In the world of industrial manufacturing, making decisions about cutting speed vs. power tradeoffs is crucial for efficiency and productivity. Whether you’re dealing with metals, plastics, or other materials, understanding these tradeoffs is essential. In this article, we will delve into the intricacies of cutting speed and power, aiming to provide a comprehensive understanding to manufacturers.

Understanding Cutting Speed

Cutting speed refers to the speed at which the cutting tool engages with the material. It’s a critical parameter in any machining process. The right cutting speed can lead to enhanced productivity, while the wrong speed can cause tool wear and material damage.

The Importance of Cutting Speed

Choosing the appropriate cutting speed is vital. It affects the surface finish, tool life, and machining time. Manufacturers must balance these factors to achieve optimal results.

Deciphering Power in Machining

Power in machining relates to the energy required to cut through a material. It influences the choice of tools and the overall efficiency of the operation. Understanding the power requirements can help in selecting suitable machinery and tools.

Balancing Power and Efficiency

While high power can speed up the process, it can also lead to increased wear and tear. Manufacturers need to find the right balance to maintain efficiency without compromising tool longevity.

The Interplay Between Cutting Speed and Power

There is a direct relationship between cutting speed and power. Increasing the cutting speed requires more power, which can affect the tool’s life and the quality of the cut. Understanding this relationship is crucial for optimizing the machining process.

Impact on Tool Life

High speeds and power can reduce tool life due to increased heat and friction. Manufacturers must consider these factors when planning their machining operations.

Material Considerations

Different materials react differently to changes in cutting speed and power. Metals like steel have different requirements compared to softer materials like plastic. It’s important to tailor the cutting speed and power to the specific material being machined.

Example: Cutting Carbon Steel

When cutting carbon steel, a balance between speed and power is essential to achieve a precise cut. The material’s hardness requires a specific approach to avoid tool damage.

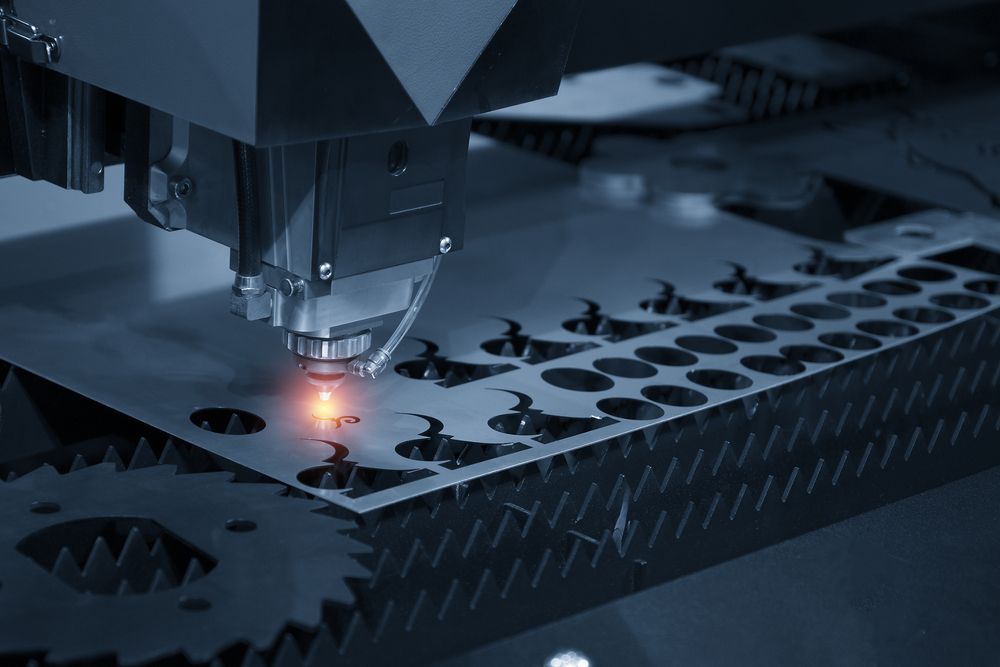

Technology’s Role in Optimizing Tradeoffs

Modern technology has introduced advanced tools and techniques that help manufacturers better manage cutting speed vs. power tradeoffs. CNC machines, for example, offer precise control over these parameters.

Benefits of CNC Machines

CNC machines provide precise adjustments, allowing for the optimization of cutting parameters based on real-time data, enhancing both cutting speed and power efficiency.

Case Study: Precision Metal Cutting

In a study conducted by Zintilon, manufacturers found that optimizing cutting speed and power significantly improved productivity without sacrificing quality.

Real-World Applications

Companies that successfully balance these trade-offs can produce better products faster, maintaining a competitive edge in the market.

Common Mistakes and How to Avoid Them

Manufacturers often make mistakes in balancing these parameters, leading to inefficiencies. Understanding common pitfalls can help avoid costly errors.

Overlooking Material Properties

Failing to consider material properties can lead to suboptimal results. It’s important to understand the material’s characteristics and adjust the cutting speed and power accordingly.

Future Trends in Cutting Speed and Power Management

As technology continues to evolve, new trends are emerging in the management of cutting speed and power. These advancements promise to further improve efficiency and productivity in manufacturing.

Smart Manufacturing Solutions

Innovations such as AI and IoT are paving the way for smarter manufacturing solutions that can dynamically adjust cutting parameters for optimal performance.

FAQs

What is the ideal cutting speed for different materials?

It varies by material. Metals generally require slower speeds compared to softer materials like plastic.

How does power consumption affect tool wear?

Higher power levels can increase wear due to heat and friction. Proper balance is crucial.

Can modern technology help in managing these tradeoffs?

Yes, modern technology like CNC machines and smart systems can optimize these parameters for better results.

This article contains affiliate links. We may earn a commission at no extra cost to you.