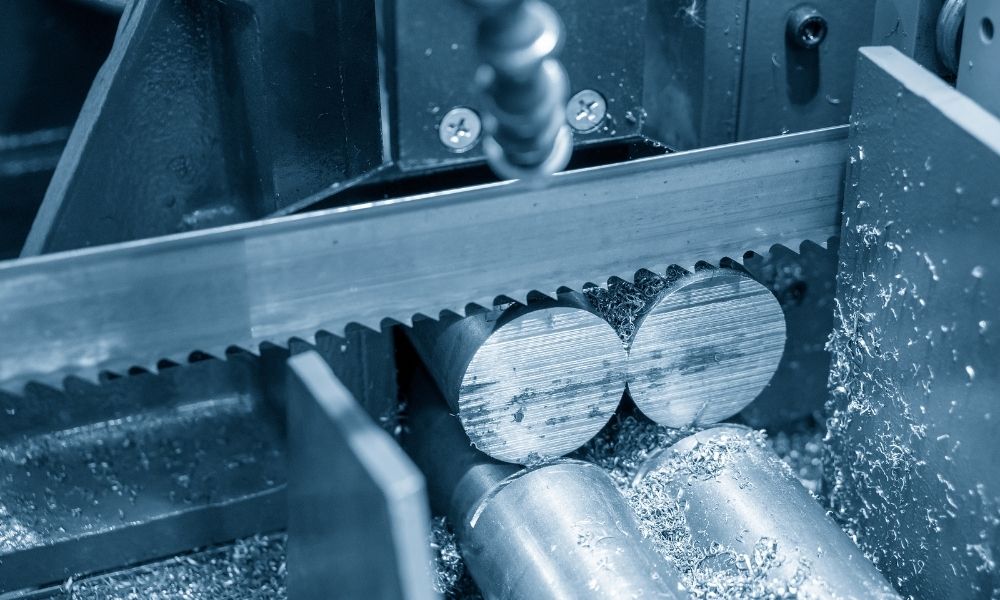

Cutting simulation software is revolutionizing the way industrial manufacturers approach precision cutting. With advancements in computational technology, this software provides a virtual environment to test and optimize cutting processes before they hit the production floor. This not only saves time but also significantly reduces material waste, making it a critical tool in modern manufacturing. For those who are unfamiliar, cutting simulation software allows engineers to model and simulate the cutting of materials in a virtual space, predicting outcomes with high accuracy.

The Importance of Precision in Industrial Manufacturing

In the world of manufacturing, precision is key. Whether you are working with metals, plastics or composites, the need for accurate cutting cannot be overstated. Cutting simulation software assists manufacturers in achieving this precision by allowing them to tweak parameters and foresee potential issues in the cutting process. This is especially beneficial in industries where tolerances are tight, and the cost of errors is high.

How Cutting Simulation Software Works

The core functionality of cutting simulation software lies in its ability to create a digital twin of the physical cutting process. It does so by using complex algorithms and mathematical models that mimic real-world physics. This allows manufacturers to test different cutting strategies and tools in a risk-free environment.

Benefits of Using Cutting Simulation Software

One of the primary advantages of using cutting simulation software is the ability to optimize cutting parameters. Users can adjust settings such as speed, feed rate, and tool path to identify the most efficient approach. Additionally, the software helps in reducing the trial-and-error phase that is typical in traditional manufacturing setups. By simulating the cutting process, manufacturers can predict challenges like tool wear and thermal effects, thereby enhancing the lifespan of cutting tools.

Applications in Various Industries

Cutting simulation software is not confined to one particular industry. It finds applications in aerospace, automotive, electronics, and even in complex fields like medical device manufacturing. Each industry has its unique requirements, and the software is versatile enough to accommodate these diverse needs.

Integration with Other Software Systems

Another exciting feature of modern cutting simulation software is its ability to integrate with other software systems. This includes CAD/CAM software, quality management systems, and even ERP systems. Such integration facilitates a seamless workflow, enhancing overall operational efficiency.

The Role of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are increasingly being incorporated into cutting simulation software. These technologies enable the software to learn from past simulations, continually improving its predictions and recommendations. This leads to better decision-making and increased productivity.

Challenges Faced by Manufacturers

Despite its numerous advantages, cutting simulation software is not without its challenges. One of the primary obstacles is the need for high computational power, which can be a barrier for smaller manufacturers. Additionally, there is a learning curve associated with mastering the software, requiring adequate training and expertise.

Overcoming Technical Hurdles

Manufacturers can overcome these challenges by investing in robust IT infrastructure and providing ongoing training for their workforce. Many software providers also offer cloud-based solutions, which mitigate the need for expensive hardware investments.

Future Trends in Cutting Simulation Software

The future of cutting simulation software looks promising, with continuous advancements in technology. The incorporation of virtual and augmented reality is on the horizon, offering even more immersive simulation experiences. Additionally, the trend towards Industry 4.0 will likely see even greater integration of these tools within the broader manufacturing ecosystem.

Conclusion: The Impact on Industrial Manufacturing

In conclusion, cutting simulation software is a game-changer for industrial manufacturing. It empowers manufacturers to achieve higher levels of precision and efficiency, ultimately leading to better product quality and reduced costs. As technology continues to evolve, the capabilities of this software will only expand, making it an indispensable tool for the future.

FAQ

What is cutting simulation software?

Cutting simulation software is a tool used to model and simulate the cutting process in a virtual environment. It allows manufacturers to optimize cutting parameters and predict challenges before actual production.

Why is precision important in manufacturing?

Precision is crucial in manufacturing because it ensures the final product meets quality standards and specifications. It reduces waste, improves efficiency, and minimizes costly errors.

How does AI enhance cutting simulation software?

AI enhances cutting simulation software by improving its predictive capabilities. It allows the software to learn from past simulations, leading to better decision-making and increased efficiency.

This article contains affiliate links. We may earn a commission at no extra cost to you.