In the ever-evolving world of industrial manufacturing, the drive towards sustainability and cost-effectiveness has never been more critical. At the forefront of this movement is the adoption of energy efficient stamping presses. These machines are revolutionizing the industry by reducing energy consumption and minimizing costs, all while maintaining high levels of productivity.

Understanding the importance of energy efficient stamping presses is essential for manufacturers who are looking to stay competitive in todays market. By investing in these technologies, companies can significantly lower their energy bills and reduce their environmental impact.

What Are Energy Efficient Stamping Presses?

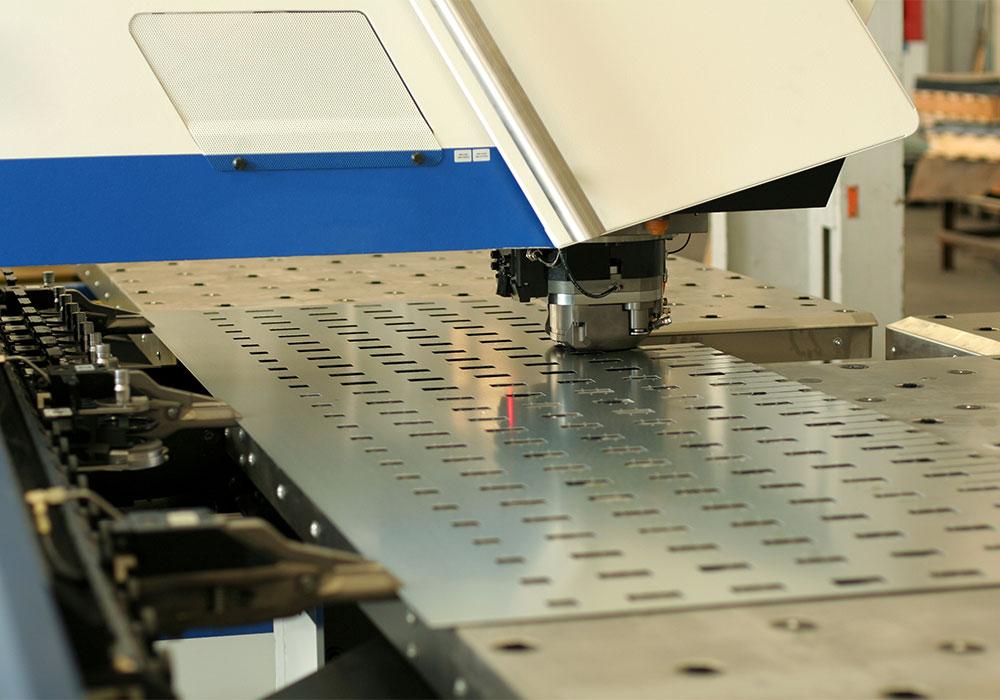

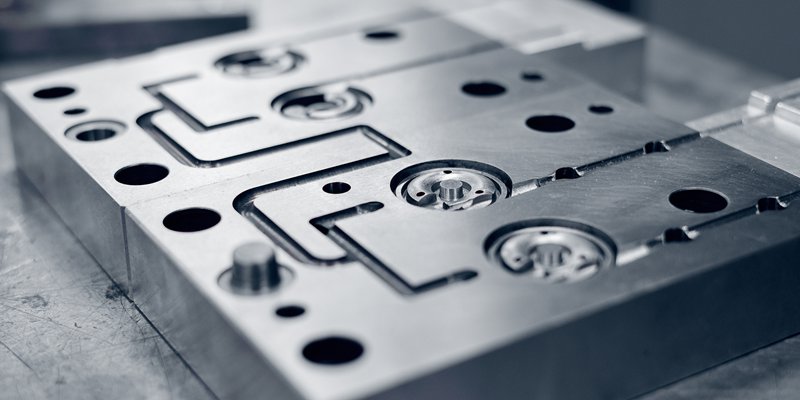

Energy efficient stamping presses are designed to consume less energy during the metal stamping process. Traditional stamping presses often require a significant amount of energy to operate, which can be costly and environmentally damaging. These modern machines incorporate advanced technologies that optimize energy usage without compromising on performance.

Components and Functionality

The key components of an energy efficient stamping press include advanced motor systems, energy recovery units, and precision control systems. These features work together to ensure that the press operates at optimal efficiency, using only the necessary amount of energy for each operation.

Benefits of Using Energy Efficient Stamping Presses

The advantages of using energy efficient stamping presses extend beyond just energy savings. These machines offer numerous benefits that can enhance the overall productivity and sustainability of a manufacturing operation.

Cost Savings

One of the most significant benefits is the potential for cost savings. By reducing energy consumption, manufacturers can lower their operational costs significantly. Over time, these savings can lead to a substantial return on investment, making energy efficient stamping presses a financially sound choice.

Environmental Impact

Reducing energy consumption also means a smaller carbon footprint. Energy-efficient technologies contribute to a more sustainable manufacturing process, aligning with global efforts to combat climate change. Manufacturers can enhance their reputation by demonstrating a commitment to environmental responsibility.

Technological Advancements in Stamping Presses

The development of energy efficient stamping presses has been made possible by advancements in technology. These innovations have enabled manufacturers to achieve higher levels of efficiency and precision than ever before.

Innovative Motor Systems

Modern stamping presses are equipped with high-efficiency motors that deliver optimal performance with minimal energy usage. These motors are designed to adjust their speed and torque based on the specific requirements of each task, ensuring that no energy is wasted.

Energy Recovery Units

Energy recovery units are another critical component of energy efficient stamping presses. These units capture and reuse energy that would otherwise be lost during the stamping process, further reducing energy consumption and operational costs.

Implementing Energy Efficient Stamping Presses in Manufacturing

For manufacturers looking to implement energy efficient stamping presses, careful planning and consideration are essential. The transition to these advanced machines requires an understanding of the technology and its integration into existing production lines.

Assessing Current Systems

The first step in implementing energy efficient stamping presses is to assess current systems and identify areas where improvements can be made. This involves evaluating energy usage, production efficiency, and potential areas for cost savings.

Training and Development

Investing in training and development is crucial for a successful transition. Operators and technicians must be adequately trained to use the new equipment and understand its benefits. This ensures that the machines are used to their full potential, maximizing the return on investment.

Case Studies: Success Stories in Energy Efficiency

Many manufacturers have successfully integrated energy efficient stamping presses into their operations, achieving significant benefits in terms of cost savings and environmental impact. These case studies provide valuable insights for other companies considering a similar transition.

Case Study 1: Automotive Industry

An automotive manufacturer implemented energy efficient stamping presses in their production line, resulting in a 30% reduction in energy consumption. This not only reduced operational costs but also enhanced the companys reputation for sustainability.

Case Study 2: Electronics Manufacturing

In the electronics manufacturing industry, a company adopted energy efficient stamping presses and saw a 25% decrease in energy usage. This allowed them to reinvest savings into other areas of the business, driving further growth and innovation.

Challenges and Considerations

While the benefits of energy efficient stamping presses are clear, there are challenges that manufacturers must consider. Understanding these challenges is essential for a smooth transition and successful implementation.

Initial Investment Costs

The initial cost of purchasing and installing energy efficient stamping presses can be significant. However, the long-term savings and benefits often outweigh these costs, making it a worthwhile investment for many companies.

Integration with Existing Systems

Integrating new technologies into existing systems can be complex. Manufacturers must ensure that energy efficient stamping presses are compatible with current production processes and that any necessary modifications are made.

The Future of Energy Efficient Stamping Presses

The future of energy efficient stamping presses is promising, with ongoing advancements in technology expected to drive further improvements in efficiency and performance. As the demand for sustainable manufacturing practices continues to grow, these machines will play an increasingly important role in the industry.

Emerging Technologies

Emerging technologies, such as the Internet of Things (IoT) and artificial intelligence, are expected to enhance the capabilities of energy efficient stamping presses. These innovations will enable even greater levels of precision and efficiency, further reducing energy consumption and costs.

Global Trends

Global trends towards sustainability and environmental responsibility will continue to drive the adoption of energy efficient stamping presses. Manufacturers who embrace these trends will be well-positioned to succeed in the competitive global market.

Conclusion

Energy efficient stamping presses represent a significant opportunity for industrial manufacturers to reduce costs, enhance productivity, and contribute to a more sustainable future. By understanding the benefits and challenges associated with these technologies, companies can make informed decisions and drive positive change within their operations.

Further Reading

For more information on the stamping process, you can visit this blog on sheet metal stamping process.

FAQ

- Q: What is an energy efficient stamping press?

A: An energy efficient stamping press is a machine designed to perform metal stamping with reduced energy consumption, utilizing advanced technologies to optimize performance. - Q: How do energy efficient stamping presses reduce costs?

A: These presses reduce costs by lowering energy consumption, which in turn decreases operational expenses and leads to long-term financial savings. - Q: Are energy efficient stamping presses environmentally friendly?

A: Yes, they are environmentally friendly as they reduce energy usage and contribute to a smaller carbon footprint, aligning with global sustainability efforts.

This article contains affiliate links. We may earn a commission at no extra cost to you.