The future of metal stamping equipment is a topic of great interest and significance for industrial manufacturers. As technology advances, the landscape of metal stamping is evolving, bringing forth new opportunities and challenges. This article delves into the innovations and trends shaping the future of this critical manufacturing process.

Introduction to Metal Stamping Equipment

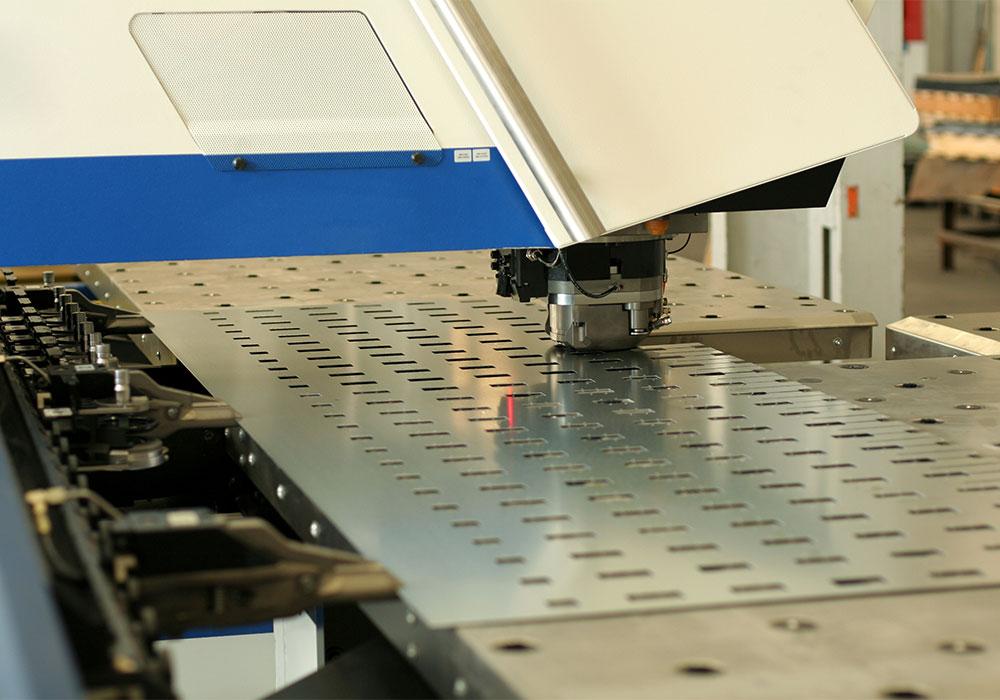

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a crucial component in the production of various industrial products, ranging from automotive parts to consumer electronics. With the growing demand for precise and efficient manufacturing processes, the future of metal stamping equipment is poised for significant advancements.

Technological Advancements in Metal Stamping

Automation and Robotics

The integration of automation and robotics in metal stamping is revolutionizing the industry. Automated systems enhance precision and reduce labor costs, leading to increased efficiency and productivity. Robotics plays a crucial role in handling complex stamping tasks, minimizing human error, and ensuring consistency in production.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming the way metal stamping processes are managed. AI-powered systems can analyze data to optimize stamping operations, predict maintenance needs, and improve overall equipment efficiency. This technology-driven approach is paving the way for smarter and more reliable metal stamping solutions.

Emerging Trends in Metal Stamping

Sustainable Manufacturing Practices

As environmental concerns gain prominence, sustainable manufacturing practices are becoming a priority in the metal stamping industry. Manufacturers are focusing on reducing waste, conserving energy, and using eco-friendly materials. This trend towards sustainability is not only beneficial for the environment but also enhances the reputation of businesses committed to green practices.

Customization and Flexibility

In response to increasing consumer demands, the future of metal stamping equipment is shifting towards greater customization and flexibility. Advanced technologies allow manufacturers to produce customized metal parts efficiently, catering to specific customer requirements. This flexibility in production is a key driver of growth in the industry.

Challenges and Solutions in Metal Stamping

Addressing Skill Gaps

One of the challenges facing the metal stamping industry is the shortage of skilled labor. To overcome this, companies are investing in training programs and apprenticeships to equip workers with the necessary skills. Operator Training is crucial for ensuring the efficient operation of modern stamping equipment.

Quality Control and Assurance

Maintaining high standards of quality is essential in metal stamping. Implementing robust Quality Control measures is vital for ensuring the reliability and precision of stamped metal parts. Manufacturers are leveraging advanced technologies to monitor and control quality throughout the production process.

Future Innovations in Metal Stamping

3D Printing and Additive Manufacturing

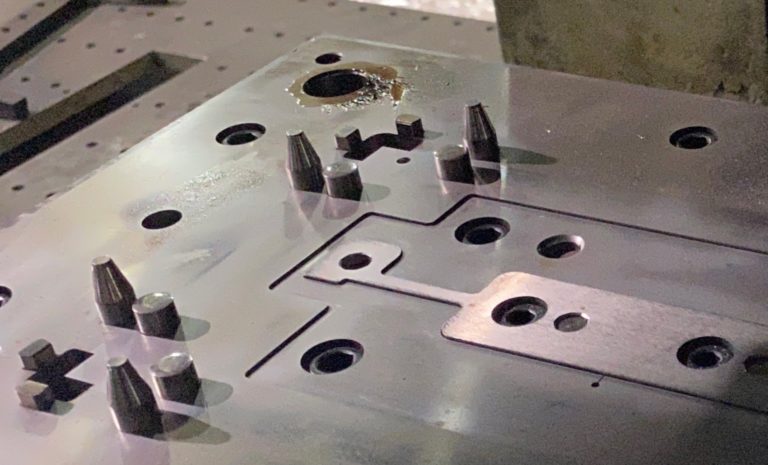

The integration of 3D printing and additive manufacturing is set to revolutionize metal stamping. These technologies enable the creation of complex geometries and prototypes, reducing lead times and costs. By combining traditional stamping methods with additive manufacturing, manufacturers can achieve greater design flexibility and innovation.

Internet of Things (IoT) and Connectivity

The Internet of Things (IoT) is playing a significant role in the future of metal stamping equipment. IoT-enabled devices provide real-time data on equipment performance, allowing for predictive maintenance and optimization of production processes. This connectivity enhances operational efficiency and reduces downtime.

Conclusion

The future of metal stamping equipment is bright, driven by technological advancements and emerging trends. Automation, AI, sustainability, and customization are shaping the industry, offering new possibilities for manufacturers. By embracing these innovations, the metal stamping industry is poised for growth and transformation.

FAQs

What is metal stamping?

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes using dies and presses.

How does automation impact metal stamping?

Automation enhances precision, reduces labor costs, and improves efficiency in metal stamping, leading to increased productivity.

What are the benefits of sustainable manufacturing in metal stamping?

Sustainable manufacturing reduces waste, conserves energy, and enhances the reputation of businesses committed to eco-friendly practices.

For more information on how metal stamping equipment works, you can check this external resource.

This article contains affiliate links. We may earn a commission at no extra cost to you.