The world of manufacturing is ever-evolving, with global stamping equipment manufacturers playing a pivotal role in shaping the industry’s future. From automotive to consumer electronics, these manufacturers provide essential tools that drive productivity and efficiency across numerous sectors. Understanding their impact and the innovations they bring to the table is crucial for anyone involved in the industrial landscape.

The Importance of Stamping Equipment in Manufacturing

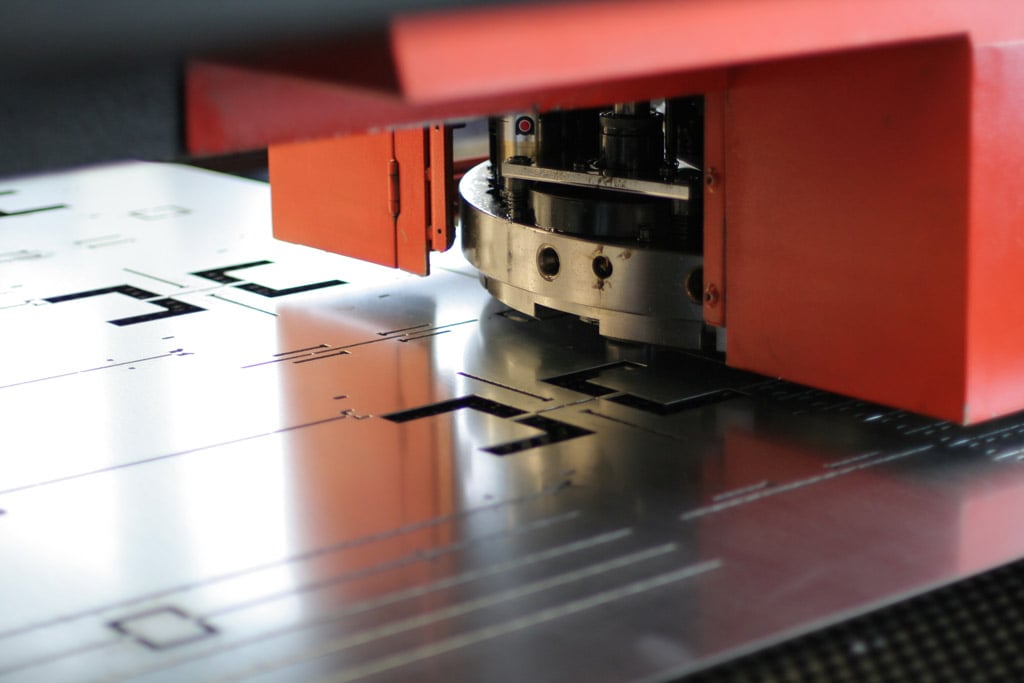

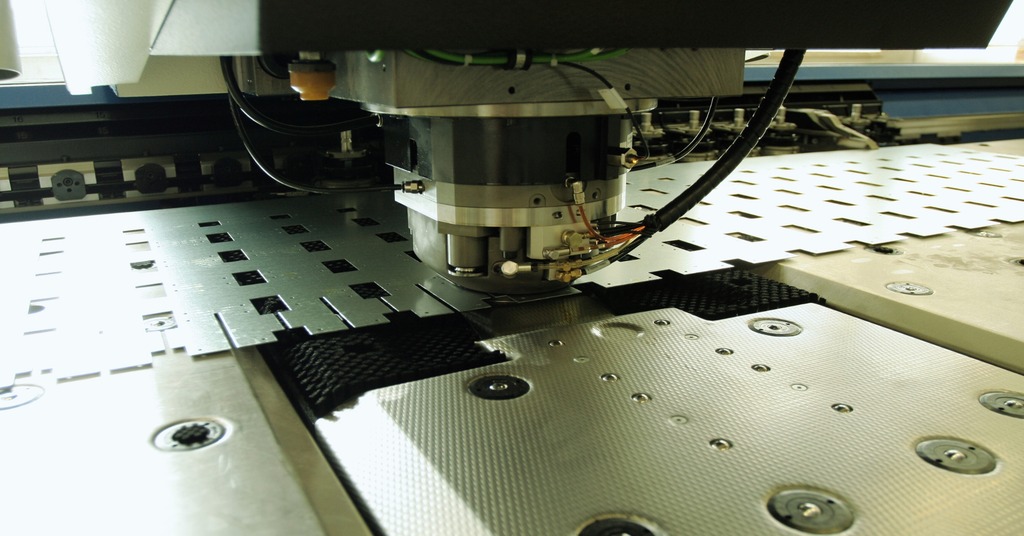

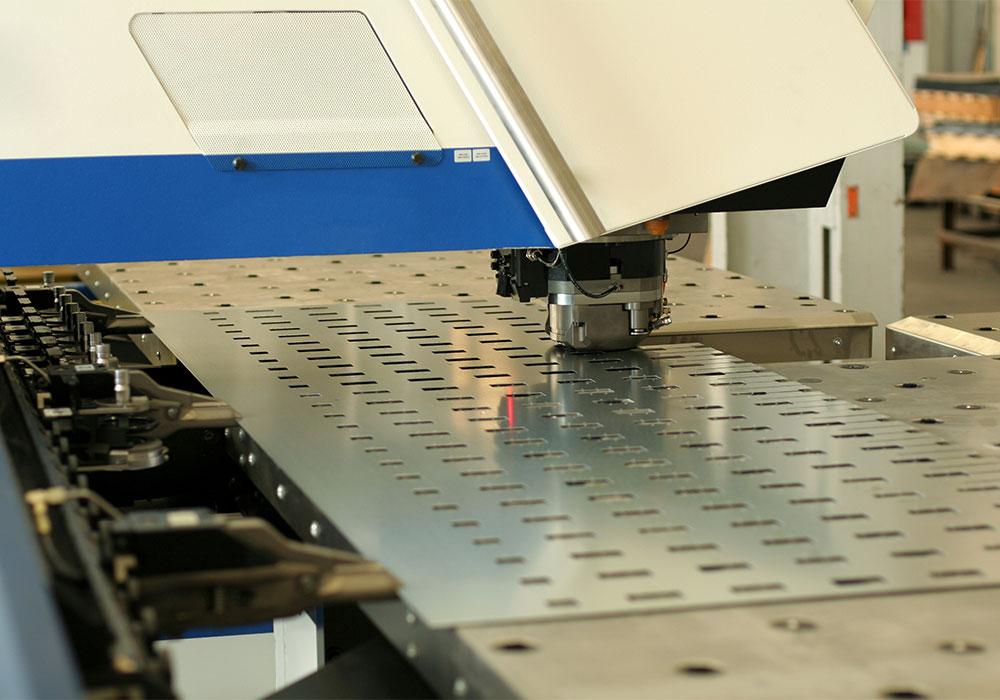

Stamping equipment is fundamental to the production processes in various industries. It allows manufacturers to efficiently shape and form metal sheets into desired components. This process is not only cost-effective but also ensures high precision and repeatability. With the rise of metal stamping technology, manufacturers can meet the increasing demand for complex and intricate parts.

Leading Global Stamping Equipment Manufacturers

The market for stamping equipment is vast, with numerous players offering a range of solutions. Key players include companies that specialize in providing cutting-edge technology and equipment that cater to both small-scale operations and large industrial plants. These manufacturers focus on innovation, quality, and customer satisfaction.

Innovation in Stamping Technology

Innovations in stamping technology have transformed the manufacturing landscape. From automation and robotics to advanced materials and processes, these developments have enhanced the efficiency and capabilities of stamping equipment. As manufacturers continue to invest in research and development, the industry sees a constant influx of new technologies that push the boundaries of what is possible.

Challenges Faced by Stamping Equipment Manufacturers

Despite the advancements, global stamping equipment manufacturers face several challenges. These include fluctuating raw material prices, the need for sustainable practices, and the continuous demand for technological advancements. Additionally, manufacturers must navigate the complexities of global trade and regulatory environments to remain competitive.

Applications of Stamping Equipment Across Industries

Stamping equipment finds applications across a wide range of industries, each with its unique requirements and challenges. For instance, the automotive industry relies heavily on stamping for producing body panels and components. Similarly, the electronics industry uses stamping to create precise parts for devices.

In the medical device sector, stamping is crucial for manufacturing components that meet stringent quality and safety standards. This diversity in applications highlights the versatility and importance of stamping equipment in modern manufacturing.

Quality Control in Stamping Production

Ensuring quality in stamping production is paramount. Manufacturers implement rigorous quality control measures to ensure that each component meets the required specifications and standards. This involves regular inspections, testing, and adherence to industry regulations.

For more insights on maintaining quality in stamping, visit our detailed guide on quality control in stamping.

Cost Considerations: New vs. Used Stamping Equipment

When investing in stamping equipment, manufacturers often face the decision between purchasing new or used machinery. Each option has its pros and cons. New equipment typically offers the latest technology and warranty benefits, while used equipment can be more cost-effective.

For a deeper understanding of this decision-making process, explore our comparison of used vs. new stamping equipment.

The Future of Global Stamping Equipment Manufacturers

The future looks promising for global stamping equipment manufacturers. With continued advancements in technology and a growing emphasis on sustainability, manufacturers are well-positioned to meet the evolving needs of the industry. As the world moves towards more automated and efficient production processes, stamping equipment will remain a cornerstone of manufacturing operations.

Training and Workforce Development

As technology evolves, the need for skilled operators becomes increasingly important. Manufacturers invest in training programs to ensure that their workforce is equipped with the necessary skills to operate advanced machinery. This not only enhances productivity but also ensures safety in the workplace.

Our resource on stamping machine operator training offers valuable insights into developing a skilled workforce.

Sustainability and Environmental Impact

As environmental concerns grow, manufacturers are adopting sustainable practices to reduce their carbon footprint. This includes using eco-friendly materials, implementing energy-efficient processes, and reducing waste. By prioritizing sustainability, manufacturers not only contribute to environmental conservation but also appeal to environmentally conscious consumers.

Conclusion

Global stamping equipment manufacturers play a crucial role in the industrial sector, driving innovation and efficiency across various industries. As they continue to face challenges and embrace new technologies, their contributions to the manufacturing world remain indispensable. By focusing on quality, sustainability, and workforce development, these manufacturers are well-equipped to lead the industry into a prosperous future.

Frequently Asked Questions

What are the key challenges for stamping equipment manufacturers?

Challenges include fluctuating raw material prices, the need for sustainable practices, and navigating global trade complexities.

Why is stamping equipment important in manufacturing?

Stamping equipment is essential for efficiently shaping metal sheets into components, ensuring precision and repeatability in production.

How are manufacturers addressing sustainability?

Manufacturers adopt eco-friendly materials, energy-efficient processes, and waste reduction strategies to minimize environmental impact.

This article contains affiliate links. We may earn a commission at no extra cost to you.