Ensuring precise cuts in your industrial applications is paramount. Whether you are involved in construction, carpentry, or metalwork, maintaining your tools to ensure they make precise cuts is essential. Proper tool maintenance not only enhances efficiency but also extends the lifespan of your equipment. In this article, we delve into the comprehensive guide on how industrial manufacturers can master tool maintenance for precise cuts.

Why Tool Maintenance is Critical for Precise Cuts

The importance of tool maintenance in delivering precise cuts cannot be overstated. Over time, wear and tear can lead to dull blades, misaligned tools, and ultimately, inaccurate cuts. Regular maintenance ensures that tools remain in good condition, avoiding unnecessary downtimes and saving costs associated with frequent replacements.

Understanding the Basics of Tool Maintenance

Tool maintenance encompasses various activities, each pivotal to ensuring precise cuts. This includes cleaning, sharpening, lubricating, and inspecting tools for defects. Each of these practices contributes to maintaining the integrity and functionality of the tool.

Cleaning Tools: The First Step

The simplest yet most effective maintenance practice is cleaning your tools after every use. Dust, debris, and residues can affect the performance and precision of your tools. Use a brush or compressed air to remove any particulate buildup on your equipment.

Sharpening Blades for Accuracy

Precise cuts are largely dependent on the sharpness of the tool being used. Sharpen blades regularly using a whetstone or a sharpening tool designed for your specific equipment. For guidance on achieving perfect edge retention, refer to this external resource.

Maintaining Alignment and Calibration

Alignment is crucial for precise cuts. Regular calibration checks ensure that the tools are properly aligned and functioning correctly. Misalignment can be corrected by adjusting bolts, screws, or guides specific to the machinery being used.

Importance of Lubrication

Friction can cause tools to wear out faster, affecting the precision of the cuts. Lubricate moving parts to ensure smooth operation and prolong the lifespan of your tools. Use manufacturer-recommended oils or greases and follow the application intervals as indicated.

Regular Inspection for Wear and Tear

Regular inspection is a fundamental practice in identifying signs of wear and tear early on. Check for any dents, cracks, or deformations that could impact the effectiveness of the tool. Replace any parts that are beyond repair to maintain high standards in your operations.

Innovations in Tool Maintenance

The advent of advanced technologies has brought new innovations in tool maintenance. Automated maintenance solutions and smart tools that provide real-time diagnostics are increasingly being used to enhance efficiency.

Tool Maintenance Practices in Different Industries

Each industry may require specific maintenance strategies tailored to its unique environment. Here, we discuss a few key sectors:

Carpentry and Woodworking

For carpentry, maintaining the sharpness of saw blades and ensuring the integrity of cutting angles are crucial for precise cuts. Consistent cleaning and sharpening routines should be followed.

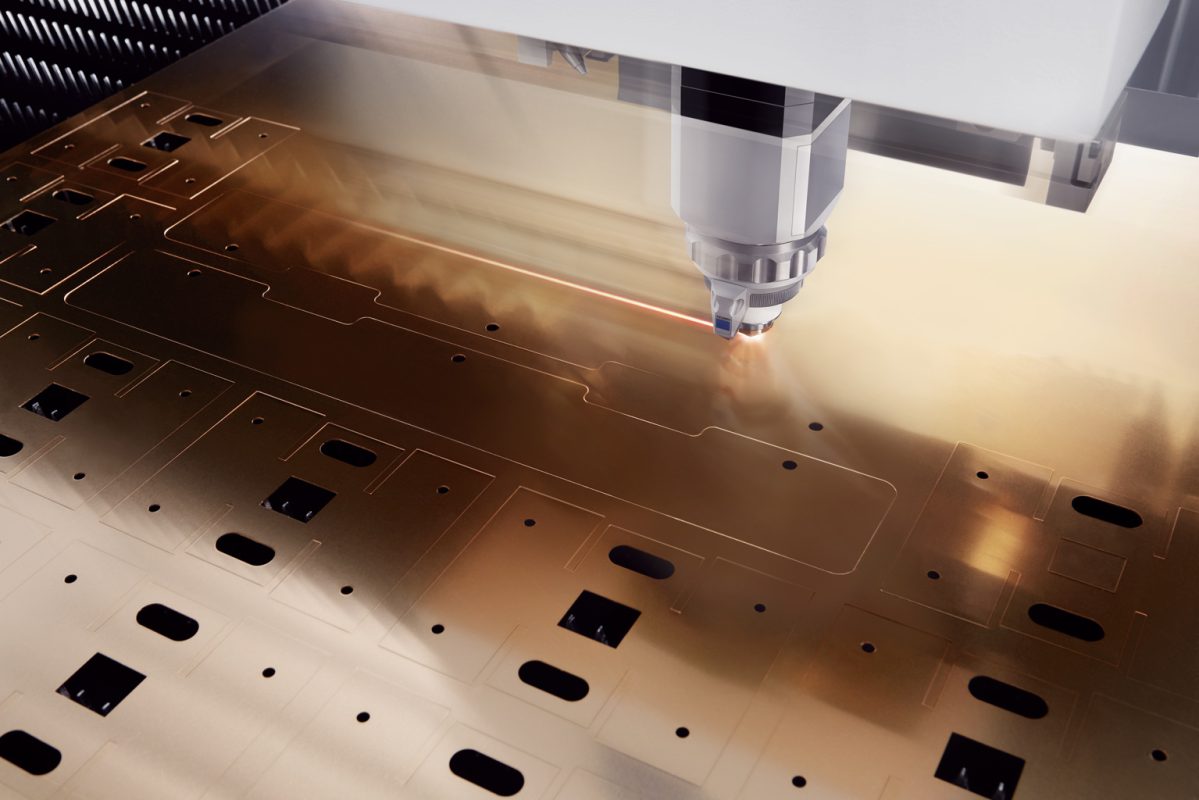

Metalworking

The metalworking industry relies heavily on precise cutting capabilities for their operations. Visit this internal link for more insights on crafting techniques crucial in metal fabrication.

Construction and Heavy Machinery

Construction tools endure high-impact usage, making regular checks and rigorous maintenance schedules vital. Ensure calibration and stability to maintain precision in large-scale projects.

Challenges in Maintaining Tools for Precision

Maintenance can be challenging due to varying tool types and the complexity of modern technology. Industrial settings often require professionals equipped with both knowledge and experience to handle such tasks efficiently.

Using Technology to Overcome Challenges

Leveraging technology in maintenance practices has proven beneficial. Tools equipped with digital interfaces offer insights and reminders for scheduled maintenance, thereby reducing human error.

FAQs on Tool Maintenance for Precise Cuts

How often should tools be sharpened?

Tools should be sharpened frequently if used daily. For casual use, regular assessments every few months are advisable.

What are the best practices for cleaning tools?

Regular cleaning using brushes or air compressors post-usage is ideal. It helps in preventing dust accumulation which may affect tool precision.

Can lubrication affect the outcome of precise cuts?

Yes, lubrication ensures smooth operation and precision of cuts by reducing unnecessary friction and wear. Always use recommended lubricants for optimal results.

Conclusion

Implementing a robust tool maintenance regime is an investment that yields significant returns in terms of precision and efficiency. Incorporate these practices into your daily operations to enhance performance and prolong the life of your tools. For further insights into precision cuts, you may explore additional resources like these fabrication techniques.

This article contains affiliate links. We may earn a commission at no extra cost to you.