In the world of industrial manufacturing, the ability to cut small holes accurately is an essential skill. Whether you’re working with metals, plastics, or other materials, achieving precision in hole cutting can significantly impact the quality and functionality of the final product. This article will delve into the techniques and tools necessary to master this art, ensuring that your projects meet the highest standards of accuracy.

The Importance of Precision in Hole Cutting

Precision in cutting small holes is crucial for several reasons. Firstly, it ensures that components fit together correctly, which is vital for the structural integrity of the assembly. Secondly, precise cuts can prevent material wastage, saving both time and resources. Lastly, high accuracy in hole cutting can enhance the overall aesthetic of the finished product, particularly in industries where appearance matters, such as automotive and consumer electronics.

Understanding the Challenges

One of the main challenges in cutting small holes accurately is maintaining control over the tool and material. Factors such as tool sharpness, material thickness, and cutting speed can all affect the outcome. Additionally, variations in material properties, like hardness and flexibility, require different approaches to achieve the desired accuracy.

Tool Selection

Selecting the right tool is critical for successful hole cutting. For metals, tools like drill bits, laser cutters, and waterjet cutters are commonly used. Each tool has its advantages and limitations, and the choice depends on the material and the specific requirements of the project. For instance, laser cutters offer high precision and are suitable for thin materials, while waterjet cutters are ideal for thicker, tougher materials.

Material Considerations

Different materials respond differently to cutting processes. Metals like stainless steel and mild steel require distinct techniques due to their varying hardness. For more insights on this, visit cutting stainless vs mild steel. Plastics, on the other hand, may require slower cutting speeds to avoid melting or warping.

Techniques for Cutting Small Holes

There are several techniques available for cutting small holes, each suited to different materials and requirements.

Drilling

Drilling is a common method for creating holes in various materials. To achieve precision, it’s essential to use a sharp drill bit and maintain steady pressure. For metals, using cutting fluid can help reduce heat and prevent tool wear.

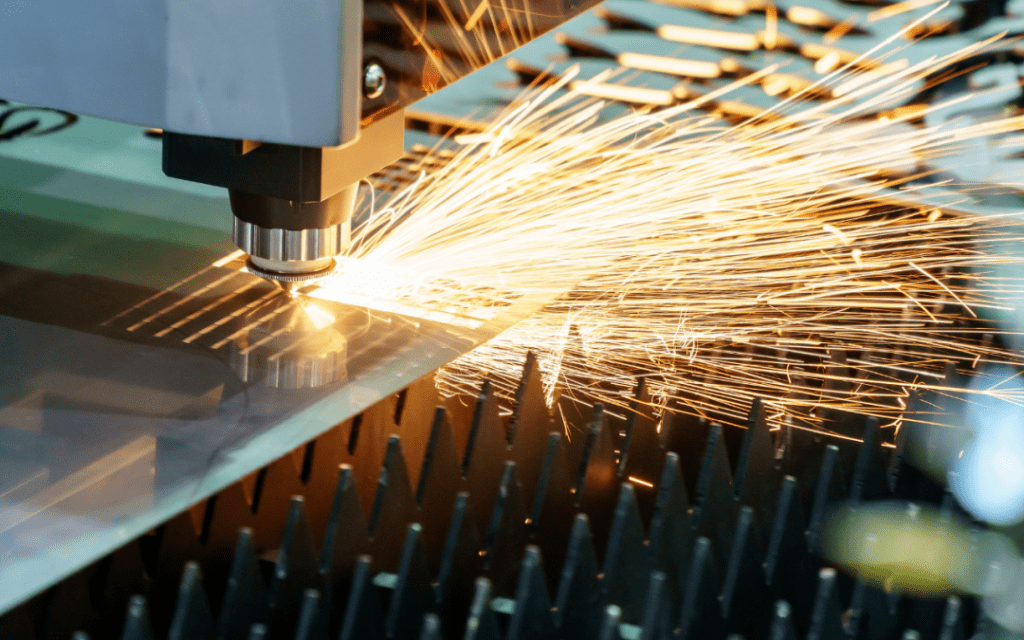

Laser Cutting

Laser cutting offers high precision and is ideal for intricate designs. It is particularly effective for thin materials and can produce clean, precise edges. However, it’s crucial to adjust the laser’s power and speed settings according to the material being cut.

Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through materials. This method is highly effective for thick or hard materials and does not generate heat, reducing the risk of material distortion.

CNC Machining

Computer Numerical Control (CNC) machining is a versatile method that offers high precision and repeatability. It is suitable for both metals and plastics, allowing for complex designs and tight tolerances. To learn more about the differences between CNC and manual cutting, check out CNC vs manual cutting.

Best Practices for Precision Cutting

To achieve the best results in cutting small holes accurately, consider the following best practices:

Tool Maintenance

Keeping your tools in optimal condition is essential for maintaining precision. Regularly inspect and sharpen blades and drill bits to ensure clean cuts. For troubleshooting cut quality issues, visit troubleshooting cut quality issues.

Proper Setup

Ensure that your workpiece is securely clamped and aligned before starting the cutting process. This helps prevent movement that could lead to inaccuracies.

Speed and Feed Rates

Adjust the speed and feed rates of your cutting tool based on the material and tool being used. Slower speeds may be necessary for hard materials, while faster speeds can be used for softer materials.

Case Study: Cutting Brass Cleanly

Brass is a popular material in various industries due to its aesthetic appeal and machinability. However, cutting brass cleanly requires specific techniques. For a detailed guide, refer to cutting brass cleanly.

Conclusion

Mastering the art of cutting small holes accurately is a valuable skill in the industrial sector. By understanding the challenges, selecting the right tools, and applying the appropriate techniques, you can achieve the precision needed to produce high-quality products. For a deeper understanding of precision metal cutting, visit this external guide.

FAQs

What are the main tools for cutting small holes?

Common tools include drill bits, laser cutters, waterjet cutters, and CNC machines.

How do I choose the right cutting method?

Consider the material type, thickness, and desired precision when selecting a cutting method.

Why is tool maintenance important?

Proper maintenance ensures tools remain sharp and effective, leading to more accurate cuts.

This article contains affiliate links. We may earn a commission at no extra cost to you.