In the world of industrial manufacturing, understanding the intricacies of die design for metal stamping can significantly impact production quality and efficiency. This article explores the foundational elements and advanced techniques involved in creating effective die designs, which are crucial for achieving precision and consistency in metal stamping processes.

Introduction to Metal Stamping

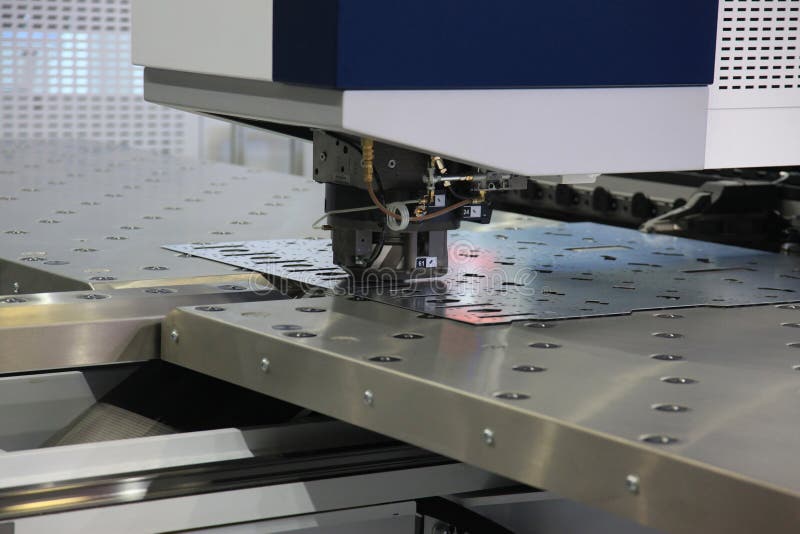

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It involves a combination of various operations such as punching, blanking, bending, and piercing. The efficiency and effectiveness of these processes largely depend on the quality of the die design.

Importance of Die Design

The die design plays a pivotal role in determining the dimensional accuracy and quality of the stamped parts. A well-designed die can help in minimizing material waste, reducing production costs, and ensuring the longevity of the stamping tool itself. In essence, the die design is the blueprint for the entire stamping process.

Key Components of Die Design

There are several essential components to consider when designing a die for metal stamping. These include the die block, punch, stripper plate, and the die set. Each component must be meticulously crafted to ensure they work harmoniously during the stamping process.

Types of Dies in Metal Stamping

Understanding the different types of dies is crucial for manufacturers. Common types include single-station dies, progressive dies, and transfer dies. Each type serves a specific purpose and is chosen based on the complexity and volume of the production.

Single-Station Dies

Single-station dies perform one operation per press stroke. They are ideal for low-volume production and simple part designs.

Progressive Dies

Progressive dies are used for high-volume production. They perform multiple operations in a single press stroke, enhancing efficiency and speed.

Transfer Dies

Transfer dies are suitable for complex parts that require multiple operations. The part is transferred from one station to another for different operations.

Materials Used in Die Design

The choice of material for die components is vital to withstand the stress and wear during the stamping process. Common materials include tool steels, carbide, and other hardened alloys.

Tool Steels

Tool steels are preferred for their hardness and durability. They are suitable for high-volume production due to their resistance to wear and deformation.

Carbide

Carbide is used in applications requiring extreme hardness and wear resistance. However, it is more expensive than tool steels.

Design Considerations for Dies

Several factors must be considered during the die design process, including the material properties of the workpiece, the complexity of the part design, and the intended production volume.

Material Properties

The material properties of the workpiece, such as its thickness, hardness, and ductility, will influence the die design. The die must be capable of handling these properties without compromising the quality of the stamped part.

Complexity of Part Design

Complex part designs require intricate die designs. The die must be able to perform multiple operations efficiently and consistently.

Production Volume

The intended production volume will influence the choice of die type and material. High-volume production requires durable materials and efficient die designs to minimize downtime and maintenance.

Advancements in Die Design

Recent advancements in technology have revolutionized die design. Computer-aided design (CAD) software and simulation tools are now commonly used to create precise and efficient die designs. These tools help in predicting potential issues and optimizing the design before production.

Challenges in Die Design for Metal Stamping

Designing a die for metal stamping is not without its challenges. Common challenges include material wear, die alignment, and maintaining dimensional accuracy. Addressing these challenges requires a deep understanding of the stamping process and the materials involved.

Future of Die Design in Metal Stamping

The future of die design in metal stamping looks promising with the continuous advancements in material science and technology. Innovations such as 3D printing and smart materials are expected to play a significant role in the evolution of die design, offering new possibilities for the manufacturing industry.

Conclusion

In conclusion, die design for metal stamping is a critical aspect of the manufacturing process that requires careful consideration and expertise. By understanding the components, types, materials, and design considerations, manufacturers can enhance the efficiency and quality of their stamping operations. For further reading on metal stamping, you can visit this external source and internal resource.

FAQs

What is the role of a die in metal stamping?

A die in metal stamping is a specialized tool used to cut and shape metal sheets into desired forms. It ensures precision and consistency in the stamping process.

How does die design impact production efficiency?

Die design directly impacts production efficiency by determining the speed, accuracy, and quality of the stamped parts. A well-designed die minimizes waste and reduces production costs.

What are progressive dies used for?

Progressive dies are used for high-volume production and are designed to perform multiple operations in a single press stroke, enhancing efficiency and speed.

This article contains affiliate links. We may earn a commission at no extra cost to you.