The world of DIY precision metal cutting is vast and fascinating, especially for those with an inclination towards industrial manufacturing or metal crafting. Understanding the intricacies of metal cutting can provide a significant advantage not only in professional settings but also in DIY projects. With the right tools and techniques, achieving high levels of precision is possible for anyone willing to learn.

Understanding the Basics of Metal Cutting

At the core, metal cutting involves removing material from a workpiece to shape it into the desired form. While it may sound straightforward, achieving precision requires a blend of the right equipment, materials, and understanding of metal properties.

The Importance of Precision in Metal Cutting

Precision in metal cutting ensures that components fit together correctly, which is critical in applications where exact dimensions and fit are vital. Poor precision can lead to material wastage, defective products, and increased costs.

Essential Tools for DIY Metal Cutting

1. Cutting Tools

There are various tools like saws, lasers, and plasma cutters available for DIY metal cutting. Each tool has unique advantages depending on the type of metal and the precision required.

2. Measurement Tools

Accurate measurement is foundational in achieving precision. Tools such as calipers and protractors help ensure measurements are exact before cutting begins.

Understanding Metal Types

Different metals require distinct approaches. For instance, cutting aluminum requires different settings and methods compared to cutting steel. Understanding each metal’s properties is crucial for precision.

Techniques in Precision Metal Cutting

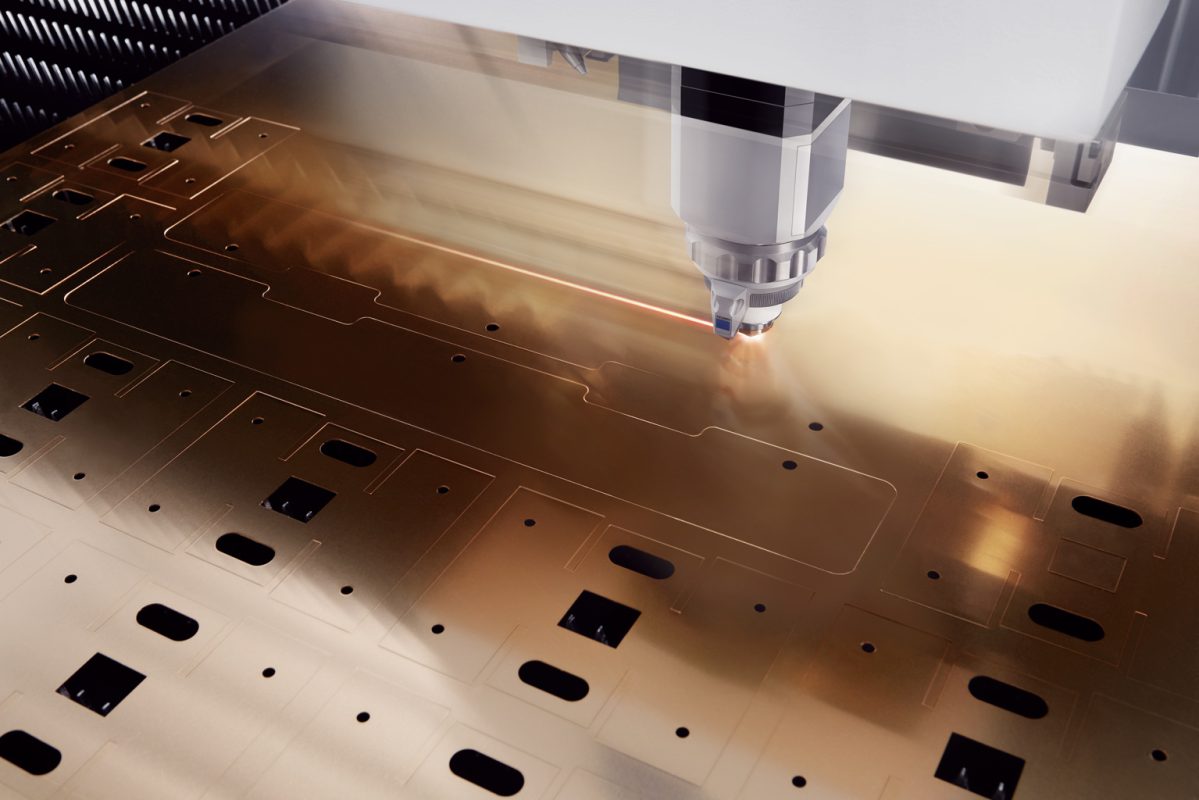

Laser Cutting

Laser cutting provides high precision and is suitable for various metals. It involves using a focused laser beam to melt and vaporize metal in a specific area. Explore modern methods for further insights.

Plasma Cutting

Plasma cutting is suitable for thick metal plates. It involves using a high-velocity jet of ionized gas to cut through metal.

Safety Tips for Metal Cutting

Safety is paramount in any metal cutting project. Protective gear such as gloves and goggles should always be worn. You can read more on metalwork safety tips on our website.

Common Mistakes to Avoid

One common mistake in DIY precision metal cutting is not accounting for material expansion during cutting. Always allow for a margin of error to ensure precise outcomes.

Benefits of DIY Precision Metal Cutting

Cutting metal on your own allows for flexibility in design and immediate feedback and iteration, which can be particularly beneficial for custom projects.

Incorporating CAD Designs

Using CAD (Computer-Aided Design) can significantly enhance precision by allowing detailed specifications and simulations prior to cutting. Learn more about integrating CAD at our CAD design guide.

Conclusion

DIY precision metal cutting opens up new possibilities for creativity and innovation. Whether in a professional or personal capacity, mastering metal cutting skills is empowering, allowing for precise, customized creations.

FAQs on DIY Precision Metal Cutting

What is the most suitable metal for cutting at home?

Aluminum is often recommended due to its lightness and ease of cutting compared to other metals.

Do I need a professional workshop for metal cutting?

No, with the right tools and resources, DIY enthusiasts can achieve precision at home.

Is laser cutting better than plasma cutting?

Both have their merits. Laser cutting offers higher precision, whereas plasma cutting can handle thicker materials.

This article contains affiliate links. We may earn a commission at no extra cost to you.