Fiber laser cutting explained is a topic of growing interest in the realm of industrial manufacturing. As technology advances, the need for more precise and efficient cutting methods has become essential. In this article, we will delve into the intricacies of fiber laser cutting, shedding light on what makes it a preferred choice for many manufacturers.

What is Fiber Laser Cutting?

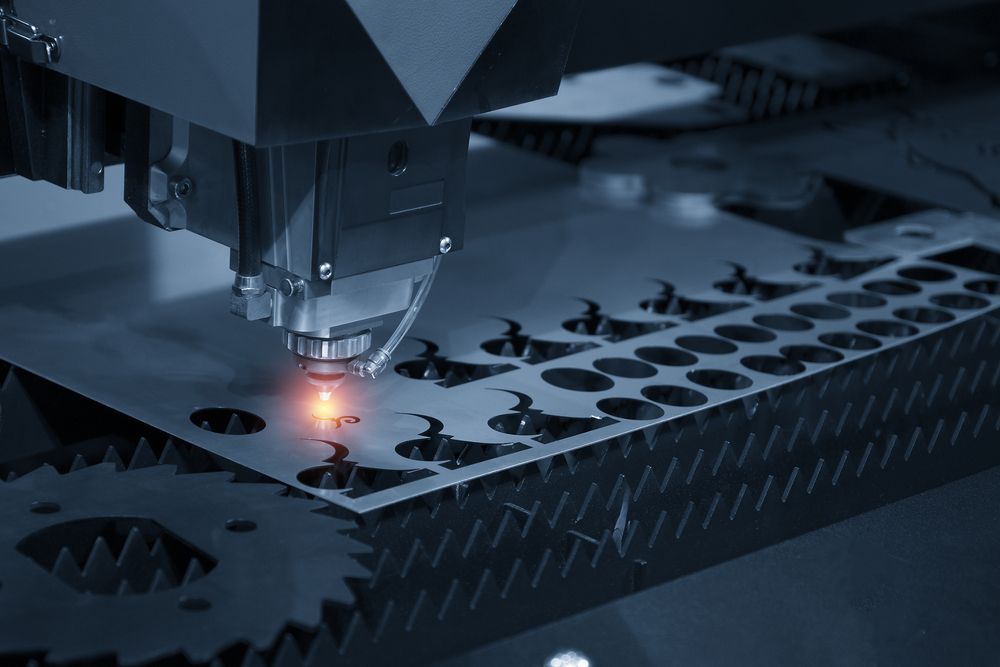

Fiber laser cutting is a technique that uses a high-powered laser beam to cut through various materials with precision. Unlike traditional cutting methods, fiber lasers offer unparalleled accuracy and speed, making them ideal for industrial applications.

How Does Fiber Laser Cutting Work?

At its core, fiber laser cutting involves directing a concentrated beam of light onto a material. The intense heat generated by the laser melts the material, allowing for highly accurate cuts. This process is controlled via computer systems, ensuring precision and consistency.

The Science Behind Fiber Lasers

The magic of fiber laser cutting lies in its use of fiber optics. Fiber lasers are distinct from CO2 lasers as they utilize optical fiber doped with rare elements like erbium and ytterbium. This setup allows for a more concentrated and efficient beam of light, making fiber lasers both powerful and energy-efficient.

The Process of Fiber Laser Cutting

Using a CNC system, the path of the laser is meticulously programmed. As the laser moves, it cuts through the material, guided by precise instructions from the computer. This allows for intricate designs and complex shapes to be cut with ease.

Advantages of Fiber Laser Cutting

Precision and Accuracy

One of the standout features of fiber laser cutting is its exceptional precision. With the capacity to produce intricate cuts with minimal effort, fiber lasers are a go-to choice for manufacturers aiming for high accuracy.

Speed and Efficiency

Fiber lasers cut faster than traditional methods, reducing production time and increasing overall efficiency. This speed does not compromise quality, ensuring that each cut meets the highest standards.

Material Versatility

Fiber laser cutting is not limited to metals. It can efficiently cut through materials like plastics, composites, and even wood, making it versatile for various industrial applications.

Applications of Fiber Laser Cutting

The applications of fiber laser cutting in industry are vast. From precision cutting in aerospace sectors to crafting intricate designs in jewelry making, its versatility is unmatched.

Aerospace Industry

In aerospace, the need for precision is paramount. Fiber laser cutting ensures components are manufactured to the highest standards, guaranteeing safety and performance.

Automotive Manufacturing

Automotive industries also benefit from fiber laser technology. It allows for fast production of car parts, reducing lead times and costs while ensuring exceptional quality.

Medical Equipment

The demand for high-precision tools and parts in medical technology is met by fiber lasers, ensuring components are both precise and reliable.

Challenges and Considerations

Initial Investment

While fiber laser cutting offers numerous benefits, the initial setup cost can be significant. However, the long-term savings and efficiency often justify this expense for many manufacturers.

Material Limitations

Although fiber lasers can cut a wide variety of materials, certain types may not be suitable, requiring alternative cutting methods like waterjet cutting.

Comparing Fiber Lasers with Other Cutting Technologies

Understanding how fiber lasers stack up against other technologies such as CO2 and plasma cutting is crucial in determining the best method for specific applications. Each has its own set of advantages and potential drawbacks.

Fiber vs. CO2 Lasers

While CO2 lasers have long been a staple in manufacturing, fiber lasers offer increased efficiency and lower maintenance needs.

Fiber Lasers vs. Plasma Cutting

Plasma cutting is excellent for thick materials but lacks the precision and versatility of fiber laser technology.

Looking Towards the Future

The future of fiber laser cutting is promising, with ongoing innovations set to improve efficiency and capabilities. As technology evolves, fiber lasers are poised to become even more integral to manufacturing processes.

FAQs About Fiber Laser Cutting

What materials can fiber lasers cut?

Fiber lasers can cut metals, plastics, composites, and more, offering versatility for various industries.

Is fiber laser cutting cost-effective?

Despite high initial costs, fiber laser cutting is cost-effective over time due to its efficiency and precision.

How is fiber laser cutting used in the automotive industry?

It’s used for fast, precise production of vehicle parts, reducing production time and costs while maintaining quality.

For further insights into precision cutting technologies, visit Metal Cutting.

This article contains affiliate links. We may earn a commission at no extra cost to you.