In today’s world, where environmental concerns are at the forefront, adopting eco friendly stamping practices is becoming increasingly important. For industrial manufacturers, this shift not only helps in creating a sustainable future but also enhances business efficiency and profitability. Implementing such practices can significantly reduce the carbon footprint of manufacturing operations, leading to a positive impact on the environment.

Industrial manufacturers are constantly seeking ways to improve their processes. By integrating eco friendly stamping practices, they stand to gain numerous benefits, including cost savings, improved product quality, and enhanced brand reputation. In this article, we will delve into the various aspects of these practices and explore how they can be effectively implemented in the stamping industry.

Understanding Eco Friendly Stamping

Eco friendly stamping involves the use of techniques and materials that minimize environmental impact. This includes reducing waste, conserving energy, and using sustainable materials. By focusing on these key areas, manufacturers can align their operations with environmental goals and meet regulatory requirements.

Why Eco Friendly Practices Matter

Implementing eco friendly practices in stamping is crucial for several reasons. Firstly, it helps in reducing environmental pollution. Secondly, it leads to cost savings by optimizing resource usage. Thirdly, it enhances the safety and health of the workplace, ensuring a better environment for workers.

Steps to Implement Eco Friendly Stamping

There are several steps manufacturers can take to implement eco friendly stamping practices. These include adopting energy-efficient machinery, using recycled materials, and optimizing production processes. By focusing on these areas, manufacturers can achieve significant improvements in sustainability.

Energy Efficient Machinery

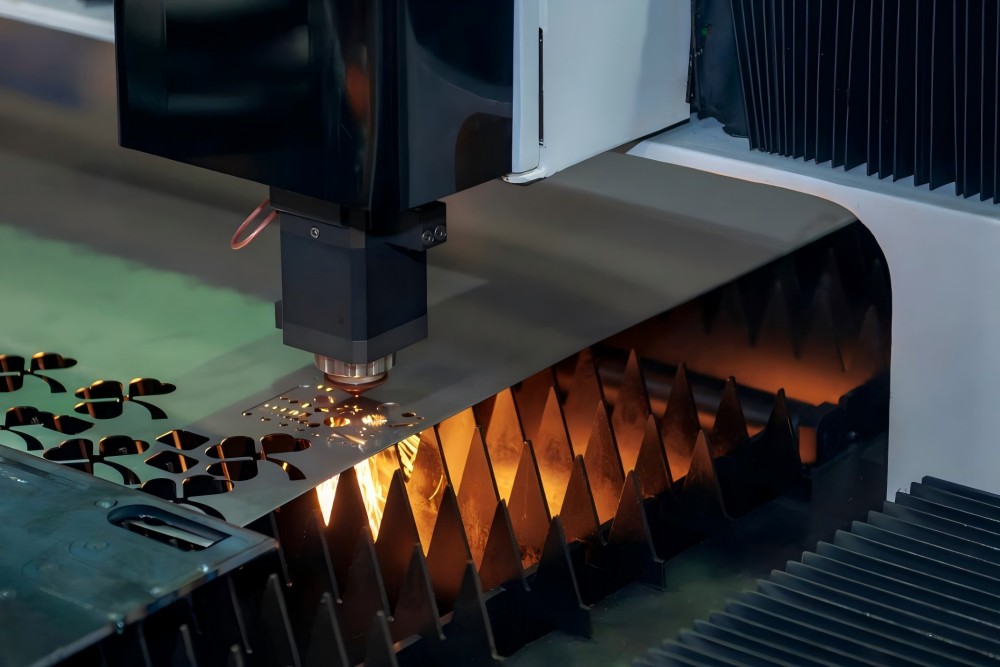

One of the primary ways to achieve eco friendly stamping is by using energy-efficient machinery. Modern stamping presses are designed to consume less energy while maintaining high performance. By investing in such equipment, manufacturers can reduce their energy consumption and lower their carbon footprint.

Benefits of Energy Efficiency

Energy-efficient machinery not only reduces environmental impact but also leads to cost savings. By lowering energy consumption, manufacturers can significantly reduce their operational costs. Additionally, energy-efficient equipment often requires less maintenance, further reducing costs.

Using Recycled Materials

Another important aspect of eco friendly stamping is the use of recycled materials. By using materials that have been recycled, manufacturers can reduce waste and conserve natural resources. This practice aligns with the principles of a circular economy, where materials are reused and recycled to minimize waste.

Advantages of Recycled Materials

Using recycled materials offers several benefits. It reduces the demand for raw materials, conserves energy, and decreases greenhouse gas emissions. Additionally, it supports the development of a sustainable supply chain, contributing to overall environmental goals.

Optimizing Production Processes

Optimizing production processes is another key component of eco friendly stamping. By streamlining operations and reducing waste, manufacturers can improve efficiency and reduce their environmental impact. This involves adopting lean manufacturing principles and using advanced technologies to monitor and control processes.

Implementing Lean Manufacturing

Lean manufacturing focuses on eliminating waste and optimizing efficiency. By identifying and eliminating non-value-added activities, manufacturers can reduce waste and improve productivity. This approach not only benefits the environment but also enhances the overall performance of the business.

Adopting Advanced Technologies

Advanced technologies, such as automation and data analytics, play a crucial role in eco friendly stamping practices. These technologies enable manufacturers to monitor operations in real-time, identify inefficiencies, and implement corrective measures.

Role of Automation

Automation helps in reducing human error and improving precision in stamping operations. By automating repetitive tasks, manufacturers can increase efficiency and reduce waste. Additionally, automation can lead to significant energy savings, contributing to environmental goals.

Training and Education

Training and education are essential components of implementing eco friendly stamping practices. By educating employees about the importance of sustainability, manufacturers can foster a culture of environmental responsibility within their organization.

Creating Awareness

Creating awareness about the benefits of eco friendly practices is crucial for successful implementation. By conducting workshops and training sessions, manufacturers can equip their employees with the knowledge and skills needed to adopt sustainable practices.

Monitoring and Evaluation

Continuous monitoring and evaluation are necessary to ensure the effectiveness of eco friendly stamping practices. By regularly assessing performance and making necessary adjustments, manufacturers can achieve continuous improvement in sustainability.

Using Data Analytics

Data analytics tools can provide valuable insights into the performance of stamping operations. By analyzing data, manufacturers can identify areas for improvement and implement strategies to enhance sustainability.

Collaboration and Partnerships

Collaboration and partnerships with other organizations can help manufacturers achieve their sustainability goals. By working together, companies can share best practices, resources, and knowledge, leading to better outcomes for the environment.

Building a Sustainable Supply Chain

Building a sustainable supply chain is essential for achieving eco friendly stamping. By collaborating with suppliers and partners, manufacturers can ensure that their entire supply chain adheres to sustainable practices.

Conclusion

In conclusion, adopting eco friendly stamping practices is not only beneficial for the environment but also for industrial manufacturers. By focusing on energy efficiency, using recycled materials, optimizing production processes, and embracing advanced technologies, manufacturers can achieve sustainability while enhancing their business performance. The journey towards a greener future requires commitment and collaboration, but the rewards are well worth the effort.

FAQs

What are the benefits of eco friendly stamping?

The benefits include reduced environmental impact, cost savings, improved product quality, enhanced brand reputation, and compliance with regulatory requirements.

How can manufacturers implement eco friendly stamping practices?

Manufacturers can implement these practices by using energy-efficient machinery, recycled materials, optimizing production processes, and adopting advanced technologies.

Why is training important for eco friendly stamping?

Training is important because it creates awareness about the benefits of sustainability and equips employees with the knowledge and skills needed to adopt eco friendly practices.

This article contains affiliate links. We may earn a commission at no extra cost to you.