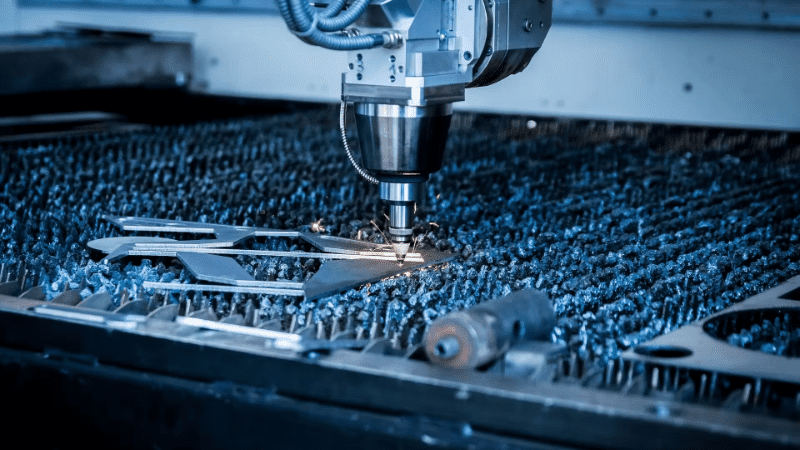

In today’s rapidly evolving industrial landscape, the concept of a digital twin in stamping press operations is gaining significant traction. This innovative approach is revolutionizing the way manufacturers operate, enabling increased efficiency, precision, and productivity. But what exactly is a digital twin, and how can it be applied to stamping press operations?

What is a Digital Twin?

A digital twin is a virtual replica of a physical entity or system. It serves as a bridge between the physical and digital worlds, allowing for real-time monitoring and analysis. In the context of stamping press operations, a digital twin can simulate the entire production process, from the initial design to the final product, enabling manufacturers to optimize operations and improve decision-making.

Benefits of Digital Twin in Stamping Press Operations

Increased Efficiency

By utilizing a digital twin, manufacturers can streamline their stamping press operations. This technology allows for the identification of bottlenecks and inefficiencies in the production process, enabling quick adjustments that enhance overall productivity. For more insights on improving stamping efficiency, you can explore this quality control in stamping resource.

Enhanced Precision

The precision offered by a digital twin is unparalleled. By simulating every aspect of the stamping press operations, manufacturers can predict and mitigate potential issues before they arise. This leads to improved product quality and reduced waste.

Real-Time Monitoring and Control

With a digital twin, operators can monitor the stamping press in real-time. This level of control allows for immediate response to any deviations, ensuring consistent production quality. To learn more about operator training that complements this technology, visit operator training.

Implementing Digital Twin in Stamping Press Operations

Data Collection and Integration

The first step in implementing a digital twin is collecting accurate data from the stamping press operations. This includes machine parameters, production metrics, and environmental conditions. Integrating this data into a centralized system forms the backbone of the digital twin.

Simulation and Modeling

Using advanced software, manufacturers can create a detailed simulation of the stamping press. This model serves as a testbed for various scenarios, allowing operators to evaluate potential changes without disrupting actual operations.

Feedback Loop

A crucial component of a digital twin is the feedback loop. Continuous data collection and analysis provide insights into the performance of the stamping press. This feedback is used to refine and optimize the model, ensuring it accurately reflects the real-world operations.

Challenges and Considerations

Data Accuracy

The accuracy of the digital twin is directly dependent on the quality of the data collected. Inaccurate or incomplete data can lead to flawed simulations, resulting in suboptimal decisions.

Integration with Existing Systems

Integrating a digital twin into existing stamping press operations can be challenging. It requires seamless communication between different systems and departments, necessitating careful planning and coordination. For insights on new vs used equipment integration, check out this equipment comparison.

Cost and Investment

Implementing a digital twin involves significant investment in technology and training. However, the long-term benefits, including increased efficiency and reduced downtime, often outweigh the initial costs.

Digital Twin in Action

Case Study: Automotive Industry

In the automotive industry, digital twin technology has been successfully implemented in stamping press operations. By simulating the production line, manufacturers have achieved significant reductions in production time and defects.

Case Study: Aerospace Industry

The aerospace industry is another sector where digital twin technology has proven beneficial. By creating virtual models of complex components, manufacturers can ensure precision and compliance with stringent industry standards.

Future Trends and Developments

AI and Machine Learning Integration

As technology continues to advance, the integration of AI and machine learning with digital twin technology will become more prevalent. This will enhance predictive capabilities, allowing for even greater optimization of stamping press operations.

Expansion into Other Industries

While currently popular in automotive and aerospace, the application of digital twin technology is expected to expand into other industries, including consumer electronics and medical devices. For more on medical device stamping, visit this medical device stamping resource.

Conclusion

The adoption of digital twin technology in stamping press operations represents a significant step forward for industrial manufacturers. By leveraging this technology, companies can achieve increased efficiency, enhanced precision, and improved product quality. As the industry continues to evolve, the potential for digital twin technology is limitless, promising a future of innovation and growth.

FAQs

What is a digital twin?

A digital twin is a virtual replica of a physical system that allows for real-time monitoring and optimization.

How does a digital twin benefit stamping press operations?

It enhances efficiency, precision, and real-time control, leading to better product quality and reduced waste.

What industries can benefit from digital twin technology?

Industries such as automotive, aerospace, consumer electronics, and medical devices can benefit greatly from digital twin technology.

This article contains affiliate links. We may earn a commission at no extra cost to you.