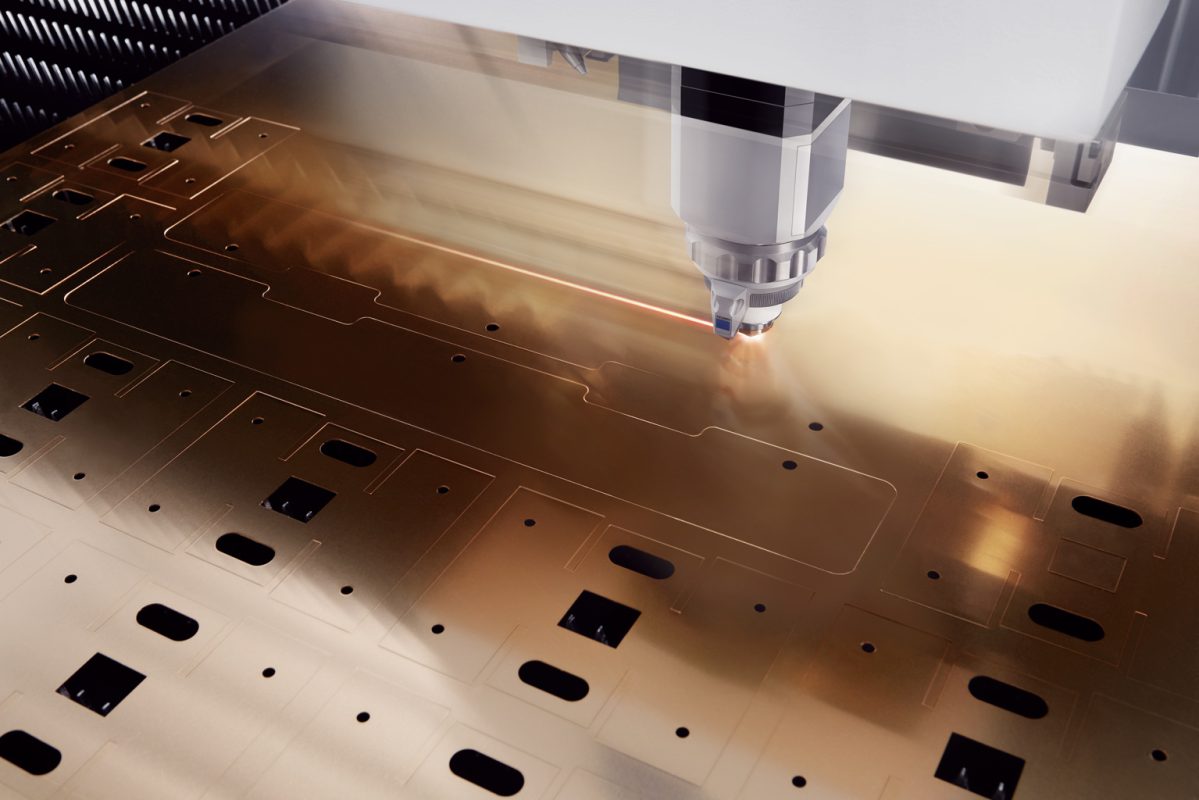

High-speed cutting refers to the process of machining workpieces at speeds significantly higher than traditional methods. This involves using advanced machinery and tools designed to handle increased speeds without compromising on precision.

The technology relies on cutting tools made from durable materials such as carbide or ceramics. These tools are capable of operating at high temperatures, making them ideal for rapid machining processes.

Advantages of High-Speed Cutting

There are numerous advantages of high-speed cutting which make it an attractive option for manufacturers. Here’s what you need to know:

Saves Time

One of the most appealing aspects of high-speed cutting is the time efficiency it offers. With quicker machining cycles, manufacturers can increase their output and meet production deadlines with ease.

Reduces Costs

Although the initial investment in high-speed cutting equipment may seem substantial, the long-term cost benefits are clear. Reduced energy consumption, less tool wear, and shorter cycle times all contribute to significant savings.

Enhances Precision

By employing high-speed cutting techniques, manufacturers can achieve unparalleled precision. This is essential in industries where accuracy is paramount, such as aerospace and automotive.

Improves Tool Life

The use of cutting-edge materials for tools ensures durability and longevity, even under high-speed conditions. This ultimately reduces the frequency of tool replacements.

Applications in the Manufacturing Industry

High-speed cutting is widely applicable in various sectors of the manufacturing industry:

Aerospace Industry

Precision and efficiency are crucial in the aerospace sector. High-speed cutting allows for the creation of intricate components with a high degree of accuracy.

Automotive Sector

The automotive industry benefits from high-speed cutting in the production of lightweight yet robust metal parts. This has become increasingly important with the push towards fuel-efficient vehicles.

Electronics Manufacturing

In electronics, where tiny, precise components are necessary, high-speed cutting plays a critical role in meeting these demanding standards.

Challenges of Implementing High-Speed Cutting

While the benefits of high-speed cutting are substantial, there are some challenges to consider:

Initial Costs

Investing in the necessary equipment can be expensive, especially for small to medium-sized enterprises looking to upgrade.

Training Requirements

Operators need thorough training to manage high-speed cutting machinery effectively, which can be both time-consuming and costly.

Maintenance Concerns

Keeping equipment in top condition requires more frequent maintenance due to the higher operational stresses involved.

Future of High-Speed Cutting

The future holds promising advancements for high-speed cutting. As technology continues to evolve, we can expect even faster and more precise processes that will redefine manufacturing standards.

For more on achieving precision in metal cutting, visit Precision Metal Cutting.

Comparing with Traditional Cutting Methods

Your understanding of high-speed cutting should include a comparison with traditional methods:

Efficiency

Compared to traditional methods, high-speed cutting drastically reduces cycle times.

Material Removal Rates

The rate of material removal is much faster with high-speed cutting techniques.

Surface Finish

High-speed cutting generally provides a superior surface finish, critical for certain applications.

The Role of Technology in High-Speed Cutting

Technological innovations are at the core of high-speed cutting, with CAD/CAM systems playing a vital role. To learn more about how computer-aided design impacts cutting, read our article on CAD Design for Precision Cutting.

Environmental Impact

Adopting high-speed cutting can lead to energy savings and reduced waste, contributing positively to environmental conservation efforts.

Discover more about efficient metal cutting methods at this external link.

FAQs About High-Speed Cutting

What industries benefit the most from high-speed cutting?

The aerospace, automotive, and electronics industries benefit significantly due to their need for precise and efficient component production.

Is high-speed cutting suitable for all types of materials?

While suitable for many materials, including metals and composites, certain materials may require specific cutting conditions.

What is the future outlook for high-speed cutting?

The future looks promising with continual advancements aimed at improving speed, efficiency, and precision in manufacturing processes.

This article contains affiliate links. We may earn a commission at no extra cost to you.